Prva stran - WBC-INCO Net

Prva stran - WBC-INCO Net

Prva stran - WBC-INCO Net

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

B. Wind Turbine Characteristics<br />

A wind turbine turns the kinetic energy of the wind into<br />

mechanical energy. Wind passes over the blades exerting a<br />

turning force. The rotating blades turn a shaft inside the<br />

nacelle, which goes into a gearbox. The gearbox increases<br />

the rotation speed for the generator, which uses magnetic<br />

fields to convert the rotational energy into electrical energy<br />

It is very well known fact that the wind power P is<br />

proportional with the cube of the wind velocity v:<br />

1 3<br />

P = ρAv<br />

(1)<br />

2<br />

However, due to various losses the maximal usable wind<br />

power is equal to 59% of the theoretical value, which is<br />

known as a Betz coefficient. In the reality wind turbine<br />

efficiency is approximately 40%.<br />

There are several aspects considered at turbine design<br />

[4]:<br />

orientation of axes (vertical or horizontal),<br />

number of blades and<br />

types of rotor power regulation (pitch or stall).<br />

All modern turbines have horizontal axes, so this aspect<br />

will not be addressed in much more details.<br />

Most modern wind turbines are three-bladed designs with<br />

the rotor position maintained upwind. Two-bladed and onebladed<br />

wind turbine designs have the advantage of saving<br />

the cost of one or two rotor blade and lower turbine weight.<br />

However, they require higher rotational speed to yield the<br />

same energy output. This is a disadvantage both in regard to<br />

noise and visual intrusion.<br />

There are two principal means of limiting rotor power in<br />

high operational wind speeds - stall regulation and pitch<br />

regulation. Stall regulated machines require speed<br />

regulation. As wind speed increases, providing the rotor<br />

speed is held constant, flow angles over the blade sections<br />

become steeper. The blades become increasingly stalled and<br />

this limits power to acceptable levels without any additional<br />

active control. For this to work, the speed of the rotor must<br />

be held essentially constant, which is achieved through the<br />

connection of the electric generator to the grid. Briefly, a<br />

stall regulated wind turbine will run at approximately<br />

constant speed in high wind, not producing excessive power<br />

and yet achieving this without any change to rotor<br />

geometry. Pitch regulation involves turning the blades about<br />

their long axis (pitching the blades) to regulate the power<br />

extracted by the rotor. In contrast to stall regulation, pitch<br />

regulation requires changes to rotor geometry. This involves<br />

an active control system to sense blade position, measure<br />

output power and instruct appropriate changes of blade<br />

pitch. The objective of pitch regulation is similar to stall<br />

regulation, namely to regulate output power in high<br />

operational wind speeds. For pitch and stall, costs are quite<br />

similar for each design type, but pitch regulation offers<br />

potentially better output power quality and pitch regulation<br />

with independent operation of each pitch actuator allows the<br />

rotor to be regarded as two independent braking systems for<br />

certification purposes.<br />

The latest developments of wind turbine technology are<br />

directed towards turbines with higher rated power especially<br />

for off-shore applications, larger rotor diameter,<br />

development of new materials for lower blades mass,<br />

increased “grid friendliness” (variable speed drive) and offshore<br />

applications.<br />

C. Electricity Production from Wind Energy<br />

Annual amount of produced electricity should be<br />

calculated according to expected wind characteristics. Total<br />

electricity produced from wind turbine ET in specific time<br />

period T depends on the wind velocities v and is determined<br />

by the following equation:<br />

∞<br />

E = T∫<br />

Pv<br />

0<br />

T p(<br />

v)<br />

dv<br />

(2),<br />

where Pv denotes wind turbine power at wind velocity v and<br />

p(v) is Weibull wind velocity probability distribution<br />

function.<br />

Apart from windiness of the site, the amount of<br />

electricity produced from a wind turbine depends also on<br />

wind turbine availability, which denotes the capability to<br />

operate when the wind is blowing and is typically 98% or<br />

above and on the way the turbines are arranged (the ideal<br />

position for a wind turbine generator is a smooth hill top,<br />

with a flat clear fetch, at least in the prevailing wind<br />

direction).<br />

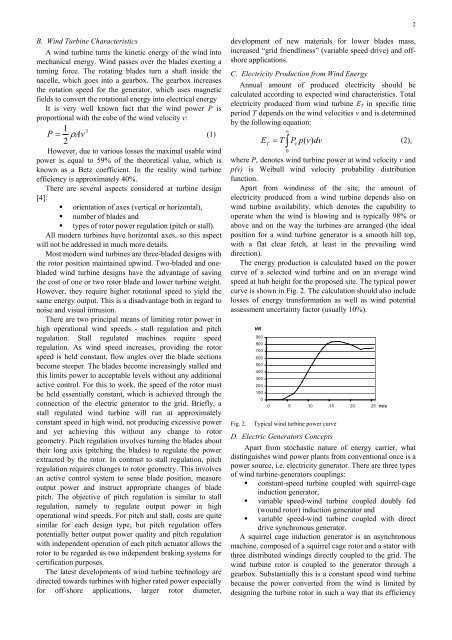

The energy production is calculated based on the power<br />

curve of a selected wind turbine and on an average wind<br />

speed at hub height for the proposed site. The typical power<br />

curve is shown in Fig. 2. The calculation should also include<br />

losses of energy transformation as well as wind potential<br />

assessment uncertainty factor (usually 10%).<br />

kW<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

0 5 10 15 20 25 m/s<br />

Fig. 2. Typical wind turbine power curve<br />

D. Electric Generators Concepts<br />

Apart from stochastic nature of energy carrier, what<br />

distinguishes wind power plants from conventional once is a<br />

power source, i.e. electricity generator. There are three types<br />

of wind turbine-generators couplings:<br />

constant-speed turbine coupled with squirrel-cage<br />

induction generator,<br />

variable speed-wind turbine coupled doubly fed<br />

(wound rotor) induction generator and<br />

variable speed-wind turbine coupled with direct<br />

drive synchronous generator.<br />

A squirrel cage induction generator is an asynchronous<br />

machine, composed of a squirrel cage rotor and a stator with<br />

three distributed windings directly coupled to the grid. The<br />

wind turbine rotor is coupled to the generator through a<br />

gearbox. Substantially this is a constant speed wind turbine<br />

because the power converted from the wind is limited by<br />

designing the turbine rotor in such a way that its efficiency<br />

2