4 - Fagor Automation

4 - Fagor Automation

4 - Fagor Automation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1.<br />

MILLING CANNED CYCLES.<br />

General concepts<br />

CNC 8065<br />

(REF: 1209)<br />

·30·<br />

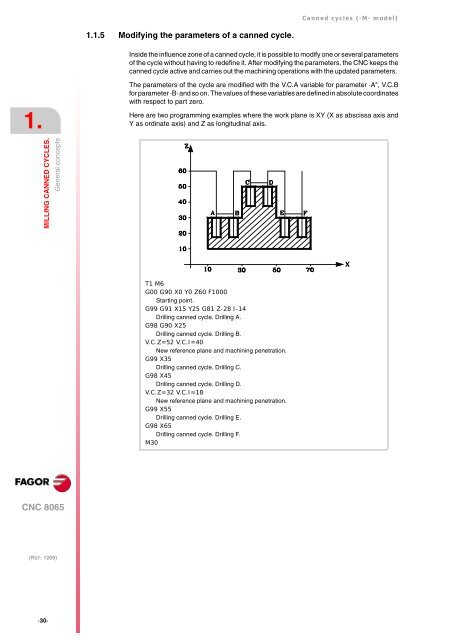

1.1.5 Modifying the parameters of a canned cycle.<br />

Canned cycles (·M· model)<br />

Inside the influence zone of a canned cycle, it is possible to modify one or several parameters<br />

of the cycle without having to redefine it. After modifying the parameters, the CNC keeps the<br />

canned cycle active and carries out the machining operations with the updated parameters.<br />

The parameters of the cycle are modified with the V.C.A variable for parameter ·A", V.C.B<br />

for parameter ·B· and so on. The values of these variables are defined in absolute coordinates<br />

with respect to part zero.<br />

Here are two programming examples where the work plane is XY (X as abscissa axis and<br />

Y as ordinate axis) and Z as longitudinal axis.<br />

T1 M6<br />

G00 G90 X0 Y0 Z60 F1000<br />

Starting point.<br />

G99 G91 X15 Y25 G81 Z-28 I-14<br />

Drilling canned cycle. Drilling A.<br />

G98 G90 X25<br />

Drilling canned cycle. Drilling B.<br />

V.C.Z=52 V.C.I=40<br />

New reference plane and machining penetration.<br />

G99 X35<br />

Drilling canned cycle. Drilling C.<br />

G98 X45<br />

Drilling canned cycle. Drilling D.<br />

V.C.Z=32 V.C.I=18<br />

New reference plane and machining penetration.<br />

G99 X55<br />

Drilling canned cycle. Drilling E.<br />

G98 X65<br />

Drilling canned cycle. Drilling F.<br />

M30