4 - Fagor Automation

4 - Fagor Automation

4 - Fagor Automation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1.<br />

MILLING CANNED CYCLES.<br />

CNC 8065<br />

(REF: 1209)<br />

·38·<br />

G83. Deep-hole drilling canned cycle with constant peck<br />

Canned cycles (·M· model)<br />

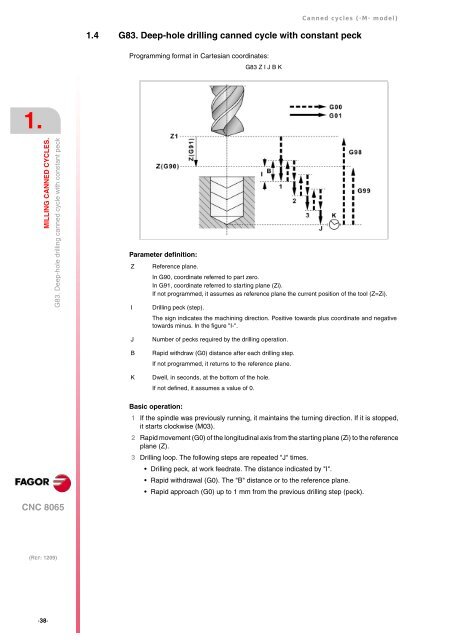

1.4 G83. Deep-hole drilling canned cycle with constant peck<br />

Programming format in Cartesian coordinates:<br />

Parameter definition:<br />

G83 Z I J B K<br />

Z Reference plane.<br />

In G90, coordinate referred to part zero.<br />

In G91, coordinate referred to starting plane (Zi).<br />

If not programmed, it assumes as reference plane the current position of the tool (Z=Zi).<br />

I Drilling peck (step).<br />

The sign indicates the machining direction. Positive towards plus coordinate and negative<br />

towards minus. In the figure "I-".<br />

J Number of pecks required by the drilling operation.<br />

B Rapid withdraw (G0) distance after each drilling step.<br />

If not programmed, it returns to the reference plane.<br />

K Dwell, in seconds, at the bottom of the hole.<br />

If not defined, it assumes a value of 0.<br />

Basic operation:<br />

1 If the spindle was previously running, it maintains the turning direction. If it is stopped,<br />

it starts clockwise (M03).<br />

2 Rapid movement (G0) of the longitudinal axis from the starting plane (Zi) to the reference<br />

plane (Z).<br />

3 Drilling loop. The following steps are repeated "J" times.<br />

Drilling peck, at work feedrate. The distance indicated by "I".<br />

Rapid withdrawal (G0). The "B" distance or to the reference plane.<br />

Rapid approach (G0) up to 1 mm from the previous drilling step (peck).