Sampling Guide for Air Contaminants in the Workplace - Irsst

Sampling Guide for Air Contaminants in the Workplace - Irsst

Sampling Guide for Air Contaminants in the Workplace - Irsst

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

IRSST – <strong>Sampl<strong>in</strong>g</strong> <strong>Guide</strong> <strong>for</strong> <strong>Air</strong> <strong>Contam<strong>in</strong>ants</strong> <strong>in</strong> <strong>the</strong> <strong>Workplace</strong> 33<br />

2.7 Description of <strong>the</strong> sampl<strong>in</strong>g systems<br />

Evaluation of an air contam<strong>in</strong>ant requires a system <strong>for</strong> collect<strong>in</strong>g a given volume of air, a collect<strong>in</strong>g medium,<br />

and an analytical method. It generally <strong>in</strong>cludes <strong>the</strong> follow<strong>in</strong>g components: pump, tube, cassette-filter unit,<br />

cyclone, etc. Calibration of a sampl<strong>in</strong>g system, mean<strong>in</strong>g <strong>the</strong> adjustment of <strong>the</strong> air flow through it requires <strong>the</strong><br />

use of a flow meter and will depend on <strong>the</strong> pump and ambient conditions on <strong>the</strong> sampl<strong>in</strong>g site and calibration<br />

site. The follow<strong>in</strong>g sections describe <strong>the</strong> flow meters and pumps most commonly used <strong>in</strong> <strong>in</strong>dustrial hygiene<br />

and discuss <strong>the</strong> effects of temperature and pressure on <strong>the</strong>ir mechanism and on <strong>the</strong>ir calibration.<br />

2.7.1 <strong>Sampl<strong>in</strong>g</strong> pumps<br />

Pumps are <strong>the</strong> devices most commonly used <strong>in</strong> <strong>in</strong>dustrial hygiene <strong>for</strong> sampl<strong>in</strong>g a known volume of air <strong>for</strong> <strong>the</strong><br />

purpose of determ<strong>in</strong><strong>in</strong>g <strong>the</strong> concentration of <strong>the</strong> contam<strong>in</strong>ants present. The pumps most used are high flow,<br />

low flow, and very high flow pumps.<br />

2.7.1.1 Personal pumps<br />

Personal sampl<strong>in</strong>g pumps are classified <strong>in</strong> two categories: pumps with low flow rates which generally operate<br />

<strong>in</strong> <strong>the</strong> 1 to 500 mL/m<strong>in</strong> range, and high-flow pumps which operate from 1.0 to 5.0 L/m<strong>in</strong>. They operate<br />

<strong>in</strong>dependently due to rechargeable batteries, thus ensur<strong>in</strong>g at least 8 consecutive hours of sampl<strong>in</strong>g dur<strong>in</strong>g <strong>the</strong><br />

work period.<br />

Use of a pump assumes periodic verification of <strong>the</strong> flow rate <strong>in</strong> order to ensure that it rema<strong>in</strong>s constant.<br />

Generally, <strong>the</strong> flow control mechanisms on some pumps are designed to ma<strong>in</strong>ta<strong>in</strong> this constant flow despite<br />

<strong>the</strong> drop <strong>in</strong> battery voltage and normal clogg<strong>in</strong>g of <strong>the</strong> collect<strong>in</strong>g medium. Flow checks, at least at <strong>the</strong> start<br />

and end of sampl<strong>in</strong>g, are used to determ<strong>in</strong>e <strong>the</strong> average flow and, if need be, to detect poor function<strong>in</strong>g of <strong>the</strong><br />

pump. The difference between <strong>the</strong>se flow measurements must be less than 5% (21).<br />

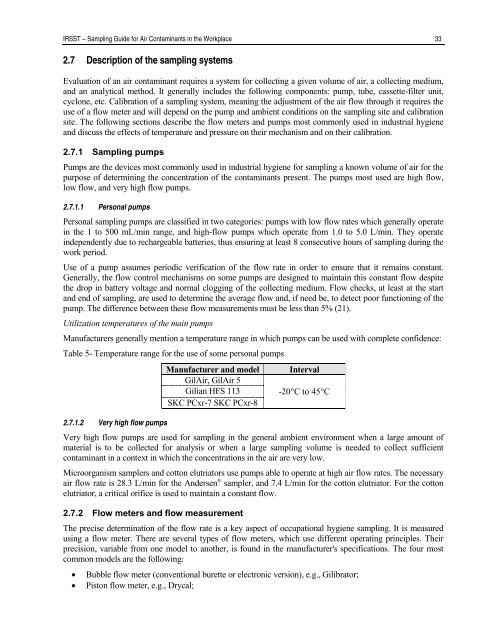

Utilization temperatures of <strong>the</strong> ma<strong>in</strong> pumps<br />

Manufacturers generally mention a temperature range <strong>in</strong> which pumps can be used with complete confidence:<br />

Table 5- Temperature range <strong>for</strong> <strong>the</strong> use of some personal pumps<br />

2.7.1.2 Very high flow pumps<br />

Manufacturer and model<br />

Gil<strong>Air</strong>, Gil<strong>Air</strong> 5<br />

Gilian HFS 113<br />

SKC PCxr-7 SKC PCxr-8<br />

Interval<br />

-20°C to 45°C<br />

Very high flow pumps are used <strong>for</strong> sampl<strong>in</strong>g <strong>in</strong> <strong>the</strong> general ambient environment when a large amount of<br />

material is to be collected <strong>for</strong> analysis or when a large sampl<strong>in</strong>g volume is needed to collect sufficient<br />

contam<strong>in</strong>ant <strong>in</strong> a context <strong>in</strong> which <strong>the</strong> concentrations <strong>in</strong> <strong>the</strong> air are very low.<br />

Microorganism samplers and cotton elutriators use pumps able to operate at high air flow rates. The necessary<br />

air flow rate is 28.3 L/m<strong>in</strong> <strong>for</strong> <strong>the</strong> Andersen ® sampler, and 7.4 L/m<strong>in</strong> <strong>for</strong> <strong>the</strong> cotton elutriator. For <strong>the</strong> cotton<br />

elutriator, a critical orifice is used to ma<strong>in</strong>ta<strong>in</strong> a constant flow.<br />

2.7.2 Flow meters and flow measurement<br />

The precise determ<strong>in</strong>ation of <strong>the</strong> flow rate is a key aspect of occupational hygiene sampl<strong>in</strong>g. It is measured<br />

us<strong>in</strong>g a flow meter. There are several types of flow meters, which use different operat<strong>in</strong>g pr<strong>in</strong>ciples. Their<br />

precision, variable from one model to ano<strong>the</strong>r, is found <strong>in</strong> <strong>the</strong> manufacturer's specifications. The four most<br />

common models are <strong>the</strong> follow<strong>in</strong>g:<br />

• Bubble flow meter (conventional burette or electronic version), e.g., Gilibrator;<br />

• Piston flow meter, e.g., Drycal;