5800 Refrigerated Sampler Service Guide - Isco

5800 Refrigerated Sampler Service Guide - Isco

5800 Refrigerated Sampler Service Guide - Isco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>5800</strong> <strong>Refrigerated</strong> <strong>Sampler</strong> <strong>Service</strong> <strong>Guide</strong><br />

Section 3 Refrigeration System<br />

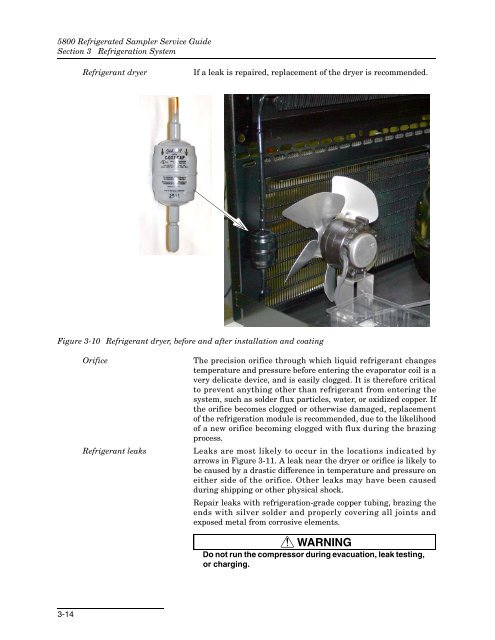

Refrigerant dryer<br />

If a leak is repaired, replacement of the dryer is recommended.<br />

Figure 3-10 Refrigerant dryer, before and after installation and coating<br />

Orifice<br />

Refrigerant leaks<br />

The precision orifice through which liquid refrigerant changes<br />

temperature and pressure before entering the evaporator coil is a<br />

very delicate device, and is easily clogged. It is therefore critical<br />

to prevent anything other than refrigerant from entering the<br />

system, such as solder flux particles, water, or oxidized copper. If<br />

the orifice becomes clogged or otherwise damaged, replacement<br />

of the refrigeration module is recommended, due to the likelihood<br />

of a new orifice becoming clogged with flux during the brazing<br />

process.<br />

Leaks are most likely to occur in the locations indicated by<br />

arrows in Figure 3-11. A leak near the dryer or orifice is likely to<br />

be caused by a drastic difference in temperature and pressure on<br />

either side of the orifice. Other leaks may have been caused<br />

during shipping or other physical shock.<br />

Repair leaks with refrigeration-grade copper tubing, brazing the<br />

ends with silver solder and properly covering all joints and<br />

exposed metal from corrosive elements.<br />

WARNING<br />

Do not run the compressor during evacuation, leak testing,<br />

or charging.<br />

3-14