(MERAF) for the Base Metals Smelting Sector - CCME

(MERAF) for the Base Metals Smelting Sector - CCME

(MERAF) for the Base Metals Smelting Sector - CCME

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

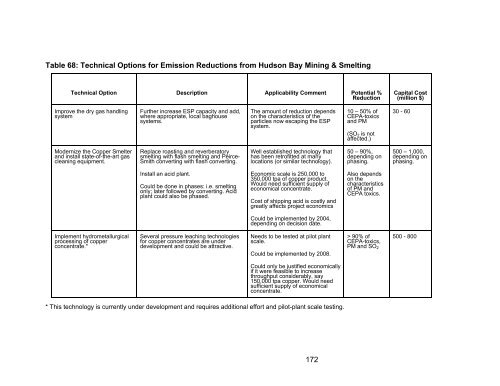

Table 68: Technical Options <strong>for</strong> Emission Reductions from Hudson Bay Mining & <strong>Smelting</strong><br />

Technical Option Description Applicability Comment Potential %<br />

Reduction<br />

Capital Cost<br />

(million $)<br />

Improve <strong>the</strong> dry gas handling<br />

system<br />

Fur<strong>the</strong>r increase ESP capacity and add,<br />

where appropriate, local baghouse<br />

systems.<br />

The amount of reduction depends<br />

on <strong>the</strong> characteristics of <strong>the</strong><br />

particles now escaping <strong>the</strong> ESP<br />

system.<br />

10 – 50% of<br />

CEPA-toxics<br />

and PM<br />

(SO 2 is not<br />

affected.)<br />

30 - 60<br />

Modernize <strong>the</strong> Copper Smelter<br />

and install state-of-<strong>the</strong>-art gas<br />

cleaning equipment.<br />

Replace roasting and reverberatory<br />

smelting with flash smelting and Peirce-<br />

Smith converting with flash converting.<br />

Well established technology that<br />

has been retrofitted at many<br />

locations (or similar technology).<br />

50 – 90%,<br />

depending on<br />

phasing.<br />

500 – 1,000,<br />

depending on<br />

phasing.<br />

Install an acid plant.<br />

Could be done in phases: i.e. smelting<br />

only; later followed by converting. Acid<br />

plant could also be phased.<br />

Economic scale is 250,000 to<br />

350,000 tpa of copper product.<br />

Would need sufficient supply of<br />

economical concentrate.<br />

Cost of shipping acid is costly and<br />

greatly affects project economics<br />

Also depends<br />

on <strong>the</strong><br />

characteristics<br />

of PM and<br />

CEPA toxics.<br />

Could be implemented by 2004,<br />

depending on decision date.<br />

Implement hydrometallurgical<br />

processing of copper<br />

concentrate.*<br />

Several pressure leaching technologies<br />

<strong>for</strong> copper concentrates are under<br />

development and could be attractive.<br />

Needs to be tested at pilot plant<br />

scale.<br />

Could be implemented by 2008.<br />

> 90% of 500 - 800<br />

CEPA-toxics,<br />

PM and SO 2<br />

Could only be justified economically<br />

if it were feasible to increase<br />

throughput considerably, say<br />

150,000 tpa copper. Would need<br />

sufficient supply of economical<br />

concentrate.<br />

* This technology is currently under development and requires additional ef<strong>for</strong>t and pilot-plant scale testing.<br />

172