(MERAF) for the Base Metals Smelting Sector - CCME

(MERAF) for the Base Metals Smelting Sector - CCME

(MERAF) for the Base Metals Smelting Sector - CCME

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

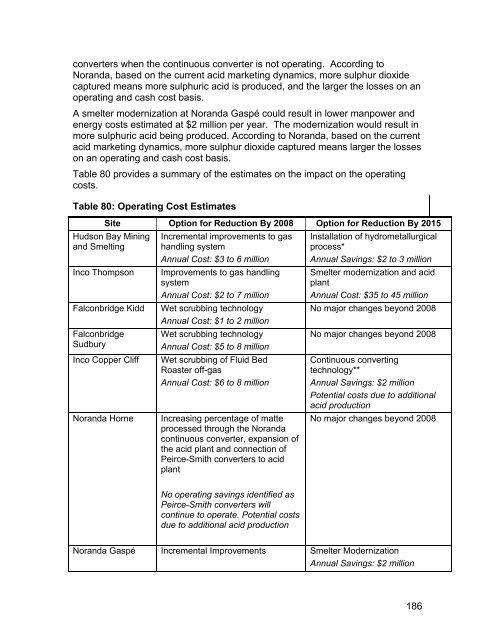

converters when <strong>the</strong> continuous converter is not operating. According to<br />

Noranda, based on <strong>the</strong> current acid marketing dynamics, more sulphur dioxide<br />

captured means more sulphuric acid is produced, and <strong>the</strong> larger <strong>the</strong> losses on an<br />

operating and cash cost basis.<br />

A smelter modernization at Noranda Gaspé could result in lower manpower and<br />

energy costs estimated at $2 million per year. The modernization would result in<br />

more sulphuric acid being produced. According to Noranda, based on <strong>the</strong> current<br />

acid marketing dynamics, more sulphur dioxide captured means larger <strong>the</strong> losses<br />

on an operating and cash cost basis.<br />

Table 80 provides a summary of <strong>the</strong> estimates on <strong>the</strong> impact on <strong>the</strong> operating<br />

costs.<br />

Table 80: Operating Cost Estimates<br />

Site Option <strong>for</strong> Reduction By 2008 Option <strong>for</strong> Reduction By 2015<br />

Hudson Bay Mining<br />

and <strong>Smelting</strong><br />

Inco Thompson<br />

Falconbridge Kidd<br />

Falconbridge<br />

Sudbury<br />

Inco Copper Cliff<br />

Noranda Horne<br />

Incremental improvements to gas<br />

handling system<br />

Annual Cost: $3 to 6 million<br />

Improvements to gas handling<br />

system<br />

Annual Cost: $2 to 7 million<br />

Wet scrubbing technology<br />

Annual Cost: $1 to 2 million<br />

Wet scrubbing technology<br />

Annual Cost: $5 to 8 million<br />

Wet scrubbing of Fluid Bed<br />

Roaster off-gas<br />

Annual Cost: $6 to 8 million<br />

Increasing percentage of matte<br />

processed through <strong>the</strong> Noranda<br />

continuous converter, expansion of<br />

<strong>the</strong> acid plant and connection of<br />

Peirce-Smith converters to acid<br />

plant<br />

Installation of hydrometallurgical<br />

process*<br />

Annual Savings: $2 to 3 million<br />

Smelter modernization and acid<br />

plant<br />

Annual Cost: $35 to 45 million<br />

No major changes beyond 2008<br />

No major changes beyond 2008<br />

Continuous converting<br />

technology**<br />

Annual Savings: $2 million<br />

Potential costs due to additional<br />

acid production<br />

No major changes beyond 2008<br />

No operating savings identified as<br />

Peirce-Smith converters will<br />

continue to operate. Potential costs<br />

due to additional acid production<br />

Noranda Gaspé Incremental Improvements Smelter Modernization<br />

Annual Savings: $2 million<br />

186