(MERAF) for the Base Metals Smelting Sector - CCME

(MERAF) for the Base Metals Smelting Sector - CCME

(MERAF) for the Base Metals Smelting Sector - CCME

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

In addition to <strong>the</strong>se measures, Hatch Associates has estimated that a 10%<br />

reduction in emissions was feasible from <strong>the</strong> facilities not analyzed. This 10%<br />

reduction <strong>for</strong> <strong>the</strong> “Rest of <strong>Sector</strong>” is assumed to be <strong>for</strong> <strong>the</strong> total releases <strong>for</strong> all<br />

<strong>the</strong> facilities not specifically identified, not <strong>for</strong> each individual facility<br />

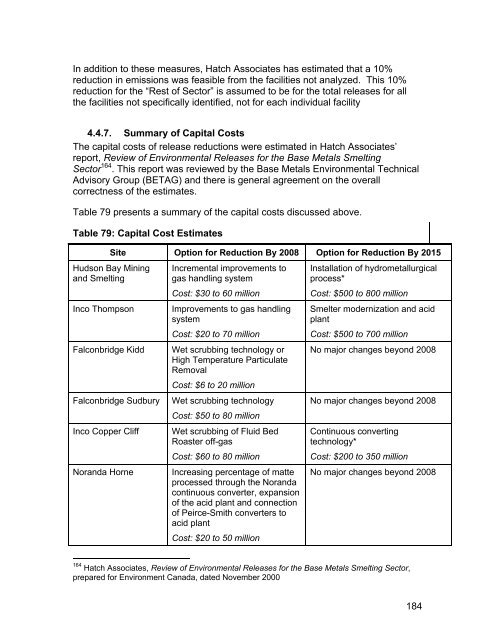

4.4.7. Summary of Capital Costs<br />

The capital costs of release reductions were estimated in Hatch Associates’<br />

report, Review of Environmental Releases <strong>for</strong> <strong>the</strong> <strong>Base</strong> <strong>Metals</strong> <strong>Smelting</strong><br />

<strong>Sector</strong> 164 . This report was reviewed by <strong>the</strong> <strong>Base</strong> <strong>Metals</strong> Environmental Technical<br />

Advisory Group (BETAG) and <strong>the</strong>re is general agreement on <strong>the</strong> overall<br />

correctness of <strong>the</strong> estimates.<br />

Table 79 presents a summary of <strong>the</strong> capital costs discussed above.<br />

Table 79: Capital Cost Estimates<br />

Site Option <strong>for</strong> Reduction By 2008 Option <strong>for</strong> Reduction By 2015<br />

Hudson Bay Mining<br />

and <strong>Smelting</strong><br />

Inco Thompson<br />

Falconbridge Kidd<br />

Falconbridge Sudbury<br />

Inco Copper Cliff<br />

Noranda Horne<br />

Incremental improvements to<br />

gas handling system<br />

Cost: $30 to 60 million<br />

Improvements to gas handling<br />

system<br />

Cost: $20 to 70 million<br />

Wet scrubbing technology or<br />

High Temperature Particulate<br />

Removal<br />

Cost: $6 to 20 million<br />

Wet scrubbing technology<br />

Cost: $50 to 80 million<br />

Wet scrubbing of Fluid Bed<br />

Roaster off-gas<br />

Cost: $60 to 80 million<br />

Increasing percentage of matte<br />

processed through <strong>the</strong> Noranda<br />

continuous converter, expansion<br />

of <strong>the</strong> acid plant and connection<br />

of Peirce-Smith converters to<br />

acid plant<br />

Cost: $20 to 50 million<br />

Installation of hydrometallurgical<br />

process*<br />

Cost: $500 to 800 million<br />

Smelter modernization and acid<br />

plant<br />

Cost: $500 to 700 million<br />

No major changes beyond 2008<br />

No major changes beyond 2008<br />

Continuous converting<br />

technology*<br />

Cost: $200 to 350 million<br />

No major changes beyond 2008<br />

164 Hatch Associates, Review of Environmental Releases <strong>for</strong> <strong>the</strong> <strong>Base</strong> <strong>Metals</strong> <strong>Smelting</strong> <strong>Sector</strong>,<br />

prepared <strong>for</strong> Environment Canada, dated November 2000<br />

184