(MERAF) for the Base Metals Smelting Sector - CCME

(MERAF) for the Base Metals Smelting Sector - CCME

(MERAF) for the Base Metals Smelting Sector - CCME

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4.4.4. Inco Limited, Sudbury/Copper Cliff Operations, Copper Cliff,<br />

Ontario<br />

The following process and environmental control options might possible fur<strong>the</strong>r<br />

reduce air emissions:<br />

• Wet scrubbing of off-gas from <strong>the</strong> Fluid Bed Roaster in <strong>the</strong> smelter, and<br />

recovery of SO 2 to produce sulphuric acid.<br />

• Optimize or replace electrostatic precipitator (ESP #5) used <strong>for</strong> off-gas<br />

from converting.<br />

• The implementation of continuous converting of flash furnace matte,<br />

wet scrubbing of <strong>the</strong> process gases and recovery of S0 2 <strong>for</strong> sulphuric<br />

acid production. This would be substantially more costly than <strong>the</strong> first<br />

option, but would result in a very much larger reduction of emissions.<br />

Inco Copper Cliff was required under a Control Order from <strong>the</strong> Ontario Ministry of<br />

Environment to study technically and economically feasible ways to reduce<br />

sulphur dioxide emissions to 175,000 tonnes per year. A study was submitted to<br />

<strong>the</strong> MOE in 1999. Fluidized Bed Roaster off-gas scrubbing was identified as <strong>the</strong><br />

most promising option to achieved this reduction.<br />

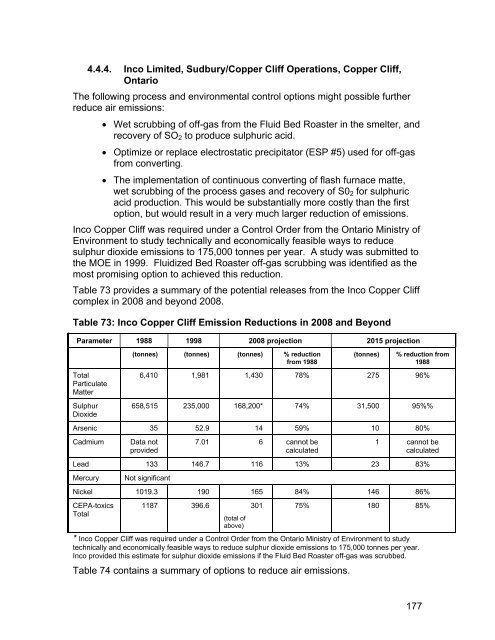

Table 73 provides a summary of <strong>the</strong> potential releases from <strong>the</strong> Inco Copper Cliff<br />

complex in 2008 and beyond 2008.<br />

Table 73: Inco Copper Cliff Emission Reductions in 2008 and Beyond<br />

Parameter 1988 1998 2008 projection 2015 projection<br />

Total<br />

Particulate<br />

Matter<br />

Sulphur<br />

Dioxide<br />

(tonnes) (tonnes) (tonnes) % reduction<br />

from 1988<br />

(tonnes)<br />

% reduction from<br />

1988<br />

6,410 1,981 1,430 78% 275 96%<br />

658,515 235,000 168,200* 74% 31,500 95%%<br />

Arsenic 35 52.9 14 59% 10 80%<br />

Cadmium<br />

Data not<br />

provided<br />

7.01 6 cannot be<br />

calculated<br />

1 cannot be<br />

calculated<br />

Lead 133 146.7 116 13% 23 83%<br />

Mercury<br />

Not significant<br />

Nickel 1019.3 190 165 84% 146 86%<br />

CEPA-toxics<br />

Total<br />

1187 396.6 301<br />

(total of<br />

above)<br />

75% 180 85%<br />

* Inco Copper Cliff was required under a Control Order from <strong>the</strong> Ontario Ministry of Environment to study<br />

technically and economically feasible ways to reduce sulphur dioxide emissions to 175,000 tonnes per year.<br />

Inco provided this estimate <strong>for</strong> sulphur dioxide emissions if <strong>the</strong> Fluid Bed Roaster off-gas was scrubbed.<br />

Table 74 contains a summary of options to reduce air emissions.<br />

177