Student Project Abstracts 2005 - Pluto - University of Washington

Student Project Abstracts 2005 - Pluto - University of Washington

Student Project Abstracts 2005 - Pluto - University of Washington

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

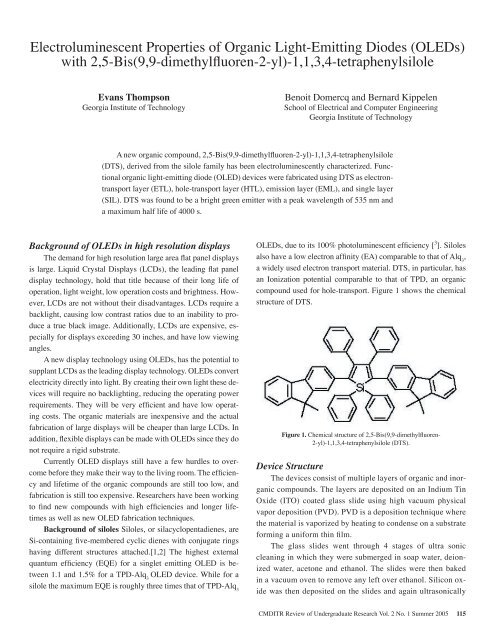

Electroluminescent Properties <strong>of</strong> Organic Light-Emitting Diodes (OLEDs)with 2,5-Bis(9,9-dimethylfluoren-2-yl)-1,1,3,4-tetraphenylsiloleEvans ThompsonGeorgia Institute <strong>of</strong> TechnologyBenoit Domercq and Bernard KippelenSchool <strong>of</strong> Electrical and Computer EngineeringGeorgia Institute <strong>of</strong> TechnologyA new organic compound, 2,5-Bis(9,9-dimethylfluoren-2-yl)-1,1,3,4-tetraphenylsilole(DTS), derived from the silole family has been electroluminescently characterized. Functionalorganic light-emitting diode (OLED) devices were fabricated using DTS as electrontransportlayer (ETL), hole-transport layer (HTL), emission layer (EML), and single layer(SIL). DTS was found to be a bright green emitter with a peak wavelength <strong>of</strong> 535 nm anda maximum half life <strong>of</strong> 4000 s.Background <strong>of</strong> OLEDs in high resolution displaysThe demand for high resolution large area flat panel displaysis large. Liquid Crystal Displays (LCDs), the leading flat paneldisplay technology, hold that title because <strong>of</strong> their long life <strong>of</strong>operation, light weight, low operation costs and brightness. However,LCDs are not without their disadvantages. LCDs require abacklight, causing low contrast ratios due to an inability to producea true black image. Additionally, LCDs are expensive, especiallyfor displays exceeding 30 inches, and have low viewingangles.A new display technology using OLEDs, has the potential tosupplant LCDs as the leading display technology. OLEDs convertelectricity directly into light. By creating their own light these deviceswill require no backlighting, reducing the operating powerrequirements. They will be very efficient and have low operatingcosts. The organic materials are inexpensive and the actualfabrication <strong>of</strong> large displays will be cheaper than large LCDs. Inaddition, flexible displays can be made with OLEDs since they donot require a rigid substrate.Currently OLED displays still have a few hurdles to overcomebefore they make their way to the living room. The efficiencyand lifetime <strong>of</strong> the organic compounds are still too low, andfabrication is still too expensive. Researchers have been workingto find new compounds with high efficiencies and longer lifetimesas well as new OLED fabrication techniques.Background <strong>of</strong> siloles Siloles, or silacyclopentadienes, areSi-containing five-membered cyclic dienes with conjugate ringshaving different structures attached.[1,2] The highest externalquantum efficiency (EQE) for a singlet emitting OLED is between1.1 and 1.5% for a TPD-Alq 3OLED device. While for asilole the maximum EQE is roughly three times that <strong>of</strong> TPD-Alq 3OLEDs, due to its 100% photoluminescent efficiency [ 3 ]. Silolesalso have a low electron affinity (EA) comparable to that <strong>of</strong> Alq 3,a widely used electron transport material. DTS, in particular, hasan Ionization potential comparable to that <strong>of</strong> TPD, an organiccompound used for hole-transport. Figure 1 shows the chemicalstructure <strong>of</strong> DTS.Figure 1. Chemical structure <strong>of</strong> 2,5-Bis(9,9-dimethylfluoren-2-yl)-1,1,3,4-tetraphenylsilole (DTS).Device StructureThe devices consist <strong>of</strong> multiple layers <strong>of</strong> organic and inorganiccompounds. The layers are deposited on an Indium TinOxide (ITO) coated glass slide using high vacuum physicalvapor deposition (PVD). PVD is a deposition technique wherethe material is vaporized by heating to condense on a substrateforming a uniform thin film.The glass slides went through 4 stages <strong>of</strong> ultra soniccleaning in which they were submerged in soap water, deionizedwater, acetone and ethanol. The slides were then bakedin a vacuum oven to remove any left over ethanol. Silicon oxidewas then deposited on the slides and again ultrasonicallyCMDITR Review <strong>of</strong> Undergraduate Research Vol. 2 No. 1 Summer <strong>2005</strong> 115