Student Project Abstracts 2005 - Pluto - University of Washington

Student Project Abstracts 2005 - Pluto - University of Washington

Student Project Abstracts 2005 - Pluto - University of Washington

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

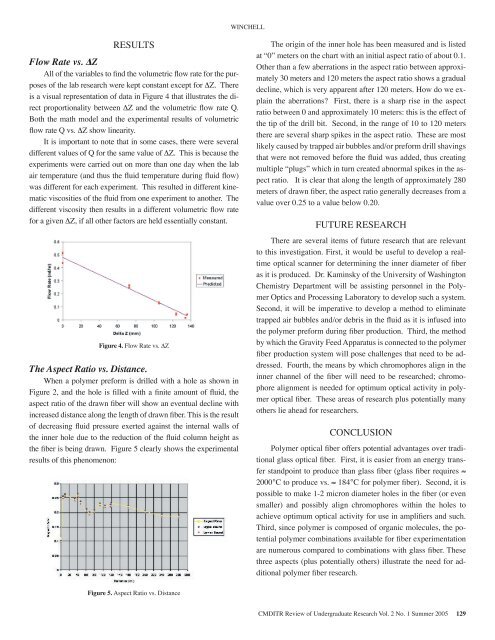

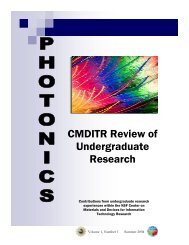

WINCHELLRESULTSFlow Rate vs. ∆ZAll <strong>of</strong> the variables to find the volumetric flow rate for the purposes<strong>of</strong> the lab research were kept constant except for ΔZ. Thereis a visual representation <strong>of</strong> data in Figure 4 that illustrates the directproportionality between ΔZ and the volumetric flow rate Q.Both the math model and the experimental results <strong>of</strong> volumetricflow rate Q vs. ΔZ show linearity.It is important to note that in some cases, there were severaldifferent values <strong>of</strong> Q for the same value <strong>of</strong> ΔZ. This is because theexperiments were carried out on more than one day when the labair temperature (and thus the fluid temperature during fluid flow)was different for each experiment. This resulted in different kinematicviscosities <strong>of</strong> the fluid from one experiment to another. Thedifferent viscosity then results in a different volumetric flow ratefor a given ΔZ, if all other factors are held essentially constant.Figure 4. Flow Rate vs. ΔZThe Aspect Ratio vs. Distance.When a polymer preform is drilled with a hole as shown inFigure 2, and the hole is filled with a finite amount <strong>of</strong> fluid, theaspect ratio <strong>of</strong> the drawn fiber will show an eventual decline withincreased distance along the length <strong>of</strong> drawn fiber. This is the result<strong>of</strong> decreasing fluid pressure exerted against the internal walls <strong>of</strong>the inner hole due to the reduction <strong>of</strong> the fluid column height asthe fiber is being drawn. Figure 5 clearly shows the experimentalresults <strong>of</strong> this phenomenon:The origin <strong>of</strong> the inner hole has been measured and is listedat “0” meters on the chart with an initial aspect ratio <strong>of</strong> about 0.1.Other than a few aberrations in the aspect ratio between approximately30 meters and 120 meters the aspect ratio shows a gradualdecline, which is very apparent after 120 meters. How do we explainthe aberrations? First, there is a sharp rise in the aspectratio between 0 and approximately 10 meters: this is the effect <strong>of</strong>the tip <strong>of</strong> the drill bit. Second, in the range <strong>of</strong> 10 to 120 metersthere are several sharp spikes in the aspect ratio. These are mostlikely caused by trapped air bubbles and/or preform drill shavingsthat were not removed before the fluid was added, thus creatingmultiple “plugs” which in turn created abnormal spikes in the aspectratio. It is clear that along the length <strong>of</strong> approximately 280meters <strong>of</strong> drawn fiber, the aspect ratio generally decreases from avalue over 0.25 to a value below 0.20.FUTURE RESEARCHThere are several items <strong>of</strong> future research that are relevantto this investigation. First, it would be useful to develop a realtimeoptical scanner for determining the inner diameter <strong>of</strong> fiberas it is produced. Dr. Kaminsky <strong>of</strong> the <strong>University</strong> <strong>of</strong> <strong>Washington</strong>Chemistry Department will be assisting personnel in the PolymerOptics and Processing Laboratory to develop such a system.Second, it will be imperative to develop a method to eliminatetrapped air bubbles and/or debris in the fluid as it is infused intothe polymer preform during fiber production. Third, the methodby which the Gravity Feed Apparatus is connected to the polymerfiber production system will pose challenges that need to be addressed.Fourth, the means by which chromophores align in theinner channel <strong>of</strong> the fiber will need to be researched; chromophorealignment is needed for optimum optical activity in polymeroptical fiber. These areas <strong>of</strong> research plus potentially manyothers lie ahead for researchers.CONCLUSIONPolymer optical fiber <strong>of</strong>fers potential advantages over traditionalglass optical fiber. First, it is easier from an energy transferstandpoint to produce than glass fiber (glass fiber requires ≈2000°C to produce vs. ≈ 184°C for polymer fiber). Second, it ispossible to make 1-2 micron diameter holes in the fiber (or evensmaller) and possibly align chromophores within the holes toachieve optimum optical activity for use in amplifiers and such.Third, since polymer is composed <strong>of</strong> organic molecules, the potentialpolymer combinations available for fiber experimentationare numerous compared to combinations with glass fiber. Thesethree aspects (plus potentially others) illustrate the need for additionalpolymer fiber research.Figure 5. Aspect Ratio vs. DistanceCMDITR Review <strong>of</strong> Undergraduate Research Vol. 2 No. 1 Summer <strong>2005</strong> 129