SYNTEC CNC Application manual - Winter Holztechnik

SYNTEC CNC Application manual - Winter Holztechnik

SYNTEC CNC Application manual - Winter Holztechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

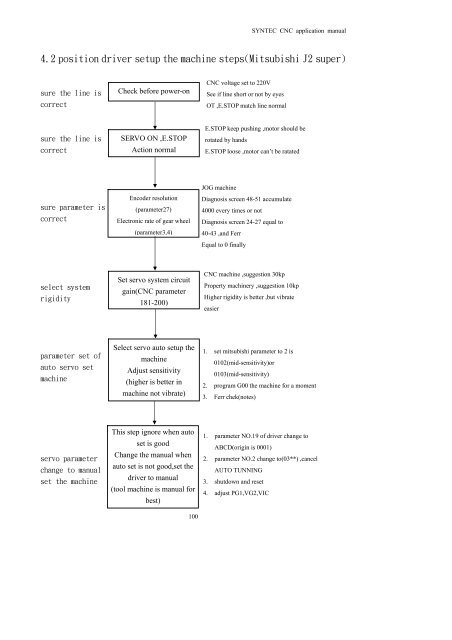

<strong>SYNTEC</strong> <strong>CNC</strong> application <strong>manual</strong>4.2 position driver setup the machine steps(Mitsubishi J2 super)sure the line iscorrectCheck before power-on<strong>CNC</strong> voltage set to 220VSee if line short or not by eyesOT ,E.STOP match line normalsure the line iscorrectSERVO ON ,E.STOPAction normalE.STOP keep pushing ,motor should berotated by handsE.STOP loose ,motor can’t be ratatedsure parameter iscorrectEncoder resolution(parameter27)Electronic rate of gear wheel(parameter3,4)JOG machineDiagnosis screen 48-51 accumulate4000 every times or notDiagnosis screen 24-27 equal to40-43 ,and FerrEqual to 0 finallyselect systemrigiditySet servo system circuitgain(<strong>CNC</strong> parameter181-200)<strong>CNC</strong> machine ,suggestion 30kpProperty machinery ,suggestion 10kpHigher rigidity is better ,but vibrateeasierparameter set ofauto servo setmachineSelect servo auto setup themachineAdjust sensitivity(higher is better inmachine not vibrate)1. set mitsubishi parameter to 2 is0102(mid-sensitivity)or0103(mid-sensitivity)2. program G00 the machine for a moment3. Ferr chek(notes)servo parameterchange to <strong>manual</strong>set the machineThis step ignore when autoset is goodChange the <strong>manual</strong> whenauto set is not good,set thedriver to <strong>manual</strong>(tool machine is <strong>manual</strong> forbest)1001. parameter NO.19 of driver change toABCD(origin is 0001)2. parameter NO.2 change to(03**) ,cancelAUTO TUNNING3. shutdown and reset4. adjust PG1,VG2,VIC