SYNTEC CNC Application manual - Winter Holztechnik

SYNTEC CNC Application manual - Winter Holztechnik

SYNTEC CNC Application manual - Winter Holztechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

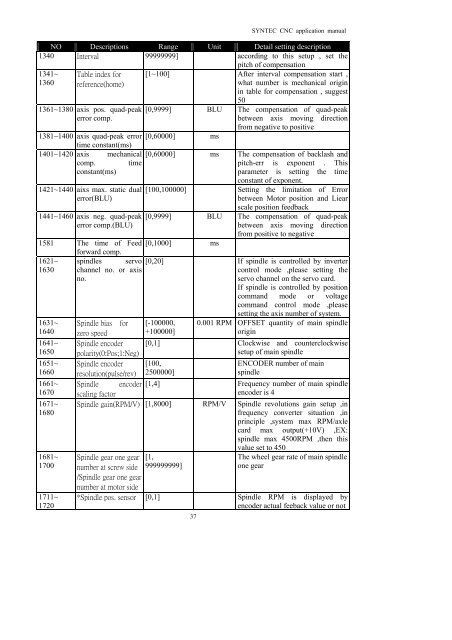

37<strong>SYNTEC</strong> <strong>CNC</strong> application <strong>manual</strong>NO Descriptions Range Unit Detail setting description1340 Interval 99999999] according to this setup , set thepitch of compensation1341~1360Table index forreference(home)1361~1380 axis pos. quad-peakerror comp.1381~1400 axis quad-peak error [0,60000] mstime constant(ms)1401~1420 axis mechanicalcomp. timeconstant(ms)1421~1440 aixs max. static dualerror(BLU)1441~1460 axis neg. quad-peakerror comp.(BLU)1581 The time of Feed [0,1000] msforward comp.1621~1630spindles servo1631~16401641~16501651~16601661~16701671~16801681~17001711~1720channel no. or axisno.[1~100] After interval compensation start ,what number is mechanical originin table for compensation , suggest50[0,9999] BLU The compensation of quad-peakbetween axis moving directionfrom negative to positive[0,60000] ms The compensation of backlash andpitch-err is exponent . Thisparameter is setting the timeconstant of exponent.[100,100000] Setting the limitation of Errorbetween Motor position and Liearscale position feedback[0,9999] BLU The compensation of quad-peakbetween axis moving directionfrom positive to negative[0,20] If spindle is controlled by invertercontrol mode ,please setting theservo channel on the servo card.If spindle is controlled by positioncommand mode or voltagecommand control mode ,pleasesetting the axis number of system.Spindle bias forzero speed[-100000,+100000]0.001 RPM OFFSET quantity of main spindleoriginSpindle encoder [0,1] Clockwise and counterclockwisepolarity(0:Pos;1:Neg)setup of main spindleSpindle encoder [100,ENCODER number of mainresolution(pulse/rev) 2500000]spindleSpindle encoder [1,4] Frequency number of main spindlescaling factorencoder is 4Spindle gain(RPM/V) [1,8000] RPM/V Spindle revolutions gain setup ,infrequency converter situation ,inprinciple ,system max RPM/axlecard max output(+10V) ,EX:spindle max 4500RPM ,then thisvalue set to 450Spindle gear one gearnumber at screw side/Spindle gear one gearnumber at motor side[1,999999999]The wheel gear rate of main spindleone gear*Spindle pos. sensor [0,1] Spindle RPM is displayed byencoder actual feeback value or not