SYNTEC CNC Application manual - Winter Holztechnik

SYNTEC CNC Application manual - Winter Holztechnik

SYNTEC CNC Application manual - Winter Holztechnik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

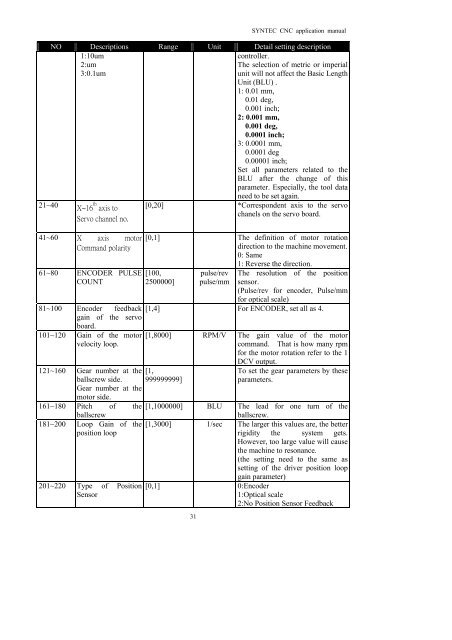

31<strong>SYNTEC</strong> <strong>CNC</strong> application <strong>manual</strong>NO Descriptions Range Unit Detail setting description1:10um2:um3:0.1umcontroller.The selection of metric or imperialunit will not affect the Basic LengthUnit (BLU) .1: 0.01 mm,0.01 deg,0.001 inch;2: 0.001 mm,0.001 deg,0.0001 inch;3: 0.0001 mm,0.0001 deg0.00001 inch;Set all parameters related to theBLU after the change of thisparameter. Especially, the tool data21~40 X~16 th axis toServo channel no.41~60 X axis motorCommand polarity61~80 ENCODER PULSECOUNT81~100 Encoder feedbackgain of the servoboard.101~120 Gain of the motorvelocity loop.121~160 Gear number at theballscrew side.Gear number at themotor side.need to be set again.[0,20] *Correspondent axis to the servochanels on the servo board.[0,1] The definition of motor rotationdirection to the machine movement.0: Same1: Reverse the direction.[100,2500000]pulse/revpulse/mmThe resolution of the positionsensor.(Pulse/rev for encoder, Pulse/mmfor optical scale)[1,4] For ENCODER, set all as 4.[1,8000] RPM/V The gain value of the motorcommand. That is how many rpmfor the motor rotation refer to the 1DCV output.[1,999999999]To set the gear parameters by theseparameters.161~180 Pitch of the [1,1000000] BLU The lead for one turn of theballscrewballscrew.181~200 Loop Gain of theposition loop201~220 Type of PositionSensor[1,3000] 1/sec The larger this values are, the betterrigidity the system gets.However, too large value will causethe machine to resonance.(the setting need to the same assetting of the driver position loopgain parameter)[0,1] 0:Encoder1:Optical scale2:No Position Sensor Feedback