Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

138<br />

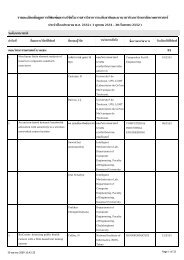

Determination of enzyme activities<br />

Carboxymethyl cellulase activity (CMcellulase)<br />

was detemined by the modified method<br />

of Okeke and Obi (1995) by performing the<br />

reaction mixture of 0.1 ml of sample and 0.1 ml<br />

of 1 % (w/v) CMC (Sigma) in 50 mM citrate<br />

phosphate buffer pH 5.5 at 50°C for 20 min. The<br />

amount of reducing sugar released was determined<br />

by Dinitrosalicylic acid (DNS) method (Miller,<br />

1959). One unit of enzyme was defined as the<br />

amount of enzyme that released glucose equivalent<br />

to 1 µmol of glucose per min.<br />

β-1,3-1,4-glucanase activity was<br />

measured using the same procedure as<br />

carboxymethyl cellulase activity. However, 1 %<br />

(w/v) of barley β-glucan (Sigma) was used as<br />

substrate. One unit of enzyme was defined as<br />

mentioned above<br />

Xylanase activity was measured by the<br />

same method described by the modified method<br />

of Okeke and Obi (1995), but 1% (w/v) of oat spelt<br />

xylan (Sigma) was used as substrate. One unit of<br />

enzyme was defined as mentioned above.<br />

Pectin methylesterase activitiy was<br />

measured using the modification method of Huang<br />

and Mahomey (1999) by titration of carboxyl<br />

groups released from pectin (Sigma) at 50°C for<br />

20 min. Approximately 0.5 ml of enzyme sample<br />

was mixed with 4.5 ml of 0.5% pectin in 50 mM<br />

cirtrate phosphate buffer pH 5.5. The acid released<br />

was titrated with 0.01 N NaOH. One unit of pectin<br />

methylesterase was defined as the amount of<br />

enzyme which released 1 mmole of carboxyl<br />

groups per min under the assay condition.<br />

Pectin lyase activitiy was determined<br />

according to the modification method of Huang<br />

and Mahomey (1999). 0.1 ml enzyme sample was<br />

mixed with 0.4 ml of 0.5 % pectin in 50mM cirtrate<br />

phosphate buffer pH 5.5, incubated at 50°C for 20<br />

min. 4 ml of 0.01 M HCl was added and<br />

absorbance was measured at 235 nm. One unit of<br />

pectin lyase was defined as the amount of enzyme<br />

which released 4-5 unsaturated trans-elimination<br />

Kasetsart J. (Nat. Sci.) 40(1)<br />

products showing absorbance of 0.2 at 235 nm.<br />

Pectate lyase activitiy was determined by<br />

the same method of pectin lyase activity<br />

determination, except that 0.5% polygalacturonic<br />

acid (PGA) (Sigma) was used as substrate. One<br />

unit of pectate lyase was defined as the amount of<br />

enzyme which released unsaturated transelimination<br />

products showing absorbance of 0.2<br />

at 235 nm.<br />

Polygalacturonase activity was measured<br />

by the method of pectate lyase activity assay as<br />

mensioned above, except that 1% pectin was used<br />

as a substrate. One unit of enzyme was defined as<br />

the amount of enzyme that released galactose<br />

equivalent to 1 µmol of galacturonic acid per min.<br />

Polymethylgalacturonase activity was<br />

measured by the method of carboxymethyl<br />

cellulase activity assay mensioned elsewhere,<br />

except that 1% PGA was used as substrate. One<br />

unit of enzyme was defined as the amount of<br />

enzyme that released reducing sugar equivalent<br />

to 1 µmol of galacturonic acid per min.<br />

Protein assay<br />

Protein concentration was determined by<br />

the method of Lowry et al. (1951) using bovine<br />

serum albumin as a standard.<br />

Determination of grass degradation activity<br />

Cell-free culture fluid (CFC) containing<br />

enzyme components was filtrated with 0.2 micron<br />

filter membrane. One ml of CFC was added to the<br />

tube containing 1 g of grass powder prepared by<br />

milling and sieving (mesh number 120). The<br />

mixture was incubated for 24 h at experimental<br />

temperatures. Then the extract solution was<br />

prepared using the method of Ohmomo et al.<br />

(1995). In brief, 10 ml of distilled water was added<br />

into the reaction mixture, shaked at 100 rpm for 2<br />

h and then filtrated through Whatman No.4 paper<br />

filter. To remove all residual soluble carbohydrates,<br />

the retentate was washed with 10 ml distilled water<br />

twice. All filtrates were pooled and adjusted to the