VGB POWERTECH 7 (2020) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2020). Technical Journal of the VGB PowerTech Association. Energy is us! Maintenance. Thermal waste utilisation

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2020).

Technical Journal of the VGB PowerTech Association. Energy is us!

Maintenance. Thermal waste utilisation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical risk management <strong>of</strong> hydropower plants <strong>VGB</strong> PowerTech 7 l <strong>2020</strong><br />

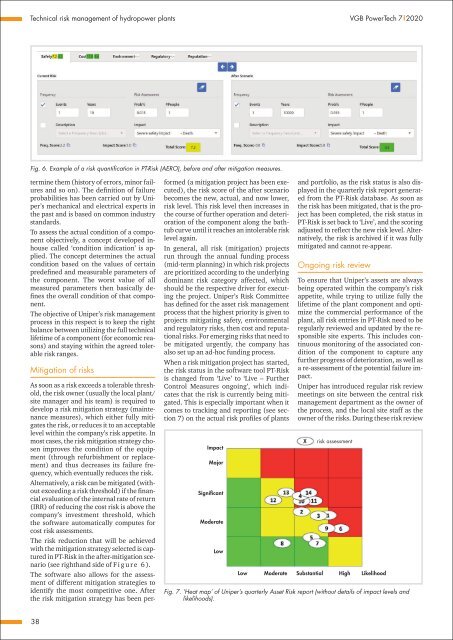

Fig. 6. Example <strong>of</strong> a risk quantification in PT-Risk (AERO), be<strong>for</strong>e <strong>and</strong> after mitigation measures.<br />

termine them (history <strong>of</strong> errors, minor failures<br />

<strong>and</strong> so on). The definition <strong>of</strong> failure<br />

probabilities has been carried out by Uniper’s<br />

mechanical <strong>and</strong> electrical experts in<br />

the past <strong>and</strong> is based on common industry<br />

st<strong>and</strong>ards.<br />

To assess the actual condition <strong>of</strong> a component<br />

objectively, a concept developed inhouse<br />

called ‘condition indication’ is applied.<br />

The concept determines the actual<br />

condition based on the values <strong>of</strong> certain<br />

predefined <strong>and</strong> measurable parameters <strong>of</strong><br />

the component. The worst value <strong>of</strong> all<br />

measured parameters then basically defines<br />

the overall condition <strong>of</strong> that component.<br />

The objective <strong>of</strong> Uniper’s risk management<br />

process in this respect is to keep the right<br />

balance between utilizing the full technical<br />

lifetime <strong>of</strong> a component (<strong>for</strong> economic reasons)<br />

<strong>and</strong> staying within the agreed tolerable<br />

risk ranges.<br />

Mitigation <strong>of</strong> risks<br />

As soon as a risk exceeds a tolerable threshold,<br />

the risk owner (usually the local plant/<br />

site manager <strong>and</strong> his team) is required to<br />

develop a risk mitigation strategy (maintenance<br />

measures), which either fully mitigates<br />

the risk, or reduces it to an acceptable<br />

level within the company’s risk appetite. In<br />

most cases, the risk mitigation strategy chosen<br />

improves the condition <strong>of</strong> the equipment<br />

(through refurbishment or replacement)<br />

<strong>and</strong> thus decreases its failure frequency,<br />

which eventually reduces the risk.<br />

Alternatively, a risk can be mitigated (without<br />

exceeding a risk threshold) if the financial<br />

evaluation <strong>of</strong> the internal rate <strong>of</strong> return<br />

(IRR) <strong>of</strong> reducing the cost risk is above the<br />

company’s investment threshold, which<br />

the s<strong>of</strong>tware automatically computes <strong>for</strong><br />

cost risk assessments.<br />

The risk reduction that will be achieved<br />

with the mitigation strategy selected is captured<br />

in PT-Risk in the after-mitigation scenario<br />

(see righth<strong>and</strong> side <strong>of</strong> F i g u r e 6 ).<br />

The s<strong>of</strong>tware also allows <strong>for</strong> the assessment<br />

<strong>of</strong> different mitigation strategies to<br />

identify the most competitive one. After<br />

the risk mitigation strategy has been per<strong>for</strong>med<br />

(a mitigation project has been executed),<br />

the risk score <strong>of</strong> the after scenario<br />

becomes the new, actual, <strong>and</strong> now lower,<br />

risk level. This risk level then increases in<br />

the course <strong>of</strong> further operation <strong>and</strong> deterioration<br />

<strong>of</strong> the component along the bathtub<br />

curve until it reaches an intolerable risk<br />

level again.<br />

In general, all risk (mitigation) projects<br />

run through the annual funding process<br />

(mid-term planning) in which risk projects<br />

are prioritized according to the underlying<br />

dominant risk category affected, which<br />

should be the respective driver <strong>for</strong> executing<br />

the project. Uniper’s Risk Committee<br />

has defined <strong>for</strong> the asset risk management<br />

process that the highest priority is given to<br />

projects mitigating safety, environmental<br />

<strong>and</strong> regulatory risks, then cost <strong>and</strong> reputational<br />

risks. For emerging risks that need to<br />

be mitigated urgently, the company has<br />

also set up an ad-hoc funding process.<br />

When a risk mitigation project has started,<br />

the risk status in the s<strong>of</strong>tware tool PT-Risk<br />

is changed from ‘Live’ to ‘Live – Further<br />

Control Measures ongoing’, which indicates<br />

that the risk is currently being mitigated.<br />

This is especially important when it<br />

comes to tracking <strong>and</strong> reporting (see section<br />

7) on the actual risk pr<strong>of</strong>iles <strong>of</strong> plants<br />

Impact<br />

Major<br />

Significant<br />

Moderate<br />

Low<br />

<strong>and</strong> portfolio, as the risk status is also displayed<br />

in the quarterly risk report generated<br />

from the PT-Risk database. As soon as<br />

the risk has been mitigated, that is the project<br />

has been completed, the risk status in<br />

PT-Risk is set back to ‘Live’, <strong>and</strong> the scoring<br />

adjusted to reflect the new risk level. Alternatively,<br />

the risk is archived if it was fully<br />

mitigated <strong>and</strong> cannot re-appear.<br />

Ongoing risk review<br />

To ensure that Uniper’s assets are always<br />

being operated within the company’s risk<br />

appetite, while trying to utilize fully the<br />

lifetime <strong>of</strong> the plant component <strong>and</strong> optimize<br />

the commercial per<strong>for</strong>mance <strong>of</strong> the<br />

plant, all risk entries in PT-Risk need to be<br />

regularly reviewed <strong>and</strong> updated by the responsible<br />

site experts. This includes continuous<br />

monitoring <strong>of</strong> the associated condition<br />

<strong>of</strong> the component to capture any<br />

further progress <strong>of</strong> deterioration, as well as<br />

a re-assessment <strong>of</strong> the potential failure impact.<br />

Uniper has introduced regular risk review<br />

meetings on site between the central risk<br />

management department as the owner <strong>of</strong><br />

the process, <strong>and</strong> the local site staff as the<br />

owner <strong>of</strong> the risks. During these risk review<br />

risk assessment<br />

Low Moderate Substantial High Likelihood<br />

Fig. 7. ‘<strong>Heat</strong> map’ <strong>of</strong> Uniper’s quarterly Asset Risk report (without details <strong>of</strong> impact levels <strong>and</strong><br />

likelihoods).<br />

X<br />

38