VGB POWERTECH 7 (2020) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2020). Technical Journal of the VGB PowerTech Association. Energy is us! Maintenance. Thermal waste utilisation

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2020).

Technical Journal of the VGB PowerTech Association. Energy is us!

Maintenance. Thermal waste utilisation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The Bi<strong>of</strong>ficiency Project | Part 1 <strong>VGB</strong> PowerTech 7 l <strong>2020</strong><br />

Tab. 5. Overview on biomass ashes selected <strong>for</strong> Bi<strong>of</strong>ficiency.<br />

Full-scale unit Capacity / MW el Biomass fuel Combustion<br />

system<br />

Rodenhuize<br />

150 MW<br />

Wood pellets 1<br />

Wood pellets 2<br />

Wood pellets 3<br />

Wood pellets 4<br />

<strong>of</strong> different techniques is important. For<br />

example, with XRF analyses, the presence<br />

<strong>of</strong> carbonate, hydrate, hydroxide <strong>and</strong> UBC<br />

must be taken into account.<br />

There may be some differences in the ashes<br />

produced in laboratory-, bench-, pilot-, <strong>and</strong><br />

full-scale boilers. In small scale, the fuel<br />

can be more homogeneous than in fullscale,<br />

which consumes several truckloads<br />

<strong>of</strong> biomass per hour. On the other h<strong>and</strong>, the<br />

fly ash from the pilot-scale combustors may<br />

contain significant amounts <strong>of</strong> stainless<br />

steel corrosion products such as Cr <strong>and</strong> Ni.<br />

At full-scale plants, the biomass fuels are<br />

combusted at temperatures about between<br />

850 °C <strong>and</strong> 1,500 °C depending on the combustion<br />

technology, <strong>and</strong> include processes<br />

<strong>of</strong> evaporation <strong>and</strong> condensation <strong>of</strong> compounds<br />

<strong>of</strong> Na, K, Cl, S, P, etc. Evaporation<br />

occurs at the high combustion temperatures<br />

<strong>and</strong> condensation upon cooling <strong>of</strong> the<br />

flue gases. At higher combustion temperatures,<br />

there is more evaporation <strong>of</strong> K, Na,<br />

Cl, S, P, which condensate on the ashes<br />

upon cooling <strong>of</strong> the flue gases, <strong>and</strong> hence<br />

more salts are present in the fly ash.<br />

Fly ashes produced at higher combustion<br />

temperatures (PF) differ markedly from<br />

those produced at lower combustion temperatures<br />

(CFB), not only regarding salt<br />

content, but also, regarding reactivity at<br />

temperatures above 850 °C. This was demonstrated<br />

by TGA/DTA/DSC analyses,<br />

which show exothermic reactions with<br />

CFBC fly ashes at temperatures above 850 °C.<br />

Problematic components regarding exact<br />

<strong>and</strong> repeatable analysis are <strong>of</strong>ten B, Cl<br />

<strong>and</strong> F, which require further attention.<br />

Additives<br />

Avedøre 2 400 MW Wood pellets PF Bituminous coal fly ash<br />

Herning 78 MW Wood chips Grate none<br />

Pulp&paper mill<br />

power plant<br />

PF<br />

none<br />

none<br />

none<br />

none<br />

87 MW Bark CFB none<br />

Pilot-scale unit Fuel input / kW th Biomass fuel<br />

Valmet pilot plant<br />

VTT pilot plant<br />

TUM pilot plant<br />

4000 kW<br />

50 kW<br />

200 kW<br />

Bark<br />

EFB<br />

EFB <strong>and</strong> coal<br />

Bark<br />

Torrewashed bark<br />

Torrewashed bark<br />

Torrewashed straw<br />

Straw<br />

Bark<br />

SE bark<br />

SE bark<br />

Combustion<br />

system<br />

CFB<br />

CFB<br />

PF<br />

Additives<br />

none<br />

none<br />

none<br />

none<br />

none<br />

Sulphur<br />

Kaolin<br />

Kaolin<br />

none<br />

Kaolin<br />

Coal fly ash<br />

With increasing combustion temperature,<br />

more Cr(VI) is anticipated. This is critical,<br />

since Cr(VI) is known to be carcinogenic<br />

<strong>and</strong> toxic. Consequently, more work on the<br />

aspect <strong>of</strong> Cr(VI) in ash is required.<br />

By water-leaching <strong>of</strong> the biomass fuel i.e. in<br />

pre-treatment, fly ashes will contain less<br />

Na, K, Cl <strong>and</strong> S, <strong>and</strong> hence less salts will be<br />

present in the fly ashes.<br />

2.4.2 Novel applications <strong>for</strong> biomass ash<br />

In the course <strong>of</strong> the project existing valorisation<br />

options <strong>for</strong> biomass ashes such as<br />

use as fertiliser, filler materials or construction<br />

materials were identified.<br />

However, many <strong>of</strong> these applications can<br />

be considered as “creative” l<strong>and</strong> filling, at<br />

least by authorities <strong>and</strong> NGOs. Some <strong>of</strong><br />

these applications are not specific <strong>for</strong> biomass<br />

ash. New potential applications were<br />

identified that exlude applications including<br />

l<strong>and</strong> filling <strong>and</strong> applications that are<br />

not specific <strong>for</strong> biomass ash.<br />

––<br />

Leaching, with recovery <strong>of</strong> valuable elements<br />

<strong>and</strong> compounds, especially P <strong>and</strong> K<br />

––<br />

Application in traditional ceramics <strong>and</strong><br />

traditional glass<br />

––<br />

Application in geo-polymers<br />

––<br />

Recycling elements back to the soil, <strong>for</strong><br />

limiting depletion<br />

––<br />

Application as or in fertiliser<br />

––<br />

Application in calcium silicate bricks<br />

In the project these proposed valorisation<br />

options were evaluated. Due to the new EU<br />

fertiliser regulation 2019, the application<br />

<strong>of</strong> biomass ashes in top-soils seems to be<br />

restricted. Biomass ashes will most probably<br />

exceed limits <strong>for</strong> allowed concentrations<br />

<strong>of</strong> toxic heavy metals.<br />

On the other h<strong>and</strong>, the use <strong>of</strong> biomass ash<br />

in construction materials seems promising,<br />

especially in calcium silicate blocks <strong>and</strong><br />

geo-polymers. To achieve a higher added<br />

value in this field <strong>of</strong> application, biomass<br />

ash should be used as binder rather than as<br />

filler material. It could potentially replace<br />

limestone, which is currently mined <strong>and</strong><br />

calcined with high fossil CO 2 emissions.<br />

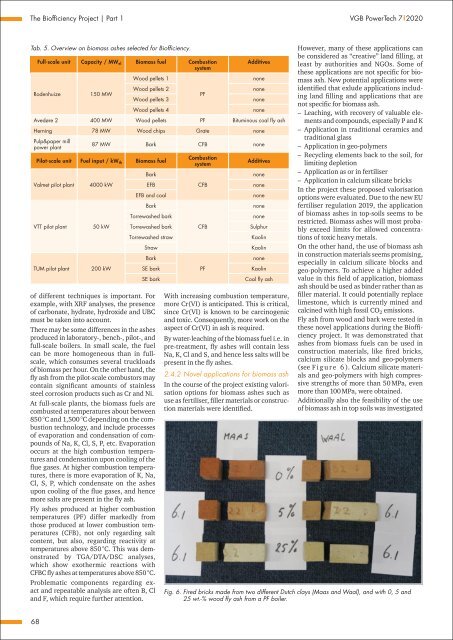

Fly ash from wood <strong>and</strong> bark were tested in<br />

these novel applications during the Bi<strong>of</strong>ficiency<br />

project. It was demonstrated that<br />

ashes from biomass fuels can be used in<br />

construction materials, like fired bricks,<br />

calcium silicate blocks <strong>and</strong> geo-polymers<br />

(see F i g u r e 6 ). Calcium silicate materials<br />

<strong>and</strong> geo-polymers with high compressive<br />

strengths <strong>of</strong> more than 50 MPa, even<br />

more than 100 MPa, were obtained.<br />

Additionally also the feasibility <strong>of</strong> the use<br />

<strong>of</strong> biomass ash in top soils was investigated<br />

Fig. 6. Fired bricks made from two different Dutch clays (Maas <strong>and</strong> Waal), <strong>and</strong> with 0, 5 <strong>and</strong><br />

25 wt.-% wood fly ash from a PF boiler.<br />

68