VGB POWERTECH 7 (2020) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2020). Technical Journal of the VGB PowerTech Association. Energy is us! Maintenance. Thermal waste utilisation

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2020).

Technical Journal of the VGB PowerTech Association. Energy is us!

Maintenance. Thermal waste utilisation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>VGB</strong> PowerTech 7 l <strong>2020</strong> The Bi<strong>of</strong>ficiency Project | Part 1<br />

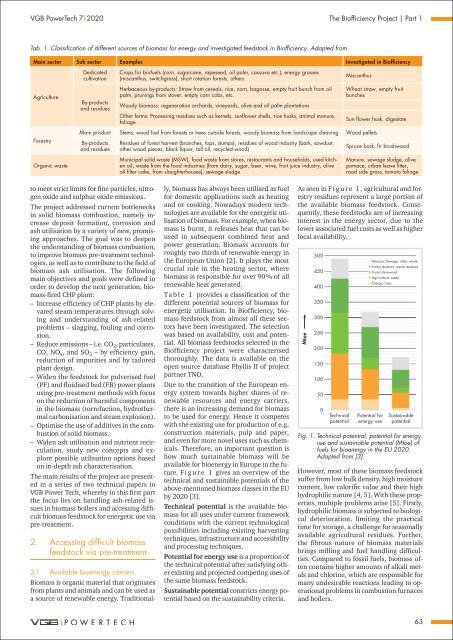

Tab. 1. Classification <strong>of</strong> different sources <strong>of</strong> biomass <strong>for</strong> energy <strong>and</strong> investigated feedstock in Bi<strong>of</strong>ficiency. Adapted from<br />

Main sector Sub sector Examples Investigated in Bi<strong>of</strong>ficiency<br />

Agriculture<br />

Forestry<br />

Organic waste<br />

Dedicated<br />

cultivation<br />

By-products<br />

<strong>and</strong> residues<br />

Crops <strong>for</strong> bi<strong>of</strong>uels (corn, sugarcane, rapeseed, oil palm, cassava etc.), energy grasses<br />

(miscanthus, switchgrass), short rotation <strong>for</strong>ests, others<br />

Herbaceous by-products: Straw from cereals, rice, corn, bagasse, empty fruit bunch from oil<br />

palm, prunings from stover, empty corn cobs, etc.<br />

Woody biomass: regeneration orchards, vineyards, olive <strong>and</strong> oil palm plantations<br />

Other <strong>for</strong>ms: Processing residues such as kernels, sunflower shells, rice husks, animal manure,<br />

foliage<br />

Miscanthus<br />

Wheat straw, empty fruit<br />

bunches<br />

Sun flower husk, digestate<br />

Main product Stems, wood fuel from <strong>for</strong>ests or trees outside <strong>for</strong>ests, woody biomass from l<strong>and</strong>scape cleaning Wood pellets<br />

By-products<br />

<strong>and</strong> residues<br />

Residues <strong>of</strong> <strong>for</strong>est harvest (branches, tops, stumps), residues <strong>of</strong> wood industry (bark, sawdust,<br />

other wood pieces, black liquor, tall oil, recycled wood)<br />

Municipal solid waste (MSW), food waste from stores, restaurants <strong>and</strong> households, used kitchen<br />

oil, waste from the food industries (from dairy, sugar, beer, wine, fruit juice industry, olive<br />

oil filter cake, from slaughterhouses), sewage sludge<br />

Spruce bark, fir brushwood<br />

Manure, sewage sludge, olive<br />

pomace, urban leave litter,<br />

road side grass, tomato foliage<br />

to meet strict limits <strong>for</strong> fine particles, nitrogen<br />

oxide <strong>and</strong> sulphur oxide emissions.<br />

The project addressed current bottlenecks<br />

in solid biomass combustion, namely increase<br />

deposit <strong>for</strong>mation, corrosion <strong>and</strong><br />

ash utilisation by a variety <strong>of</strong> new, promising<br />

approaches. The goal was to deepen<br />

the underst<strong>and</strong>ing <strong>of</strong> biomass combustion,<br />

to improve biomass pre-treatment technologies,<br />

as well as to contribute to the field <strong>of</strong><br />

biomass ash utilisation. The following<br />

main objectives <strong>and</strong> goals were defined in<br />

order to develop the next generation, biomass-fired<br />

CHP plant:<br />

––<br />

Increase efficiency <strong>of</strong> CHP plants by elevated<br />

steam temperatures through solving<br />

<strong>and</strong> underst<strong>and</strong>ing <strong>of</strong> ash-related<br />

problems – slagging, fouling <strong>and</strong> corrosion.<br />

––<br />

Reduce emissions – i.e. CO 2 , particulates,<br />

CO, NO x , <strong>and</strong> SO 2 – by efficiency gain,<br />

reduction <strong>of</strong> impurities <strong>and</strong> by tailored<br />

plant design.<br />

––<br />

Widen the feedstock <strong>for</strong> pulverised fuel<br />

(PF) <strong>and</strong> fluidised bed (FB) power plants<br />

using pre-treatment methods with focus<br />

on the reduction <strong>of</strong> harmful components<br />

in the biomass (torrefaction, hydrothermal<br />

carbonisation <strong>and</strong> steam explosion).<br />

––<br />

Optimise the use <strong>of</strong> additives in the combustion<br />

<strong>of</strong> solid biomass.<br />

––<br />

Widen ash utilisation <strong>and</strong> nutrient recirculation,<br />

study new concepts <strong>and</strong> explore<br />

possible utilisation options based<br />

on in-depth ash characterisation.<br />

The main results <strong>of</strong> the project are presented<br />

in a series <strong>of</strong> two technical papers in<br />

<strong>VGB</strong> Power Tech, whereby in this first part<br />

the focus lies on h<strong>and</strong>ling ash-related issues<br />

in biomass boilers <strong>and</strong> accessing difficult<br />

biomass feedstock <strong>for</strong> energetic use via<br />

pre-treatment.<br />

2. Accessing difficult biomass<br />

feedstock via pre-treatment<br />

2.1 Available bioenergy carriers<br />

Biomass is organic material that originates<br />

from plants <strong>and</strong> animals <strong>and</strong> can be used as<br />

a source <strong>of</strong> renewable energy. Traditionally,<br />

biomass has always been utilised as fuel<br />

<strong>for</strong> domestic applications such as heating<br />

<strong>and</strong> or cooking. Nowadays modern technologies<br />

are available <strong>for</strong> the energetic utilisation<br />

<strong>of</strong> biomass. For example, when biomass<br />

is burnt, it releases heat that can be<br />

used in subsequent combined heat <strong>and</strong><br />

power generation. Biomass accounts <strong>for</strong><br />

roughly two thirds <strong>of</strong> renewable energy in<br />

the European Union [2]. It plays the most<br />

crucial role in the heating sector, where<br />

biomass is responsible <strong>for</strong> over 90 % <strong>of</strong> all<br />

renewable heat generated.<br />

Ta b l e 1 provides a classification <strong>of</strong> the<br />

different potential sources <strong>of</strong> biomass <strong>for</strong><br />

energetic utilisation. In Bi<strong>of</strong>ficiency, biomass<br />

feedstock from almost all these sectors<br />

have been investigated. The selection<br />

was based on availability, cost <strong>and</strong> potential.<br />

All biomass feedstocks selected in the<br />

Bi<strong>of</strong>ficiency project were characterised<br />

thoroughly. The data is available on the<br />

open source database Phyllis II <strong>of</strong> project<br />

partner TNO.<br />

Due to the transition <strong>of</strong> the European energy<br />

system towards higher shares <strong>of</strong> renewable<br />

resources <strong>and</strong> energy carriers,<br />

there is an increasing dem<strong>and</strong> <strong>for</strong> biomass<br />

to be used <strong>for</strong> energy. Hence it competes<br />

with the existing use <strong>for</strong> production <strong>of</strong> e.g.<br />

construction materials, pulp <strong>and</strong> paper,<br />

<strong>and</strong> even <strong>for</strong> more novel uses such as chemicals.<br />

There<strong>for</strong>e, an important question is<br />

how much sustainable biomass will be<br />

available <strong>for</strong> bioenergy in Europe in the future.<br />

F i g u r e 1 gives an overview <strong>of</strong> the<br />

technical <strong>and</strong> sustainable potentials <strong>of</strong> the<br />

above-mentioned biomass classes in the EU<br />

by <strong>2020</strong> [3].<br />

Technical potential is the available biomass<br />

<strong>for</strong> all uses under current framework<br />

conditions with the current technological<br />

possibilities including existing harvesting<br />

techniques, infrastructure <strong>and</strong> accessibility<br />

<strong>and</strong> processing techniques.<br />

Potential <strong>for</strong> energy use is a proportion <strong>of</strong><br />

the technical potential after satisfying other<br />

existing <strong>and</strong> projected competing uses <strong>of</strong><br />

the same biomass feedstock.<br />

Sustainable potential constricts energy potential<br />

based on the sustainability criteria.<br />

As seen in F i g u r e 1 , agricultural <strong>and</strong> <strong>for</strong>estry<br />

residues represent a large portion <strong>of</strong><br />

the available biomass feedstock. Consequently,<br />

these feedstocks are <strong>of</strong> increasing<br />

interest in the energy sector, due to the<br />

lower associated fuel costs as well as higher<br />

local availability.<br />

Mtoe<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Technical<br />

potential<br />

Potential <strong>for</strong><br />

energy use<br />

Manure, Sewage, other waste<br />

Forest residues, wood residues<br />

Forest stemwood<br />

Agricultural waste<br />

Energy crops<br />

Sustainable<br />

potential<br />

Fig. 1. Technical potential, potential <strong>for</strong> energy<br />

use <strong>and</strong> sustainable potential (Mtoe) <strong>of</strong><br />

fuels <strong>for</strong> bioenergy in the EU <strong>2020</strong>.<br />

Adapted from [3].<br />

However, most <strong>of</strong> these biomass feedstock<br />

suffer from low bulk density, high moisture<br />

content, low calorific value <strong>and</strong> their high<br />

hydrophilic nature [4, 5]. With these properties,<br />

multiple problems arise [5]. Firstly,<br />

hydrophilic biomass is subjected to biological<br />

deterioration, limiting the practical<br />

time <strong>for</strong> storage, a challenge <strong>for</strong> seasonally<br />

available agricultural residues. Further,<br />

the fibrous nature <strong>of</strong> biomass materials<br />

brings milling <strong>and</strong> fuel h<strong>and</strong>ling difficulties.<br />

Compared to fossil fuels, biomass <strong>of</strong>ten<br />

contains higher amounts <strong>of</strong> alkali metals<br />

<strong>and</strong> chlorine, which are responsible <strong>for</strong><br />

many undesirable reactions leading to operational<br />

problems in combustion furnaces<br />

<strong>and</strong> boilers.<br />

63