VGB POWERTECH 7 (2020) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2020). Technical Journal of the VGB PowerTech Association. Energy is us! Maintenance. Thermal waste utilisation

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2020).

Technical Journal of the VGB PowerTech Association. Energy is us!

Maintenance. Thermal waste utilisation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A journey through 100 years <strong>VGB</strong> | Hydropower | <strong>VGB</strong> <strong>POWERTECH</strong> · Issue 10 (2006)<br />

Hydro-power in Europe<br />

New<br />

flap gate<br />

Existing<br />

gates<br />

Usual, confined water path<br />

New, multiple water path<br />

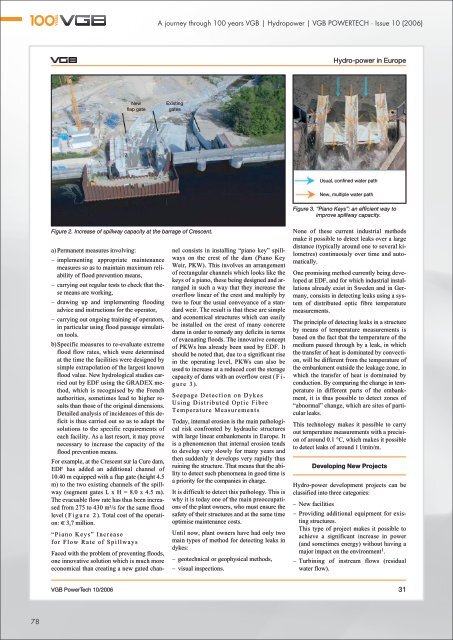

Figure 3. “Piano Keys”: an efficient way to<br />

improve spillway capacity.<br />

Figure 2. Increase <strong>of</strong> spillway capacity at the barrage <strong>of</strong> Crescent.<br />

a) Permanent measures involving:<br />

– implementing appropriate maintenance<br />

measures so as to maintain maximum reliability<br />

<strong>of</strong> flood prevention means,<br />

– carrying out regular tests to check that these<br />

means are working,<br />

– drawing up <strong>and</strong> implementing flooding<br />

advice <strong>and</strong> instructions <strong>for</strong> the operator,<br />

– carrying out ongoing training <strong>of</strong> operators,<br />

in particular using flood passage simulation<br />

tools.<br />

b)Specific measures to re-evaluate extreme<br />

flood flow rates, which were determined<br />

at the time the facilities were designed by<br />

simple extrapolation <strong>of</strong> the largest known<br />

flood value. New hydrological studies carried<br />

out by EDF using the GRADEX method,<br />

which is recognised by the French<br />

authorities, sometimes lead to higher results<br />

than those <strong>of</strong> the original dimensions.<br />

Detailed analysis <strong>of</strong> incidences <strong>of</strong> this deficit<br />

is thus carried out so as to adapt the<br />

solutions to the specific requirements <strong>of</strong><br />

each facility. As a last resort, it may prove<br />

necessary to increase the capacity <strong>of</strong> the<br />

flood prevention means.<br />

For example, at the Crescent sur la Cure dam,<br />

EDF has added an additional channel <strong>of</strong><br />

10.40 m equipped with a flap gate (height 4.5<br />

m) to the two existing channels <strong>of</strong> the spillway<br />

(segment gates L x H = 8.0 x 4.5 m).<br />

The evacuable flow rate has thus been increased<br />

from 275 to 430 m 3 /s <strong>for</strong> the same flood<br />

level ( F i gure 2). Total cost <strong>of</strong> the operation:<br />

€ 3,7 million.<br />

“Piano Keys” Increase<br />

<strong>for</strong> Flow Rate <strong>of</strong> Spillways<br />

Faced with the problem <strong>of</strong> preventing floods,<br />

one innovative solution which is much more<br />

economical than creating a new gated channel<br />

consists in installing “piano key” spillways<br />

on the crest <strong>of</strong> the dam (Piano Key<br />

Weir, PKW). This involves an arrangement<br />

<strong>of</strong> rectangular channels which looks like the<br />

keys <strong>of</strong> a piano, these being designed <strong>and</strong> arranged<br />

in such a way that they increase the<br />

overflow linear <strong>of</strong> the crest <strong>and</strong> multiply by<br />

two to four the usual conveyance <strong>of</strong> a st<strong>and</strong>ard<br />

weir. The result is that these are simple<br />

<strong>and</strong> economical structures which can easily<br />

be installed on the crest <strong>of</strong> many concrete<br />

dams in order to remedy any deficits in terms<br />

<strong>of</strong> evacuating floods. The innovative concept<br />

<strong>of</strong> PKWs has already been used by EDF. It<br />

should be noted that, due to a significant rise<br />

in the operating level, PKWs can also be<br />

used to increase at a reduced cost the storage<br />

capacity <strong>of</strong> dams with an overflow crest ( F i -<br />

gure 3).<br />

Seepage Detection on Dykes<br />

Using Distributed Optic Fibre<br />

Temperature Measurements<br />

Today, internal erosion is the main pathological<br />

risk confronted by hydraulic structures<br />

with large linear embankments in Europe. It<br />

is a phenomenon that internal erosion tends<br />

to develop very slowly <strong>for</strong> many years <strong>and</strong><br />

then suddenly it develops very rapidly thus<br />

ruining the structure. That means that the ability<br />

to detect such phenomena in good time is<br />

a priority <strong>for</strong> the companies in charge.<br />

It is difficult to detect this pathology. This is<br />

why it is today one <strong>of</strong> the main preoccupations<br />

<strong>of</strong> the plant owners, who must ensure the<br />

safety <strong>of</strong> their structures <strong>and</strong> at the same time<br />

optimise maintenance costs.<br />

Until now, plant owners have had only two<br />

main types <strong>of</strong> method <strong>for</strong> detecting leaks in<br />

dykes:<br />

– geotechnical or geophysical methods,<br />

– visual inspections.<br />

None <strong>of</strong> these current industrial methods<br />

make it possible to detect leaks over a large<br />

distance (typically around one to several kilometres)<br />

continuously over time <strong>and</strong> automatically.<br />

One promising method currently being developed<br />

at EDF, <strong>and</strong> <strong>for</strong> which industrial installations<br />

already exist in Sweden <strong>and</strong> in Germany,<br />

consists in detecting leaks using a system<br />

<strong>of</strong> distributed optic fibre temperature<br />

measurements.<br />

The principle <strong>of</strong> detecting leaks in a structure<br />

by means <strong>of</strong> temperature measurements is<br />

based on the fact that the temperature <strong>of</strong> the<br />

medium passed through by a leak, in which<br />

the transfer <strong>of</strong> heat is dominated by convection,<br />

will be different from the temperature <strong>of</strong><br />

the embankment outside the leakage zone, in<br />

which the transfer <strong>of</strong> heat is dominated by<br />

conduction. By comparing the change in temperature<br />

in different parts <strong>of</strong> the embankment,<br />

it is thus possible to detect zones <strong>of</strong><br />

“abnormal” change, which are sites <strong>of</strong> particular<br />

leaks.<br />

This technology makes it possible to carry<br />

out temperature measurements with a precision<br />

<strong>of</strong> around 0.1 °C, which makes it possible<br />

to detect leaks <strong>of</strong> around 1 l/min/m.<br />

Developing New Projects<br />

Hydro-power development projects can be<br />

classified into three categories:<br />

– New facilities<br />

– Providing additional equipment <strong>for</strong> existing<br />

structures.<br />

This type <strong>of</strong> project makes it possible to<br />

achieve a significant increase in power<br />

(<strong>and</strong> sometimes energy) without having a<br />

major impact on the environment 1 .<br />

– Turbining <strong>of</strong> instream flows (residual<br />

water flow).<br />

<strong>VGB</strong> PowerTech 10/2006 31<br />

78