VGB POWERTECH 7 (2020) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2020). Technical Journal of the VGB PowerTech Association. Energy is us! Maintenance. Thermal waste utilisation

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 7 (2020).

Technical Journal of the VGB PowerTech Association. Energy is us!

Maintenance. Thermal waste utilisation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The Bi<strong>of</strong>ficiency Project | Part 1 <strong>VGB</strong> PowerTech 7 l <strong>2020</strong><br />

was designed from the ground up, using<br />

the results <strong>of</strong> the project. The results <strong>of</strong> this<br />

will be summarised in Part 2 <strong>of</strong> this series<br />

<strong>of</strong> technical papers.<br />

2.3.2 Pulverised fuel combustion<br />

The pulverised fuel combustion technology<br />

<strong>of</strong>fers the advantage <strong>of</strong> relatively high load<br />

flexibility combined with the highest available<br />

electrical efficiencies [9]. There<strong>for</strong>e,<br />

most big industrial boilers are pulverised<br />

fuel boilers. During the Bi<strong>of</strong>ficiency project<br />

combustion properties <strong>of</strong> pulverised biomass<br />

material, the influence <strong>of</strong> pre-treatment<br />

technologies <strong>and</strong> the use <strong>of</strong> additives<br />

were investigated in in lab-, pilot- <strong>and</strong> fullscale<br />

measurements.<br />

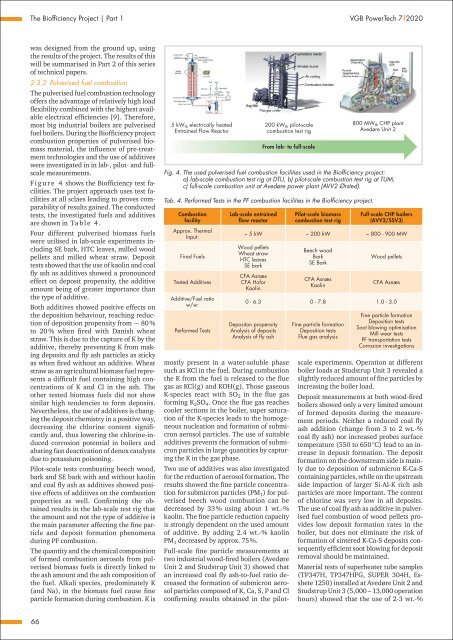

F i g u r e 4 shows the Bi<strong>of</strong>ficiency test facilities.<br />

The project approach uses test facilities<br />

at all sclaes leading to proves comparability<br />

<strong>of</strong> results gained. The conducted<br />

tests, the investigated fuels <strong>and</strong> additives<br />

are shown in Ta b l e 4 .<br />

Four different pulverised biomass fuels<br />

were utilised in lab-scale experiments including<br />

SE bark, HTC leaves, milled wood<br />

pellets <strong>and</strong> milled wheat straw. Deposit<br />

tests showed that the use <strong>of</strong> kaolin <strong>and</strong> coal<br />

fly ash as additives showed a pronounced<br />

effect on deposit propensity, the additive<br />

amount being <strong>of</strong> greater importance than<br />

the type <strong>of</strong> additive.<br />

Both additives showed positive effects on<br />

the deposition behaviour, reaching reduction<br />

<strong>of</strong> deposition propensity from ~ 80 %<br />

to 20 % when fired with Danish wheat<br />

straw. This is due to the capture <strong>of</strong> K by the<br />

additive, thereby preventing K from making<br />

deposits <strong>and</strong> fly ash particles as sticky<br />

as when fired without an additive. Wheat<br />

straw as an agricultural biomass fuel represents<br />

a difficult fuel containing high concentrations<br />

<strong>of</strong> K <strong>and</strong> Cl in the ash. The<br />

other tested biomass fuels did not show<br />

sinilar high tendencies to <strong>for</strong>m deposits.<br />

Nevertheless, the use <strong>of</strong> additives is changing<br />

the deposit chemistry in a positive way,<br />

decreasing the chlorine content significantly<br />

<strong>and</strong>, thus lowering the chlorine-induced<br />

corrosion potential in boilers <strong>and</strong><br />

abating fast deactivation <strong>of</strong> denox catalysts<br />

due to potassium poisoning.<br />

Pilot-scale tests combusting beech wood,<br />

bark <strong>and</strong> SE bark with <strong>and</strong> without kaolin<br />

<strong>and</strong> coal fly ash as additives showed positive<br />

effects <strong>of</strong> additives on the combustion<br />

properties as well. Confirming the obtained<br />

results in the lab-scale test rig that<br />

the amount <strong>and</strong> not the type <strong>of</strong> additive is<br />

the main parameter affecting the fine particle<br />

<strong>and</strong> deposit <strong>for</strong>mation phenomena<br />

during PF combustion.<br />

The quantity <strong>and</strong> the chemical composition<br />

<strong>of</strong> <strong>for</strong>med combustion aerosols from pulverised<br />

biomass fuels is directly linked to<br />

the ash amount <strong>and</strong> the ash composition <strong>of</strong><br />

the fuel. Alkali species, predominately K<br />

(<strong>and</strong> Na), in the biomass fuel cause fine<br />

particle <strong>for</strong>mation during combustion. K is<br />

5 kW th electrically heated<br />

Entrained Flow Reactor<br />

200 kW th pilot-scale<br />

combustion test rig<br />

From lab- to full-scale<br />

800 MW th CHP plant<br />

Avedøre Unit 2<br />

Fig. 4. The used pulverised fuel combustion facilities used in the Bi<strong>of</strong>ficiency project:<br />

a) lab-scale combustion test rig at DTU, b) pilot-scale combustion test rig at TUM,<br />

c) full-scale combustion unit at Avedøre power plant (AVV2 Ørsted).<br />

Tab. 4. Per<strong>for</strong>med Tests in the PF combustion facilities in the Bi<strong>of</strong>ficiency project.<br />

Combustion<br />

facility<br />

Approx. Thermal<br />

Input:<br />

Fired Fuels<br />

Tested Additives<br />

Additive/Fuel ratio<br />

w/w:<br />

Per<strong>for</strong>med Tests<br />

Lab-scale entrained<br />

flow reactor<br />

Pilot-scale biomass<br />

combustion test rig<br />

Full-scale CHP boilers<br />

(AVV2/SSV3)<br />

~ 5 kW ~ 200 kW ~ 800 - 900 MW<br />

Wood pellets<br />

Wheat straw<br />

HTC leaves<br />

SE bark<br />

CFA Asnæs<br />

CFA Ho<strong>for</strong><br />

Kaolin<br />

Beech wood<br />

Bark<br />

SE Bark<br />

CFA Asnæs<br />

Kaolin<br />

Wood pellets<br />

CFA Asnæs<br />

0 - 6.3 0 - 7.8 1.0 - 3.0<br />

Depositon propensity<br />

Analysis <strong>of</strong> deposits<br />

Analysis <strong>of</strong> fly ash<br />

Fine particle <strong>for</strong>mation<br />

Deposition tests<br />

Flue gas analysis<br />

Fine particle <strong>for</strong>mation<br />

Deposition tests<br />

Soot blowing optimisation<br />

Mill wear tests<br />

PF transportation tests<br />

Corrosion investigations<br />

mostly present in a water-soluble phase<br />

such as KCl in the fuel. During combustion<br />

the K from the fuel is released to the flue<br />

gas as KCl(g) <strong>and</strong> KOH(g). Those gaseous<br />

K-species react with SO 2 in the flue gas<br />

<strong>for</strong>ming K 2 SO 4 . Once the flue gas reaches<br />

cooler sections in the boiler, super saturation<br />

<strong>of</strong> the K-species leads to the homogeneous<br />

nucleation <strong>and</strong> <strong>for</strong>mation <strong>of</strong> submicron<br />

aerosol particles. The use <strong>of</strong> suitable<br />

additives prevents the <strong>for</strong>mation <strong>of</strong> submicron<br />

particles in large quantities by capturing<br />

the K in the gas phase.<br />

Two use <strong>of</strong> additives was also investigated<br />

<strong>for</strong> the reduction <strong>of</strong> aerosol <strong>for</strong>mation. The<br />

results showed the fine particle concentration<br />

<strong>for</strong> submicron particles (PM 1 ) <strong>for</strong> pulverised<br />

beech wood combustion can be<br />

decreased by 33 % using about 1 wt.-%<br />

kaolin. The fine particle reduction capacity<br />

is strongly dependent on the used amount<br />

<strong>of</strong> additive. By adding 2.4 wt.-% kaolin<br />

PM 1 decreased by approx. 75 %.<br />

Full-scale fine particle measurements at<br />

two industrial wood-fired boilers (Avedøre<br />

Unit 2 <strong>and</strong> Studstrup Unit 3) showed that<br />

an increased coal fly ash-to-fuel ratio decreased<br />

the <strong>for</strong>mation <strong>of</strong> submicron aerosol<br />

particles composed <strong>of</strong> K, Ca, S, P <strong>and</strong> Cl<br />

confirming results obtained in the pilotscale<br />

experiments. Operation at different<br />

boiler loads at Studstrup Unit 3 revealed a<br />

slightly reduced amount <strong>of</strong> fine particles by<br />

increasing the boiler load.<br />

Deposit measurements at both wood-fired<br />

boilers showed only a very limited amount<br />

<strong>of</strong> <strong>for</strong>med deposits during the measurement<br />

periods. Neither a reduced coal fly<br />

ash addition (change from 3 to 2 wt.-%<br />

coal fly ash) nor increased probes surface<br />

temperature (550 to 650 °C) lead to an increase<br />

in deposit <strong>for</strong>mation. The deposit<br />

<strong>for</strong>mation on the downstream side is mainly<br />

due to deposition <strong>of</strong> submicron K-Ca-S<br />

containing particles, while on the upstream<br />

side impaction <strong>of</strong> larger Si-Al-K rich ash<br />

particles are more important. The content<br />

<strong>of</strong> chlorine was very low in all deposits.<br />

The use <strong>of</strong> coal fly ash as additive in pulverised<br />

fuel combustion <strong>of</strong> wood pellets provides<br />

low deposit <strong>for</strong>mation rates in the<br />

boiler, but does not eliminate the risk <strong>of</strong><br />

<strong>for</strong>mation <strong>of</strong> sintered K-Ca-S deposits consequently<br />

efficient soot blowing <strong>for</strong> deposit<br />

removal should be maintained.<br />

Material tests <strong>of</strong> superheater tube samples<br />

(TP347H, TP347HFG, SUPER 304H, Esshete<br />

1250) installed at Avedøre Unit 2 <strong>and</strong><br />

Studstrup Unit 3 (5,000 – 13,000 operation<br />

hours) showed that the use <strong>of</strong> 2-3 wt.-%<br />

66