SUbstance flow analysis of the recycling of small waste electrical ...

SUbstance flow analysis of the recycling of small waste electrical ...

SUbstance flow analysis of the recycling of small waste electrical ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

114 Substance <strong>flow</strong> <strong>analysis</strong> <strong>of</strong> <strong>the</strong> <strong>recycling</strong> <strong>of</strong> <strong>small</strong> WEEE<br />

technological innovations enable <strong>the</strong> achievement <strong>of</strong> higher recovery rates for precious<br />

metals, obviously <strong>the</strong>y should be used.<br />

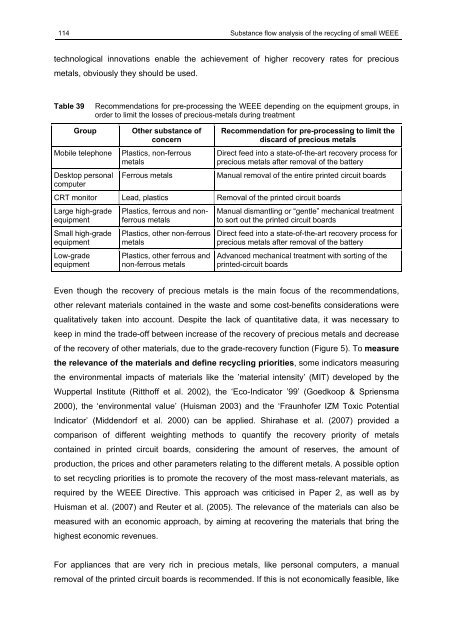

Table 39<br />

Recommendations for pre-processing <strong>the</strong> WEEE depending on <strong>the</strong> equipment groups, in<br />

order to limit <strong>the</strong> losses <strong>of</strong> precious-metals during treatment<br />

Group<br />

Mobile telephone<br />

Desktop personal<br />

computer<br />

O<strong>the</strong>r substance <strong>of</strong><br />

concern<br />

Plastics, non-ferrous<br />

metals<br />

Ferrous metals<br />

Recommendation for pre-processing to limit <strong>the</strong><br />

discard <strong>of</strong> precious metals<br />

Direct feed into a state-<strong>of</strong>-<strong>the</strong>-art recovery process for<br />

precious metals after removal <strong>of</strong> <strong>the</strong> battery<br />

Manual removal <strong>of</strong> <strong>the</strong> entire printed circuit boards<br />

CRT monitor Lead, plastics Removal <strong>of</strong> <strong>the</strong> printed circuit boards<br />

Large high-grade<br />

equipment<br />

Small high-grade<br />

equipment<br />

Low-grade<br />

equipment<br />

Plastics, ferrous and nonferrous<br />

metals<br />

Plastics, o<strong>the</strong>r non-ferrous<br />

metals<br />

Plastics, o<strong>the</strong>r ferrous and<br />

non-ferrous metals<br />

Manual dismantling or “gentle” mechanical treatment<br />

to sort out <strong>the</strong> printed circuit boards<br />

Direct feed into a state-<strong>of</strong>-<strong>the</strong>-art recovery process for<br />

precious metals after removal <strong>of</strong> <strong>the</strong> battery<br />

Advanced mechanical treatment with sorting <strong>of</strong> <strong>the</strong><br />

printed-circuit boards<br />

Even though <strong>the</strong> recovery <strong>of</strong> precious metals is <strong>the</strong> main focus <strong>of</strong> <strong>the</strong> recommendations,<br />

o<strong>the</strong>r relevant materials contained in <strong>the</strong> <strong>waste</strong> and some cost-benefits considerations were<br />

qualitatively taken into account. Despite <strong>the</strong> lack <strong>of</strong> quantitative data, it was necessary to<br />

keep in mind <strong>the</strong> trade-<strong>of</strong>f between increase <strong>of</strong> <strong>the</strong> recovery <strong>of</strong> precious metals and decrease<br />

<strong>of</strong> <strong>the</strong> recovery <strong>of</strong> o<strong>the</strong>r materials, due to <strong>the</strong> grade-recovery function (Figure 5). To measure<br />

<strong>the</strong> relevance <strong>of</strong> <strong>the</strong> materials and define <strong>recycling</strong> priorities, some indicators measuring<br />

<strong>the</strong> environmental impacts <strong>of</strong> materials like <strong>the</strong> ’material intensity’ (MIT) developed by <strong>the</strong><br />

Wuppertal Institute (Ritth<strong>of</strong>f et al. 2002), <strong>the</strong> ‘Eco-Indicator ’99’ (Goedkoop & Spriensma<br />

2000), <strong>the</strong> ‘environmental value’ (Huisman 2003) and <strong>the</strong> ‘Fraunh<strong>of</strong>er IZM Toxic Potential<br />

Indicator’ (Middendorf et al. 2000) can be applied. Shirahase et al. (2007) provided a<br />

comparison <strong>of</strong> different weighting methods to quantify <strong>the</strong> recovery priority <strong>of</strong> metals<br />

contained in printed circuit boards, considering <strong>the</strong> amount <strong>of</strong> reserves, <strong>the</strong> amount <strong>of</strong><br />

production, <strong>the</strong> prices and o<strong>the</strong>r parameters relating to <strong>the</strong> different metals. A possible option<br />

to set <strong>recycling</strong> priorities is to promote <strong>the</strong> recovery <strong>of</strong> <strong>the</strong> most mass-relevant materials, as<br />

required by <strong>the</strong> WEEE Directive. This approach was criticised in Paper 2, as well as by<br />

Huisman et al. (2007) and Reuter et al. (2005). The relevance <strong>of</strong> <strong>the</strong> materials can also be<br />

measured with an economic approach, by aiming at recovering <strong>the</strong> materials that bring <strong>the</strong><br />

highest economic revenues.<br />

For appliances that are very rich in precious metals, like personal computers, a manual<br />

removal <strong>of</strong> <strong>the</strong> printed circuit boards is recommended. If this is not economically feasible, like