- Page 1 and 2: AS-3640 ADRESS PRINTER User Manual

- Page 3 and 4: Pos: 3 /[Allgemeines]/0.0a_Note_Tra

- Page 5 and 6: 4.5.5 How to activate the emergency

- Page 7 and 8: Pos: 6 /[Allgemeines]/0.3_Abbildung

- Page 9 and 10: Figure 36: Encoder Pattern ........

- Page 11 and 12: Pos: 8 /Bedienungsanleitungen/Gerä

- Page 13 and 14: Pos: 13 /Bedienungsanleitungen/Ger

- Page 15 and 16: Pos: 20 /Bedienungsanleitungen/Ger

- Page 17 and 18: Pos: 26 /Bedienungsanleitungen/Ger

- Page 19 and 20: Pos: 30 /Bedienungsanleitungen/Ger

- Page 21 and 22: Pos: 33 /Bedienungsanleitungen/Ger

- Page 23 and 24: Pos: 35 /Bedienungsanleitungen/Ger

- Page 25 and 26: Pos: 44 /Bedienungsanleitungen/Ger

- Page 27 and 28: Pos: 46 /Bedienungsanleitungen/Ger

- Page 29 and 30: 2: Ink costs and ink range This lin

- Page 31 and 32: Pos: 48 /Bedienungsanleitungen/Ger

- Page 33 and 34: Pos: 51 /Bedienungsanleitungen/Ger

- Page 35 and 36: Pos: 54 /Bedienungsanleitungen/Ger

- Page 37: Pos: 61 /Bedienungsanleitungen/Ger

- Page 41 and 42: Pos: 65 /Bedienungsanleitungen/Ger

- Page 43 and 44: Pos: 69 /Bedienungsanleitungen/Ger

- Page 45 and 46: Pos: 72 /Bedienungsanleitungen/Ger

- Page 47 and 48: CENTAUR SEARCH ....................

- Page 49 and 50: Pos: 75.3 /Bedienungsanleitungen/Ge

- Page 51 and 52: Pos: 75.7 /Bedienungsanleitungen/Ge

- Page 53 and 54: Pos: 75.15 /Bedienungsanleitungen/G

- Page 55 and 56: Pos: 75.18 /Bedienungsanleitungen/G

- Page 57 and 58: Pos: 75.24 /Bedienungsanleitungen/G

- Page 59 and 60: Pos: 75.26 /Bedienungsanleitungen/G

- Page 61 and 62: Figure 24: Adjustment of encoder ne

- Page 63 and 64: Pos: 75.31 /Bedienungsanleitungen/G

- Page 65 and 66: Pos: 75.36 /Bedienungsanleitungen/G

- Page 67 and 68: PRINT MIRRORED When set to on, all

- Page 69 and 70: Pos: 75.47 /Bedienungsanleitungen/G

- Page 71 and 72: Pos: 75.52 /Bedienungsanleitungen/G

- Page 73 and 74: Pos: 75.57 /Bedienungsanleitungen/G

- Page 75 and 76: Pos: 75.64 /Bedienungsanleitungen/G

- Page 77 and 78: Pos: 75.72 /Bedienungsanleitungen/G

- Page 79 and 80: Relay 1 OUTPUT This feature is used

- Page 81 and 82: Pos: 75.78 /Bedienungsanleitungen/G

- Page 83 and 84: Pos: 75.81 /Bedienungsanleitungen/G

- Page 85 and 86: Pos: 75.87 /Bedienungsanleitungen/G

- Page 87 and 88: Pos: 75.95 /Bedienungsanleitungen/G

- Page 89 and 90:

Pos: 75.103 /Bedienungsanleitungen/

- Page 91 and 92:

Pos: 75.108 /Bedienungsanleitungen/

- Page 93 and 94:

Pos: 75.120 /Bedienungsanleitungen/

- Page 95 and 96:

Pos: 75.130 /Bedienungsanleitungen/

- Page 97 and 98:

Pos: 75.141 /Bedienungsanleitungen/

- Page 99 and 100:

Pos: 75.152 /Bedienungsanleitungen/

- Page 101 and 102:

Pos: 75.162 /Bedienungsanleitungen/

- Page 103 and 104:

n n c1 c2 Figure 40: Pattern A with

- Page 105 and 106:

Pos: 75.167 /Bedienungsanleitungen/

- Page 107 and 108:

Pos: 75.173 /Bedienungsanleitungen/

- Page 109 and 110:

Pos: 76.2 /Bedienungsanleitungen/Ge

- Page 111 and 112:

2. Connect the PC to the printer

- Page 113 and 114:

Pos: 76.4 /Bedienungsanleitungen/Ge

- Page 115 and 116:

Correct IP address syntax Don’t e

- Page 117 and 118:

7.3.2.1 Using a fixed IP address 1.

- Page 119 and 120:

Pos: 76.7 /Bedienungsanleitungen/Ge

- Page 121 and 122:

Pos: 77 /Bedienungsanleitungen/Ger

- Page 123 and 124:

8.1.2 How to clean an ink cartridge

- Page 125 and 126:

Pos: 84 /Bedienungsanleitungen/Ger

- Page 127 and 128:

Pos: 86 /Bedienungsanleitungen/Ger

- Page 129 and 130:

Pos: 93 /Bedienungsanleitungen/Ger

- Page 131 and 132:

Pos: 97 /Bedienungsanleitungen/Ger

- Page 133 and 134:

Pos: 99 /Bedienungsanleitungen/Ger

- Page 135 and 136:

Pos: 101.3 /Bedienungsanleitungen/G

- Page 137 and 138:

Pos: 101.6 /Bedienungsanleitungen/G

- Page 139 and 140:

Pos: 101.14 /Bedienungsanleitungen/

- Page 141 and 142:

Pos: 101.22 /Bedienungsanleitungen/

- Page 143 and 144:

Pos: 101.29 /Bedienungsanleitungen/

- Page 145 and 146:

Pos: 101.37 /Bedienungsanleitungen/

- Page 147 and 148:

Pos: 101.45 /Bedienungsanleitungen/

- Page 149 and 150:

Pos: 101.52 /Bedienungsanleitungen/

- Page 151 and 152:

Pos: 101.60 /Bedienungsanleitungen/

- Page 153 and 154:

Pos: 103 /Bedienungsanleitungen/Ger

- Page 155 and 156:

Pos: 104.8 /Bedienungsanleitungen/G

- Page 157 and 158:

Pos: 104.16 /Bedienungsanleitungen/

- Page 159 and 160:

Pos: 104.25 /Bedienungsanleitungen/

- Page 161 and 162:

Pos: 106.6 /Bedienungsanleitungen/G

- Page 163 and 164:

Pos: 106.16 /Bedienungsanleitungen/

- Page 165 and 166:

Pos: 110 /Bedienungsanleitungen/Ger

- Page 167 and 168:

Pos: 115 /Zubehör/AS-OrbitBase/R20

- Page 169 and 170:

Pos: 120 /Bedienungsanleitungen/Ger

- Page 171 and 172:

Pos: 122.1 /Bedienungsanleitungen/G

- Page 173 and 174:

Pos: 122.3 /Bedienungsanleitungen/G

- Page 175 and 176:

Pos: 122.4 /Bedienungsanleitungen/G

- Page 177 and 178:

Pos: 122.6 /Bedienungsanleitungen/G

- Page 179 and 180:

Pos: 123 /Serviceanleitungen/Gerät

- Page 181 and 182:

11.5 How to create a print file Dep

- Page 183 and 184:

Install the printer driver first Pl

- Page 185 and 186:

4 • Enable “Send to printer”

- Page 187 and 188:

11.8 How to position the paper sens

- Page 189 and 190:

The statical Teach-in mode (TM/TB)

- Page 191 and 192:

Pos: 128 /Bedienungsanleitungen/Ger

- Page 193 and 194:

Pos: 131 /Bedienungsanleitungen/Ger

- Page 195 and 196:

Narrow media and unused separation

- Page 197 and 198:

11.14 Additional display texts Unde

- Page 199 and 200:

Pos: 136 /Bedienungsanleitungen/Ger

- Page 201 and 202:

Pos: 139 /Bedienungsanleitungen/Ger

- Page 203 and 204:

Decap Time Default configuration Di

- Page 205 and 206:

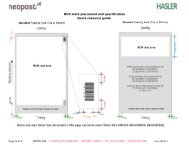

Paper recognition Paper Sensor Pape

- Page 207 and 208:

Pos: 143 /Bedienungsanleitungen/Ger

- Page 209 and 210:

=== Ende der Liste für Textmarke I