- Page 1 and 2: Ramme - Tharaniyil Second Edition A

- Page 3 and 4: This book is dedicated to all the i

- Page 5 and 6: Contents Chapter 5 Controlled Low-S

- Page 7 and 8: Contents Appendix A Product Data Sh

- Page 9 and 10: Chapter 1 Background and History o

- Page 11 and 12: The United States is the world's se

- Page 13 and 14: are currently installed on about 25

- Page 15 and 16: problems. In the late 1920’s, cin

- Page 17 and 18: Chapter 2 CCPs and Electric Power

- Page 19 and 20: for loading dry bulk semi tankers o

- Page 21 and 22: Figure 2-2: Basic Diagram of an IGC

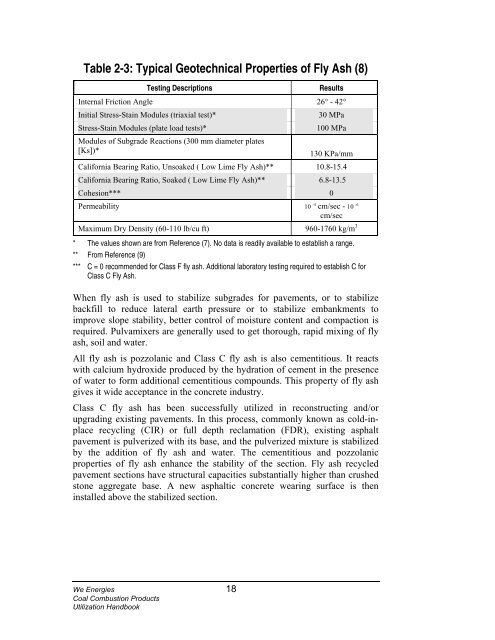

- Page 23 and 24: Properties of Fly Ash Fly ash is a

- Page 25: for air entraining admixtures, maki

- Page 29 and 30: Table 2-6: Geotechnical Properties

- Page 31 and 32: Table 2-9 shows the chemical compos

- Page 33 and 34: Table 2-12: Typical Chemical Compos

- Page 35 and 36: The following coal fired power plan

- Page 37 and 38: All bottom ash is removed as necess

- Page 39 and 40: ottom ash is removed by a hydraulic

- Page 41 and 42: Chapter 3 Properties of We Energie

- Page 43 and 44: that distribute and test fly ash to

- Page 45 and 46: Physical, Chemical and Mechanical P

- Page 47 and 48: However, some engineering propertie

- Page 49 and 50: ----------------------------U.S. ST

- Page 51 and 52: Results of Testing to AASHTO Standa

- Page 53 and 54: Table 3-8: Summary of We Energies B

- Page 55 and 56: Chapter 4 Concrete and Concrete Ma

- Page 57 and 58: alumina in the pozzolan may also re

- Page 59 and 60: Dunstan summarized his work in term

- Page 61 and 62: The level of shrinkage strains depe

- Page 63 and 64: strength tests were performed at va

- Page 65 and 66: Discussion of Test Results - 4,000

- Page 67 and 68: Other important observations from t

- Page 69 and 70: Figure 4-3: Compressive Strength vs

- Page 71 and 72: 300 290 AMOUNT OF WATER, lbs 280 27

- Page 73 and 74: Table 4-8: PPPP ASTM C618 Class C F

- Page 75 and 76: The final setting time for 5000 psi

- Page 77 and 78:

Table 4-12: Length Change* NON-AIR-

- Page 79 and 80:

Table 4-14: Freeze-Thaw Tests* (Air

- Page 81 and 82:

Abrasion resistance tests were perf

- Page 83 and 84:

Table 4-16: Compressive Strength Te

- Page 85 and 86:

4 DEPTH OF WEAR, mm @ 60 Minutes 3.

- Page 87 and 88:

Table 4-19: Mixture Proportions Usi

- Page 89 and 90:

12000 COMPRESSIVE STRENGTH, PSI 100

- Page 91 and 92:

Table 4-21: Air Permeability Test R

- Page 93 and 94:

Table 4-22: Water Permeability Test

- Page 95 and 96:

Table 4-23: Chloride Permeability T

- Page 97 and 98:

Tax Incremental Financing (TIF) was

- Page 99 and 100:

Figure 4-20 : Maple Avenue roadway

- Page 101 and 102:

Figure 4-22: Finishing touch to We

- Page 103 and 104:

Table 4-26: Concrete Mixture and Si

- Page 105 and 106:

6. The high-volume Class C fly ash

- Page 107 and 108:

Table 4-31: Average Tensile Strengt

- Page 109 and 110:

Table 4-35: Changes in Ultrasonic P

- Page 111 and 112:

Table 4-38: Results of De-Icing Sal

- Page 113 and 114:

Table 4-40: Abrasion Resistance of

- Page 115 and 116:

Summary Based on the data recorded

- Page 117 and 118:

3.00 M 101.5 MM WRAPPED UNDERDRAIN

- Page 119 and 120:

mixture and concrete mixture. Also,

- Page 121 and 122:

Testing Program The testing program

- Page 123 and 124:

Test Results Table 4-46 shows the c

- Page 125 and 126:

Fly Ash Concrete for Precast/Prestr

- Page 127 and 128:

Table 4-49: Concrete Mixture Propor

- Page 129 and 130:

Figure 4-27: Electrical Resistance

- Page 131 and 132:

Table 4-51: Electrical Properties o

- Page 133 and 134:

fly ash by weight of total cementit

- Page 135 and 136:

Table 4-53: Compressive Strength of

- Page 137 and 138:

Chapter 5 Controlled Low-Strength

- Page 139 and 140:

Table 5-1: Mixture Proportions and

- Page 141 and 142:

1800 COMPRESSIVE STRENGTH, psi 1600

- Page 143 and 144:

Table 5-3: Chemical and Fineness Te

- Page 145 and 146:

1800 COMPRESSIVE STRENGTH, psi 1600

- Page 147 and 148:

and corresponding compressive stren

- Page 149 and 150:

conductivity tests were conducted u

- Page 151 and 152:

It can be concluded from this resea

- Page 153 and 154:

Table 5-13: Compressive Strength of

- Page 155 and 156:

(4) Compatible with copper, aluminu

- Page 157 and 158:

Mechanical Properties The compressi

- Page 159 and 160:

Figure 5-10: Electrical permeabilit

- Page 161 and 162:

Pilot Projects Using We Energies CL

- Page 163 and 164:

WisDOT Low Permeability CLSM with W

- Page 165 and 166:

material for foundations, changing

- Page 167 and 168:

Chapter 6 Commercial Applications

- Page 169 and 170:

The report also evaluated frost sus

- Page 171 and 172:

Field Study Following the initial s

- Page 173 and 174:

Figure 6-3: Bottom ash base course

- Page 175 and 176:

Table 6-2: Permeability and Drainag

- Page 177 and 178:

Bottom Ash as an Aggregate in Aspha

- Page 179 and 180:

Table 6-4: Total Elemental Analysis

- Page 181 and 182:

We Energies Bottom Ash as a Soil In

- Page 183 and 184:

The coal combustion materials landf

- Page 185 and 186:

The only other compounds detected t

- Page 187 and 188:

affect combustion. The resulting fl

- Page 189 and 190:

Table 6-7: Dry-Cast Concrete Block

- Page 191 and 192:

Table 6-10 Compressive Strength of

- Page 193 and 194:

Chapter 7 Fly Ash Stabilized Cold

- Page 195 and 196:

Using the back-calculated SN values

- Page 197 and 198:

Falling Weight Deflectometer tests

- Page 199 and 200:

unconfined compressive strength of

- Page 201 and 202:

Chapter 8 Fly Ash Metal Matrix Com

- Page 203 and 204:

The green density of the aluminum f

- Page 205 and 206:

Table 8-1: Alloy Samples Tested in

- Page 207 and 208:

Cenospheres Cenospheres are hollow,

- Page 209 and 210:

Chapter 9 Environmental Considerat

- Page 211 and 212:

judgment is required for new applic

- Page 213 and 214:

Table 9-2: NR 538 Fly Ash Analysis

- Page 215 and 216:

Table 9-3: NR 538 Fly Ash Analysis

- Page 217 and 218:

Table 9-4: NR 538 Bottom Ash Analys

- Page 219 and 220:

Table 9-5: NR 538 Bottom Ash Analys

- Page 221 and 222:

Table 9-7: ASTM D3987 Extraction An

- Page 223 and 224:

Table 9-8: Typical Heavy Metals Fou

- Page 225 and 226:

The voluntary C 2 P 2 Challenge Pro

- Page 227 and 228:

General Usage - NR 538 Applicabilit

- Page 229 and 230:

* Use Property Owner Notification -

- Page 231 and 232:

Mercury Removal-Ash Beneficiation (

- Page 233 and 234:

the air slide inlet was set at 538

- Page 235 and 236:

equired removal temperatures of 813

- Page 237 and 238:

Chapter 10 Minergy LWA - Structura

- Page 239 and 240:

Chapter 11 Sample Specifications

- Page 241 and 242:

Part 2 - Products 2.01 Concrete Mat

- Page 243 and 244:

3.02 Embedded Items A. All sleeves,

- Page 245 and 246:

C. Provide adequate number of units

- Page 247 and 248:

B. Reinforce or replace deficient w

- Page 249 and 250:

show the strength of masonry strong

- Page 251 and 252:

3.02 Bottom Ash Placing and Compact

- Page 253 and 254:

3. The CLSM shall meet the followin

- Page 255 and 256:

3.02 CLSM Depositing A. CLSM shall

- Page 257 and 258:

11.5 Sample Specification for We En

- Page 259 and 260:

D. Basis of Payment This item, meas

- Page 261 and 262:

If the reprocessed asphaltic base-f

- Page 263 and 264:

Chapter 12 References 1. American

- Page 265 and 266:

33. University of Wisconsin-Milwauk

- Page 267 and 268:

69. Naik, T.R., Kraus, R.N., and Si

- Page 269 and 270:

Appendix A Product Data Sheets Min

- Page 271 and 272:

Personal Protective Equipment Speci

- Page 273 and 274:

FirstAid Eyes Inhalation Ingestion

- Page 275 and 276:

Appendix B Radioactivity in Coal a

- Page 277 and 278:

annual number of curies of each of

- Page 279 and 280:

is divided among cosmic (30 mrem),

- Page 281 and 282:

constructed with fly ash building m

- Page 283 and 284:

Appendix C Field Guide for Recycli

- Page 285 and 286:

‣ Blend the fly ash and prepared

- Page 287 and 288:

Index AASHTO See American Associati

- Page 289 and 290:

Index Backfill material, 6, 43, 138

- Page 291 and 292:

Index Disposal costs, 5 See also La

- Page 293 and 294:

Index Pavement, 26, 109, 187; botto

- Page 295 and 296:

Index Size, boiler slag, 22; bottom

- Page 297:

About the Authors Bruce W. Ramme B