ComputerAided_Design_Engineering_amp_Manufactur.pdf

ComputerAided_Design_Engineering_amp_Manufactur.pdf

ComputerAided_Design_Engineering_amp_Manufactur.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A ik<br />

� ‘U’ and is in a cycle that has a place with more than one input transition. We now apply the<br />

tool to the synthesis of an automated manufacturing system (Figure 8.11).<br />

Description of a <strong>Manufactur</strong>ing System<br />

This automated manufacturing system consists of the following major components (Table 8.3): two<br />

entries, two exits, five machines, two robots, two automatic guided vehicles (AGV), and related conveyors.<br />

It can produce two types of products. An unlimited source of raw materials is assumed. Once machines,<br />

robots, or AGVs start any operation, they cannot be interrupted until the work is complete. We now<br />

build up a well-behaved PN model.<br />

Modeling and Synthesis Process<br />

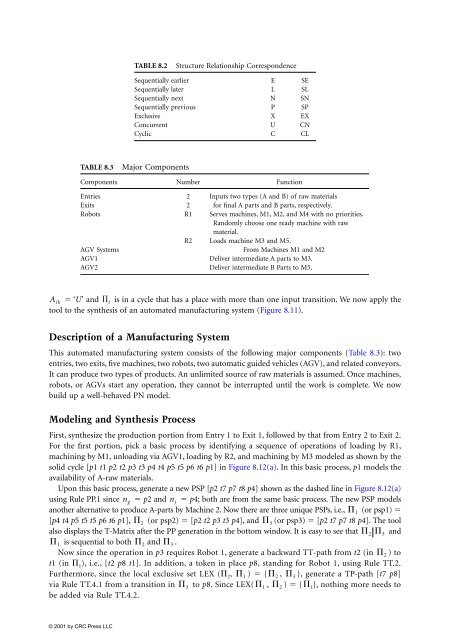

TABLE 8.2 Structure Relationship Correspondence<br />

Sequentially earlier E SE<br />

Sequentially later L SL<br />

Sequentially next N SN<br />

Sequentially previous P SP<br />

Exclusive X EX<br />

Concurrent U CN<br />

Cyclic C CL<br />

TABLE 8.3 Major Components<br />

Components Number Function<br />

Entries 2 Inputs two types (A and B) of raw materials<br />

Exits 2 for final A parts and B parts, respectively.<br />

Robots R1 Serves machines, M1, M2, and M4 with no priorities.<br />

Randomly choose one ready machine with raw<br />

material.<br />

R2 Loads machine M3 and M5.<br />

AGV Systems From Machines M1 and M2<br />

AGV1 Deliver intermediate A parts to M3.<br />

AGV2 Deliver intermediate B Parts to M5.<br />

� i<br />

First, synthesize the production portion from Entry 1 to Exit 1, followed by that from Entry 2 to Exit 2.<br />

For the first portion, pick a basic process by identifying a sequence of operations of loading by R1,<br />

machining by M1, unloading via AGV1, loading by R2, and machining by M3 modeled as shown by the<br />

solid cycle [p1 t1 p2 t2 p3 t3 p4 t4 p5 t5 p6 t6 p1] in Figure 8.12(a). In this basic process, p1 models the<br />

availability of A-raw materials.<br />

Upon this basic process, generate a new PSP [p2 t7 p7 t8 p4] shown as the dashed line in Figure 8.12(a)<br />

using Rule PP.1 since ng � p2 and nj � p4; both are from the same basic process. The new PSP models<br />

another alternative to produce A-parts by Machine 2. Now there are three unique PSPs, i.e., �1 (or psp1) �<br />

[p4 t4 p5 t5 t5 p6 t6 p1], �2 (or psp2) � [p2 t2 p3 t3 p4], and �3 (or psp3) � [p2 t7 p7 t8 p4]. The tool<br />

also displays the T-Matrix after the PP generation in the bottom window. It is easy to see that �2 �3 and<br />

�1 is sequential to both �2 and �3 .<br />

Now since the operation in p3 requires Robot 1, generate a backward TT-path from t2 (in �2 ) to<br />

t1 (in �1), i.e., [t2 p8 t1]. In addition, a token in place p8, standing for Robot 1, using Rule TT.2.<br />

Furthermore, since the local exclusive set LEX (�2, �1 ) � { �2 , �3 }, generate a TP-path [t7 p8]<br />

via Rule TT.4.1 from a transition in �3 to p8. Since LEX( �1 , �2 ) � { �1}, nothing more needs to<br />

be added via Rule TT.4.2.