- Page 1 and 2: COMPUTER-AIDED DESIGN, ENGINEERING,

- Page 3 and 4: Library of Congress Cataloging-in-P

- Page 5 and 6: Editor Cornelius T. Leondes, B.S.,

- Page 7 and 8: Chapter 1 Chapter 2 Chapter 3 Chapt

- Page 9 and 10: the implementation of the IPD syste

- Page 11 and 12: In our IPD system implementations,

- Page 13 and 14: 2. Specification of analysis-specif

- Page 15 and 16: FIGURE 1.2 base or the design insta

- Page 17 and 18: FIGURE 1.4 System architecture of t

- Page 19 and 20: of a beam is considered for FEA. Th

- Page 21 and 22: FIGURE 1.7 through the control expe

- Page 23 and 24: 2. machining facility (e.g., gang m

- Page 25 and 26: from the FBDS. The user also specif

- Page 27 and 28: Depending on the type of feature to

- Page 29 and 30: TABLE 1.6 Tolerance synthesis is de

- Page 31 and 32: FIGURE 1.12 Display of the NC tool

- Page 33 and 34: component geometric entities and va

- Page 35 and 36: FIGURE 1.14 The system architecture

- Page 37 and 38: TABLE 1.10 User Input for the Toler

- Page 39 and 40: TABLE 1.11 Tolerance Specifications

- Page 41 and 42: 7. Z. Young and I. R. Groose. A rul

- Page 43 and 44: FIGURE 2.1 Tool paths generated for

- Page 45 and 46: FIGURE 2.2 sented by instances of f

- Page 47: TABLE 2.1 A CAD-Generated Hole Conf

- Page 51 and 52: FIGURE 2.8 fixture for the machinin

- Page 53 and 54: FIGURE 2.10 or best-fit, or the cur

- Page 55 and 56: FIGURE 2.11 Linear approximation of

- Page 57 and 58: FIGURE 2.13 Circular approximation

- Page 59 and 60: FIGURE 2.14(b) Circular approximati

- Page 61 and 62: FIGURE 2.16 Types of biarcs. FIGURE

- Page 63 and 64: FIGURE 2.18 Approximation of scanne

- Page 65 and 66: FIGURE 2.20 A touch trigger probe c

- Page 67 and 68: TABLE 2.4 Substitute Elements in CM

- Page 69 and 70: FIGURE 2.21 CMM planning requiremen

- Page 71 and 72: Product Model Representation for Co

- Page 73 and 74: © 2001 by CRC Press LLC TABLE 2.5

- Page 75 and 76: TABLE 2.7 Partial Listing of Dimens

- Page 77 and 78: 24. Makinouchi, S., Okamoto, M., an

- Page 79 and 80: Bijan Shirinzadeh Monash University

- Page 81 and 82: FIGURE 3.1 Trends in flexible manuf

- Page 83 and 84: FIGURE 3.3 and constrain different

- Page 85 and 86: Other Fixturing Techniques There ar

- Page 87 and 88: FIGURE 3.6 contact point. The geome

- Page 89 and 90: FIGURE 3.8 The vertical support fix

- Page 91 and 92: and moments about the contact point

- Page 93 and 94: een identified, the normals are use

- Page 95 and 96: one of choosing the variables: such

- Page 97 and 98: Fixture Module Location An importan

- Page 99 and 100:

FIGURE 3.15 Illustration of functio

- Page 101 and 102:

FIGURE 3.18 Minimum separation test

- Page 103 and 104:

direction) the face, respectively.

- Page 105 and 106:

FIGURE 3.21 Software structure for

- Page 107 and 108:

3.8 Conclusion A reconfigurable fix

- Page 109 and 110:

Heui Jae Pahk Seoul National Univer

- Page 111 and 112:

FIGURE 4.1(b) Conceptual framework

- Page 113 and 114:

4.3 Measurement Points Sampling and

- Page 115 and 116:

Surface S2 Measurement Path FIGURE

- Page 117 and 118:

FIGURE 4.4 Rough phase alignment ba

- Page 119 and 120:

deviation between the nominal CAD d

- Page 121 and 122:

FIGURE 4.6(a) Sum of squares distan

- Page 123 and 124:

FIGURE 4.7(c) Trailing edge. (c) th

- Page 125 and 126:

FIGURE 4.8(a) Profile tolerance of

- Page 127 and 128:

The calculated minimum form error i

- Page 129 and 130:

FIGURE 4.11(a) A typical mold havin

- Page 131 and 132:

FIGURE 4.11(d) Inspection results f

- Page 133 and 134:

FIGURE 4.12(c) Maximum deviation (p

- Page 135 and 136:

5.1 Introduction Developments in th

- Page 137 and 138:

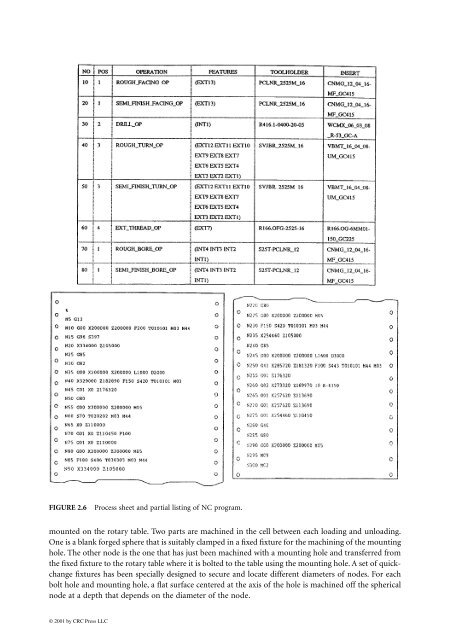

process plan for a part (Figure 5.3

- Page 139 and 140:

FIGURE 5.5 leading to the developme

- Page 141 and 142:

the previously stored process plan

- Page 143 and 144:

FIGURE 5.7 Techniques of defining a

- Page 145 and 146:

Feature Recognition and Extraction

- Page 147 and 148:

in relation to another feature (e.g

- Page 149 and 150:

FIGURE 5.9 Framework for building a

- Page 151 and 152:

FIGURE 5.10 Process plan content.

- Page 153 and 154:

FIGURE 5.12 Schematic sketch of the

- Page 155 and 156:

Several techniques of defining a fe

- Page 157 and 158:

TABLE 5.1 Data Structure for Repres

- Page 159 and 160:

FIGURE 5.16 Classification of the t

- Page 161 and 162:

system to ensure that the part bein

- Page 163 and 164:

FIGURE 5.19 Graphical model of the

- Page 165 and 166:

TABLE 5.4 Data Structure for Repres

- Page 167 and 168:

FIGURE 5.20 Mapping between machini

- Page 169 and 170:

algorithms. (Some details of the pr

- Page 171 and 172:

FIGURE 5.24 An example rotational p

- Page 173 and 174:

FIGURE 5.26 Down_face-turn-up_face

- Page 175 and 176:

FIGURE 5.27 Procedure for machine t

- Page 177 and 178:

FIGURE 5.28 Determining the number

- Page 179 and 180:

DL is needed to be set only if the

- Page 181 and 182:

FIGURE 5.31 Operation sequencing co

- Page 183 and 184:

Cutting Tool Selection Selection of

- Page 185 and 186:

1. A tool is searched for in the da

- Page 187 and 188:

FIGURE 5.32 Inputs to optimization

- Page 189 and 190:

When these values are substituted,

- Page 191 and 192:

Usually, maximum and minimum speed

- Page 193 and 194:

FIGURE 5.33 Solution methodology.

- Page 195 and 196:

TABLE 5.6 Process Plan Internal Rep

- Page 197 and 198:

In a strict theoretical perspective

- Page 199 and 200:

18. Domazet, D. S. and Lu, S. C. Y,

- Page 201 and 202:

63. Prasad, A. V. S. R. K., Rao, P.

- Page 203 and 204:

CAD systems. The sample consists of

- Page 205 and 206:

learn to master the new system. An

- Page 207 and 208:

Although researchers appear to agre

- Page 209 and 210:

Link and Zmud28 found that organic

- Page 211 and 212:

Informal Training Informal CAD trai

- Page 213 and 214:

informal training programs, felt th

- Page 215 and 216:

6. C. A. Beatty, Tall Tales and Rea

- Page 217 and 218:

A.Y.C. Nee National University of S

- Page 219 and 220:

FIGURE 7.1 Planning, design, and ma

- Page 221 and 222:

A metal stamping can have the follo

- Page 223 and 224:

FIGURE 7.3 Strips used to notch out

- Page 225 and 226:

A Skeletal Approach for the Recogni

- Page 227 and 228:

These findings can be used to devel

- Page 229 and 230:

Semi-Direct Piloting In cases where

- Page 231 and 232:

a larger value, the die operations

- Page 233 and 234:

FIGURE 7.9 Symbolic relationship be

- Page 235 and 236:

FIGURE 7.11 The shape of the envelo

- Page 237 and 238:

TABLE 7.1 Schema for the Generation

- Page 239 and 240:

strong reasons to support a move to

- Page 241 and 242:

FIGURE 7.16 3-D CAD model of a part

- Page 243 and 244:

References Cheok, B.T. et al. (1994

- Page 245 and 246:

include the once forbidden generati

- Page 247 and 248:

A temporal matrix (T-Matrix) is pro

- Page 249 and 250:

FIGURE 8.1 A basic process. (From R

- Page 251 and 252:

FIGURE 8.4(a) Generate a new IG usi

- Page 253 and 254:

Note if the pair of nodes are both

- Page 255 and 256:

TABLE 8.1 Summary of the Rules Cond

- Page 257 and 258:

The correctness of these rules is e

- Page 259 and 260:

needs to show that after each full

- Page 261 and 262:

ule is violated, a warning should b

- Page 263 and 264:

Π1 Π3 Π4 FIGURE 8.8(a) After add

- Page 265 and 266:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

- Page 267 and 268:

A ik � ‘U’ and is in a cycle

- Page 269 and 270:

FIGURE 8.12(a) Add [p2 t7 p7 t8 p4]

- Page 271 and 272:

FIGURE 8.12(c) Add a token to p8 vi

- Page 273 and 274:

FIGURE 8.12(e) Add [p8 t9 p14 t10 p

- Page 275 and 276:

FIGURE 8.13 An example of rule TT.0

- Page 277 and 278:

FIGURE 8.14 A GPN model of a machin

- Page 279 and 280:

FIGURE 8.15(b) The first exclusive

- Page 281 and 282:

FIGURE 8.15(d) The last exclusive T

- Page 283 and 284:

FIGURE 8.15(f) After entering the a

- Page 285 and 286:

FIGURE 8.15(h) Completion of Compon

- Page 287 and 288:

FIGURE 8.15(j) Two PP-generations:

- Page 289 and 290:

FIGURE 8.15(l) The last exclusive T

- Page 291 and 292:

t1 t5 p1 p5 t6 (a) t2 t3 t4 2 2 p2

- Page 293 and 294:

FIGURE 8.17 An example of partial f

- Page 295 and 296:

Theorem 10: If pi → pk in a synth

- Page 297 and 298:

Note that control transitions are o

- Page 299 and 300:

t j than the lower at , it indicate

- Page 301 and 302:

• Programming logic and VLSI arra

- Page 303 and 304:

7. Chao, D. Y. and D. T. Wang, Appl

- Page 305 and 306:

53. Villaroel, J. L., J. Martinez,

- Page 307 and 308:

q u : the numerator of the least ra

- Page 309 and 310:

geometric modeling, engineering ana

- Page 311 and 312:

In dimension driven or parametric d

- Page 313 and 314:

FIGURE 9.3 configuration of bodies

- Page 315 and 316:

FIGURE 9.6 FIGURE 9.7 Geometric Int

- Page 317 and 318:

FIGURE 9.8 Intersection of degrees

- Page 319 and 320:

will introduce a way to propagate p

- Page 321 and 322:

Completeness of Dimensions Complete

- Page 323 and 324:

FIGURE 9.12 3-D constraints. © 200

- Page 325 and 326:

The distance constraint from pt �

- Page 327 and 328:

therefore: Now merge the lists and

- Page 329 and 330:

Quantity analysis methods have the

- Page 331 and 332:

y a revolute joint. By selecting al