Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 104<br />

Pump <strong>Repair</strong><br />

Titanium Putty<br />

29/3/85<br />

Smith College Power Plant<br />

Utility Power Generation<br />

Problem:<br />

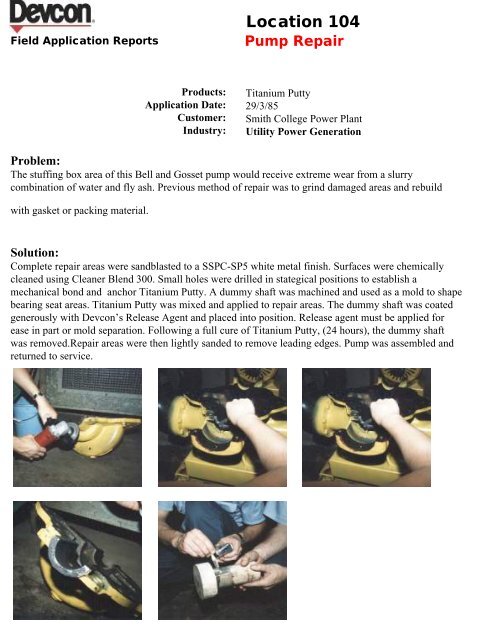

The stuffing box area of this Bell <strong>and</strong> Gosset pump would receive extreme wear from a slurry<br />

combination of water <strong>and</strong> fly ash. Previous method of repair was to grind damaged areas <strong>and</strong> rebuild<br />

with gasket or packing material.<br />

Solution:<br />

Complete repair areas were s<strong>and</strong>blasted to a SSPC-SP5 white metal finish. Surfaces were chemically<br />

cleaned using Cleaner Blend 300. Small holes were drilled in stategical positions to establish a<br />

mechanical bond <strong>and</strong> anchor Titanium Putty. A dummy shaft was machined <strong>and</strong> used as a mold to shape<br />

bearing seat areas. Titanium Putty was mixed <strong>and</strong> applied to repair areas. The dummy shaft was coated<br />

generously with <strong>Devcon</strong>’s Release Agent <strong>and</strong> placed into position. Release agent must be applied for<br />

ease in part or mold separation. Following a full cure of Titanium Putty, (24 hours), the dummy shaft<br />

was removed.<strong>Repair</strong> areas were then lightly s<strong>and</strong>ed to remove leading edges. Pump was assembled <strong>and</strong><br />

returned to service.