Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 109<br />

Bearing Race <strong>Repair</strong><br />

Plastic Steel® Liquid / Plastic Steel® Putty<br />

9/1/83<br />

Stephens Adamson Incorporated<br />

Transportation Heavy Duty<br />

Equipment Manufacturing<br />

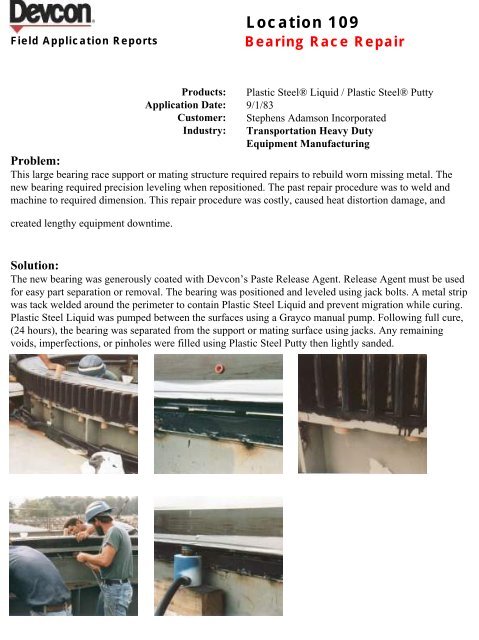

Problem:<br />

This large bearing race support or mating structure required repairs to rebuild worn missing metal. The<br />

new bearing required precision leveling when repositioned. The past repair procedure was to weld <strong>and</strong><br />

machine to required dimension. This repair procedure was costly, caused heat distortion damage, <strong>and</strong><br />

created lengthy equipment downtime.<br />

Solution:<br />

The new bearing was generously coated with <strong>Devcon</strong>’s Paste Release Agent. Release Agent must be used<br />

for easy part separation or removal. The bearing was positioned <strong>and</strong> leveled using jack bolts. A metal strip<br />

was tack welded around the perimeter to contain Plastic Steel Liquid <strong>and</strong> prevent migration while curing.<br />

Plastic Steel Liquid was pumped between the surfaces using a Grayco manual pump. Following full cure,<br />

(24 hours), the bearing was separated from the support or mating surface using jacks. Any remaining<br />

voids, imperfections, or pinholes were filled using Plastic Steel Putty then lightly s<strong>and</strong>ed.