Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 115<br />

Water Box Cover <strong>Repair</strong><br />

Ceramic <strong>Repair</strong> Putty / Brushable Ceramic<br />

6/1/90<br />

Sun Oil Company<br />

Petrochemical Gasoline Manufacturing<br />

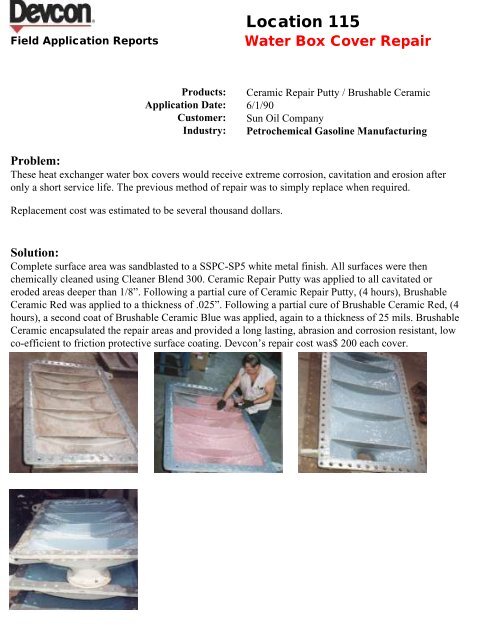

Problem:<br />

These heat exchanger water box covers would receive extreme corrosion, cavitation <strong>and</strong> erosion after<br />

only a short service life. The previous method of repair was to simply replace when required.<br />

Replacement cost was estimated to be several thous<strong>and</strong> dollars.<br />

Solution:<br />

Complete surface area was s<strong>and</strong>blasted to a SSPC-SP5 white metal finish. All surfaces were then<br />

chemically cleaned using Cleaner Blend 300. Ceramic <strong>Repair</strong> Putty was applied to all cavitated or<br />

eroded areas deeper than 1/8”. Following a partial cure of Ceramic <strong>Repair</strong> Putty, (4 hours), Brushable<br />

Ceramic Red was applied to a thickness of .025”. Following a partial cure of Brushable Ceramic Red, (4<br />

hours), a second coat of Brushable Ceramic Blue was applied, again to a thickness of 25 mils. Brushable<br />

Ceramic encapsulated the repair areas <strong>and</strong> provided a long lasting, abrasion <strong>and</strong> corrosion resistant, low<br />

co-efficient to friction protective surface coating. <strong>Devcon</strong>’s repair cost was$ 200 each cover.