Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 43<br />

Cement Agitator <strong>Repair</strong><br />

Wear Guard Fine Load<br />

9/21/92<br />

Chicago Road Service<br />

Cement Manufacturing<br />

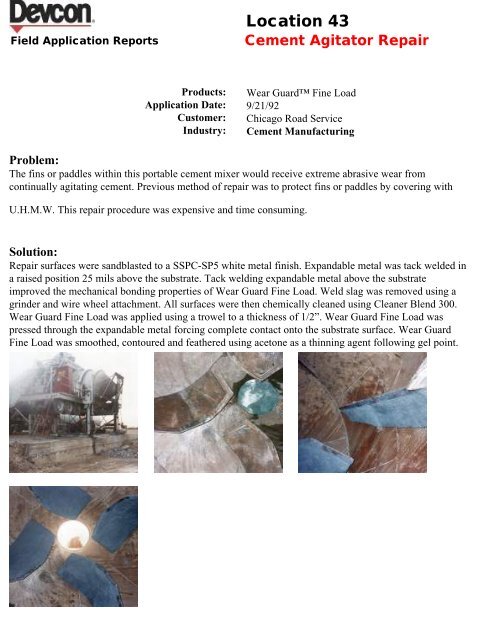

Problem:<br />

The fins or paddles within this portable cement mixer would receive extreme abrasive wear from<br />

continually agitating cement. Previous method of repair was to protect fins or paddles by covering with<br />

U.H.M.W. This repair procedure was expensive <strong>and</strong> time consuming.<br />

Solution:<br />

<strong>Repair</strong> surfaces were s<strong>and</strong>blasted to a SSPC-SP5 white metal finish. Exp<strong>and</strong>able metal was tack welded in<br />

a raised position 25 mils above the substrate. Tack welding exp<strong>and</strong>able metal above the substrate<br />

improved the mechanical bonding properties of Wear Guard Fine Load. Weld slag was removed using a<br />

grinder <strong>and</strong> wire wheel attachment. All surfaces were then chemically cleaned using Cleaner Blend 300.<br />

Wear Guard Fine Load was applied using a trowel to a thickness of 1/2”. Wear Guard Fine Load was<br />

pressed through the exp<strong>and</strong>able metal forcing complete contact onto the substrate surface. Wear Guard<br />

Fine Load was smoothed, contoured <strong>and</strong> feathered using acetone as a thinning agent following gel point.