Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 23<br />

Screw Conveyor Trough<br />

<strong>Repair</strong><br />

Ceramic <strong>Repair</strong>, Brushable Ceramic Blue/Red<br />

3/23/00<br />

West Virginia Synthetic Fuels<br />

Coal Prep<br />

Problem:<br />

Dry coal “fines “ would collect on the trough of the screw conveyer <strong>and</strong> on the screw flyghts. The<br />

constant abrasion will cause cavataion in the trough <strong>and</strong> prevent proper conveying of the coal. Thusly<br />

the trough needed to be rebuilt back to its close tolerance to the flyghts.<br />

Solution:<br />

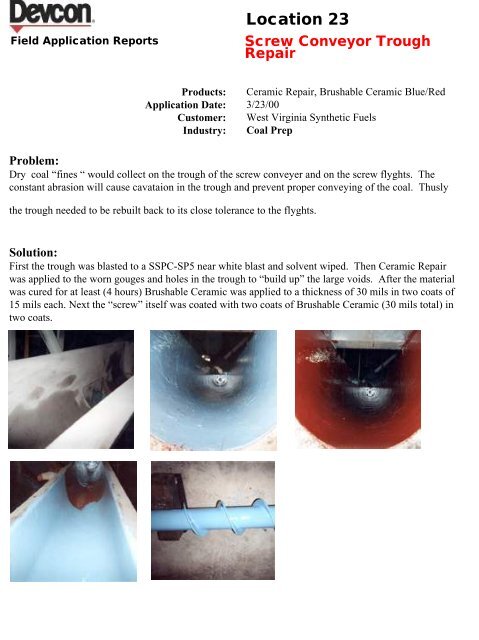

First the trough was blasted to a SSPC-SP5 near white blast <strong>and</strong> solvent wiped. Then Ceramic <strong>Repair</strong><br />

was applied to the worn gouges <strong>and</strong> holes in the trough to “build up” the large voids. After the material<br />

was cured for at least (4 hours) Brushable Ceramic was applied to a thickness of 30 mils in two coats of<br />

15 mils each. Next the “screw” itself was coated with two coats of Brushable Ceramic (30 mils total) in<br />

two coats.