Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 27<br />

Scrubber Wet/Dry<br />

Interface <strong>Repair</strong><br />

Wear Guard Fine Load / Brushable Ceramic<br />

5/30/95<br />

Utah Power [Light Hunter Plant]<br />

Utility Power Generation<br />

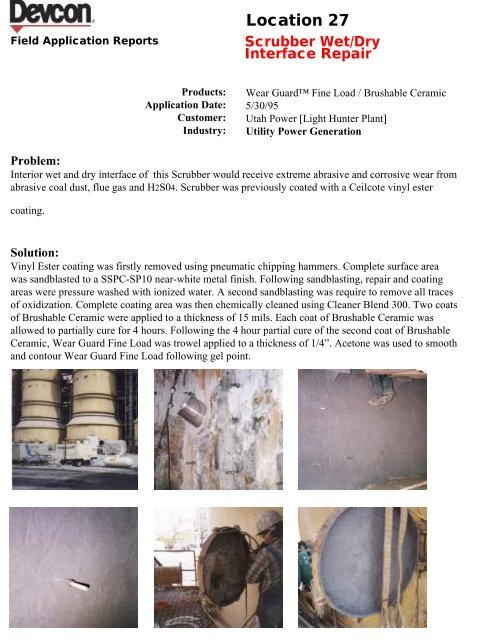

Problem:<br />

Interior wet <strong>and</strong> dry interface of this Scrubber would receive extreme abrasive <strong>and</strong> corrosive wear from<br />

abrasive coal dust, flue gas <strong>and</strong> H2S04. Scrubber was previously coated with a Ceilcote vinyl ester<br />

coating.<br />

Solution:<br />

Vinyl Ester coating was firstly removed using pneumatic chipping hammers. Complete surface area<br />

was s<strong>and</strong>blasted to a SSPC-SP10 near-white metal finish. Following s<strong>and</strong>blasting, repair <strong>and</strong> coating<br />

areas were pressure washed with ionized water. A second s<strong>and</strong>blasting was require to remove all traces<br />

of oxidization. Complete coating area was then chemically cleaned using Cleaner Blend 300. Two coats<br />

of Brushable Ceramic were applied to a thickness of 15 mils. Each coat of Brushable Ceramic was<br />

allowed to partially cure for 4 hours. Following the 4 hour partial cure of the second coat of Brushable<br />

Ceramic, Wear Guard Fine Load was trowel applied to a thickness of 1/4”. Acetone was used to smooth<br />

<strong>and</strong> contour Wear Guard Fine Load following gel point.