Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 42<br />

Coupling Bolt <strong>Repair</strong><br />

Titanium Putty<br />

1/2/92<br />

Edison Sault Electric Company<br />

Utility Power Generation<br />

Problem:<br />

These coupling bolts used to join the turbine <strong>and</strong> generator together would receive extreme abrasive<br />

wear from the secondary leather coupling. The past repair method was to remanufacture new coupling<br />

bolts when required.<br />

Solution:<br />

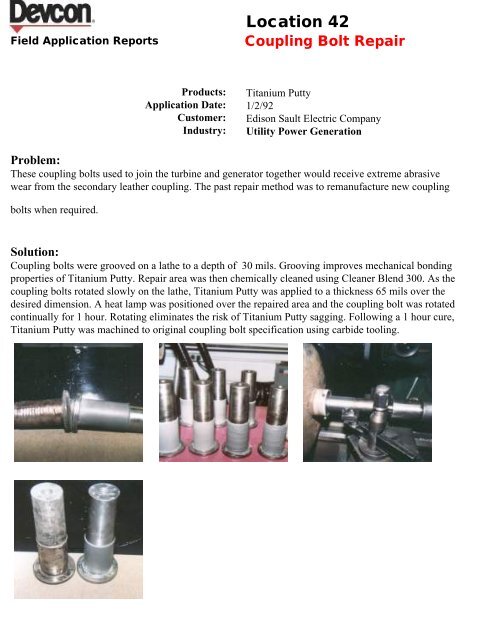

Coupling bolts were grooved on a lathe to a depth of 30 mils. Grooving improves mechanical bonding<br />

properties of Titanium Putty. <strong>Repair</strong> area was then chemically cleaned using Cleaner Blend 300. As the<br />

coupling bolts rotated slowly on the lathe, Titanium Putty was applied to a thickness 65 mils over the<br />

desired dimension. A heat lamp was positioned over the repaired area <strong>and</strong> the coupling bolt was rotated<br />

continually for 1 hour. Rotating eliminates the risk of Titanium Putty sagging. Following a 1 hour cure,<br />

Titanium Putty was machined to original coupling bolt specification using carbide tooling.