Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 139<br />

Ball Mill <strong>Repair</strong><br />

<strong>Devcon</strong>® Irathane® 155<br />

01/15/02<br />

South American Copper/Gold mine<br />

Mining<br />

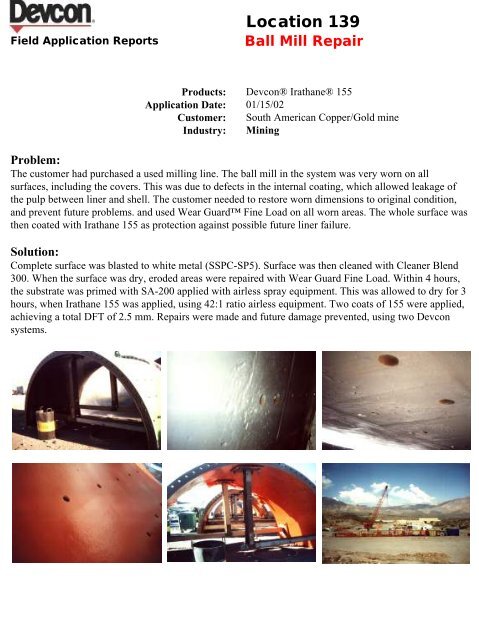

Problem:<br />

The customer had purchased a used milling line. The ball mill in the system was very worn on all<br />

surfaces, including the covers. This was due to defects in the internal coating, which allowed leakage of<br />

the pulp between liner <strong>and</strong> shell. The customer needed to restore worn dimensions to original condition,<br />

<strong>and</strong> prevent future problems. <strong>and</strong> used Wear Guard Fine Load on all worn areas. The whole surface was<br />

then coated with Irathane 155 as protection against possible future liner failure.<br />

Solution:<br />

Complete surface was blasted to white metal (SSPC-SP5). Surface was then cleaned with Cleaner Blend<br />

300. When the surface was dry, eroded areas were repaired with Wear Guard Fine Load. Within 4 hours,<br />

the substrate was primed with SA-200 applied with airless spray equipment. This was allowed to dry for 3<br />

hours, when Irathane 155 was applied, using 42:1 ratio airless equipment. Two coats of 155 were applied,<br />

achieving a total DFT of 2.5 mm. <strong>Repair</strong>s were made <strong>and</strong> future damage prevented, using two <strong>Devcon</strong><br />

systems.