Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 140<br />

Ball Mill Trunnion<br />

<strong>Repair</strong> <strong>and</strong> Lining<br />

Combo Wear, Flexane® 80 Putty<br />

July 2002<br />

South American Copper Mine<br />

Mining<br />

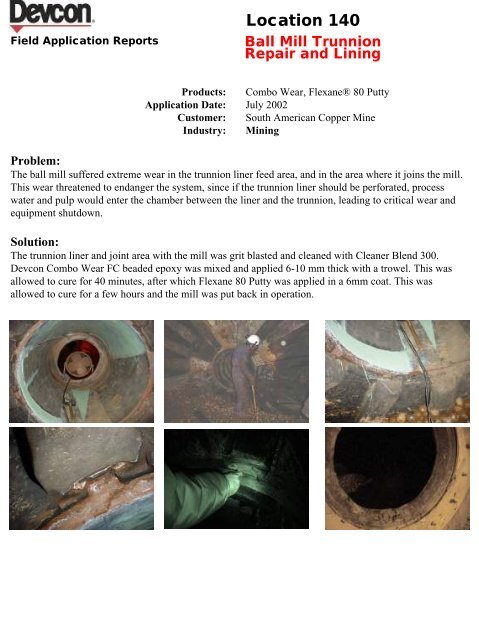

Problem:<br />

The ball mill suffered extreme wear in the trunnion liner feed area, <strong>and</strong> in the area where it joins the mill.<br />

This wear threatened to endanger the system, since if the trunnion liner should be perforated, process<br />

water <strong>and</strong> pulp would enter the chamber between the liner <strong>and</strong> the trunnion, leading to critical wear <strong>and</strong><br />

equipment shutdown.<br />

Solution:<br />

The trunnion liner <strong>and</strong> joint area with the mill was grit blasted <strong>and</strong> cleaned with Cleaner Blend 300.<br />

<strong>Devcon</strong> Combo Wear FC beaded epoxy was mixed <strong>and</strong> applied 6-10 mm thick with a trowel. This was<br />

allowed to cure for 40 minutes, after which Flexane 80 Putty was applied in a 6mm coat. This was<br />

allowed to cure for a few hours <strong>and</strong> the mill was put back in operation.