Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 86<br />

Paddle Wheel Shaft /<br />

Hub <strong>Repair</strong><br />

Titanium Putty<br />

12/18/95<br />

American Classic Voyages<br />

Transportation Marine<br />

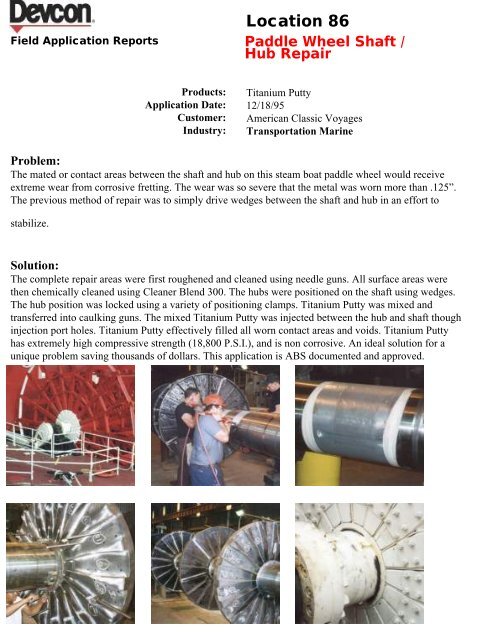

Problem:<br />

The mated or contact areas between the shaft <strong>and</strong> hub on this steam boat paddle wheel would receive<br />

extreme wear from corrosive fretting. The wear was so severe that the metal was worn more than .125”.<br />

The previous method of repair was to simply drive wedges between the shaft <strong>and</strong> hub in an effort to<br />

stabilize.<br />

Solution:<br />

The complete repair areas were first roughened <strong>and</strong> cleaned using needle guns. All surface areas were<br />

then chemically cleaned using Cleaner Blend 300. The hubs were positioned on the shaft using wedges.<br />

The hub position was locked using a variety of positioning clamps. Titanium Putty was mixed <strong>and</strong><br />

transferred into caulking guns. The mixed Titanium Putty was injected between the hub <strong>and</strong> shaft though<br />

injection port holes. Titanium Putty effectively filled all worn contact areas <strong>and</strong> voids. Titanium Putty<br />

has extremely high compressive strength (18,800 P.S.I.), <strong>and</strong> is non corrosive. An ideal solution for a<br />

unique problem saving thous<strong>and</strong>s of dollars. This application is ABS documented <strong>and</strong> approved.