Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 18<br />

Rebuild Water Circulating<br />

Pump<br />

Sprayable Ceramic Ceramic <strong>Repair</strong> Putty.<br />

February 98<br />

B G & E Power<br />

Power Plant<br />

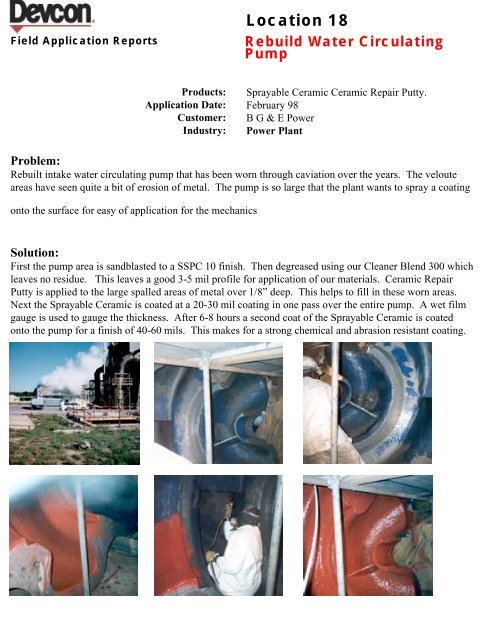

Problem:<br />

Rebuilt intake water circulating pump that has been worn through caviation over the years. The veloute<br />

areas have seen quite a bit of erosion of metal. The pump is so large that the plant wants to spray a coating<br />

onto the surface for easy of application for the mechanics<br />

Solution:<br />

First the pump area is s<strong>and</strong>blasted to a SSPC 10 finish. Then degreased using our Cleaner Blend 300 which<br />

leaves no residue. This leaves a good 3-5 mil profile for application of our materials. Ceramic <strong>Repair</strong><br />

Putty is applied to the large spalled areas of metal over 1/8” deep. This helps to fill in these worn areas.<br />

Next the Sprayable Ceramic is coated at a 20-30 mil coating in one pass over the entire pump. A wet film<br />

gauge is used to gauge the thickness. After 6-8 hours a second coat of the Sprayable Ceramic is coated<br />

onto the pump for a finish of 40-60 mils. This makes for a strong chemical <strong>and</strong> abrasion resistant coating.