Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 82<br />

Conveyor Belt <strong>Repair</strong><br />

Flexane® 80 Putty<br />

7/9/91<br />

Monroe Hard Wood<br />

Pulp <strong>and</strong> Paper Manufacturing /<br />

Lumber Manufacturing<br />

Problem:<br />

Conveyor belt was repaired by means of splicing. Splicing is often a short term repair, requiring an<br />

expensive vulcanizing repair at a later date. Water <strong>and</strong> dust can contaminate the carcass of the belt<br />

causing further damage such as fiber rotting.<br />

Solution:<br />

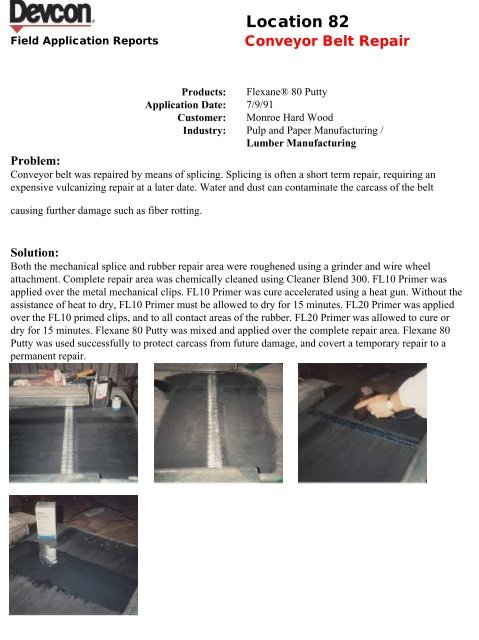

Both the mechanical splice <strong>and</strong> rubber repair area were roughened using a grinder <strong>and</strong> wire wheel<br />

attachment. Complete repair area was chemically cleaned using Cleaner Blend 300. FL10 Primer was<br />

applied over the metal mechanical clips. FL10 Primer was cure accelerated using a heat gun. Without the<br />

assistance of heat to dry, FL10 Primer must be allowed to dry for 15 minutes. FL20 Primer was applied<br />

over the FL10 primed clips, <strong>and</strong> to all contact areas of the rubber. FL20 Primer was allowed to cure or<br />

dry for 15 minutes. Flexane 80 Putty was mixed <strong>and</strong> applied over the complete repair area. Flexane 80<br />

Putty was used successfully to protect carcass from future damage, <strong>and</strong> covert a temporary repair to a<br />

permanent repair.