Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 89<br />

Valve <strong>Repair</strong><br />

Ceramic <strong>Repair</strong> Putty / Brushable Ceramic<br />

7/24/97<br />

Houston Power <strong>and</strong> Light<br />

Utility Power Generation<br />

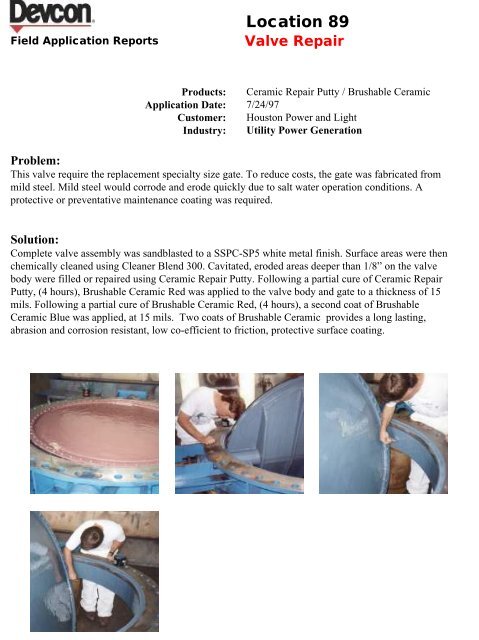

Problem:<br />

This valve require the replacement specialty size gate. To reduce costs, the gate was fabricated from<br />

mild steel. Mild steel would corrode <strong>and</strong> erode quickly due to salt water operation conditions. A<br />

protective or preventative maintenance coating was required.<br />

Solution:<br />

Complete valve assembly was s<strong>and</strong>blasted to a SSPC-SP5 white metal finish. Surface areas were then<br />

chemically cleaned using Cleaner Blend 300. Cavitated, eroded areas deeper than 1/8” on the valve<br />

body were filled or repaired using Ceramic <strong>Repair</strong> Putty. Following a partial cure of Ceramic <strong>Repair</strong><br />

Putty, (4 hours), Brushable Ceramic Red was applied to the valve body <strong>and</strong> gate to a thickness of 15<br />

mils. Following a partial cure of Brushable Ceramic Red, (4 hours), a second coat of Brushable<br />

Ceramic Blue was applied, at 15 mils. Two coats of Brushable Ceramic provides a long lasting,<br />

abrasion <strong>and</strong> corrosion resistant, low co-efficient to friction, protective surface coating.