Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 121<br />

Bag House Tube Sheet<br />

<strong>Repair</strong><br />

Plastic Steel® Putty<br />

6/33/93<br />

U.S. Steel Edgar Thompson Plant<br />

Steel Manufacturing<br />

Problem:<br />

Over months of service the weld seams, <strong>and</strong> tube sheet joints would wear from processing or filtering<br />

lime <strong>and</strong> dry dust particulate. The wear was so severe that air <strong>and</strong> material leakage occurred. Past repair<br />

procedure was to weld or reseal with RTV sealant. Both past repair procedures were time consuming <strong>and</strong><br />

offered poor performance.<br />

Solution:<br />

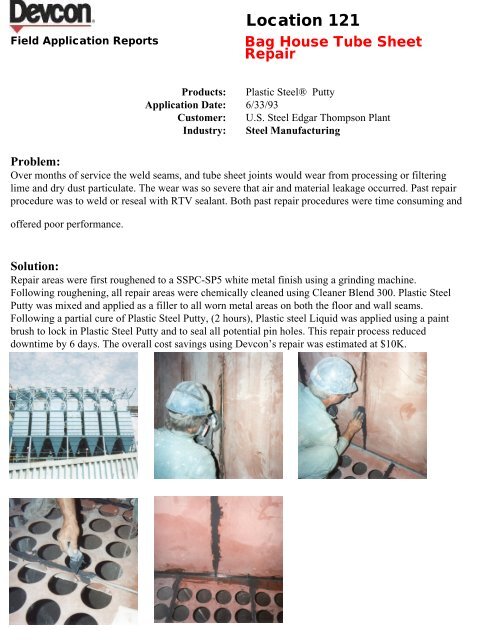

<strong>Repair</strong> areas were first roughened to a SSPC-SP5 white metal finish using a grinding machine.<br />

Following roughening, all repair areas were chemically cleaned using Cleaner Blend 300. Plastic Steel<br />

Putty was mixed <strong>and</strong> applied as a filler to all worn metal areas on both the floor <strong>and</strong> wall seams.<br />

Following a partial cure of Plastic Steel Putty, (2 hours), Plastic steel Liquid was applied using a paint<br />

brush to lock in Plastic Steel Putty <strong>and</strong> to seal all potential pin holes. This repair process reduced<br />

downtime by 6 days. The overall cost savings using <strong>Devcon</strong>’s repair was estimated at $10K.