Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 21<br />

Ball Mill In-feed Shell /<br />

Head <strong>Repair</strong><br />

Plastic Steel® B Liquid<br />

2/5/94<br />

Newmont Gold<br />

Mining<br />

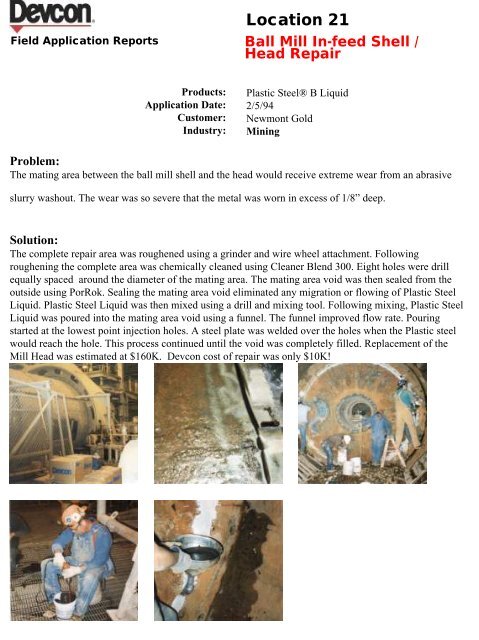

Problem:<br />

The mating area between the ball mill shell <strong>and</strong> the head would receive extreme wear from an abrasive<br />

slurry washout. The wear was so severe that the metal was worn in excess of 1/8” deep.<br />

Solution:<br />

The complete repair area was roughened using a grinder <strong>and</strong> wire wheel attachment. Following<br />

roughening the complete area was chemically cleaned using Cleaner Blend 300. Eight holes were drill<br />

equally spaced around the diameter of the mating area. The mating area void was then sealed from the<br />

outside using PorRok. Sealing the mating area void eliminated any migration or flowing of Plastic Steel<br />

Liquid. Plastic Steel Liquid was then mixed using a drill <strong>and</strong> mixing tool. Following mixing, Plastic Steel<br />

Liquid was poured into the mating area void using a funnel. The funnel improved flow rate. Pouring<br />

started at the lowest point injection holes. A steel plate was welded over the holes when the Plastic steel<br />

would reach the hole. This process continued until the void was completely filled. Replacement of the<br />

Mill Head was estimated at $160K. <strong>Devcon</strong> cost of repair was only $10K!