Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 58<br />

Rotary Bark Dryer<br />

<strong>Repair</strong><br />

Brushable Ceramic<br />

12/9/94<br />

Grant Forest Products Corporation<br />

Pulp <strong>and</strong> Paper Manufacturing<br />

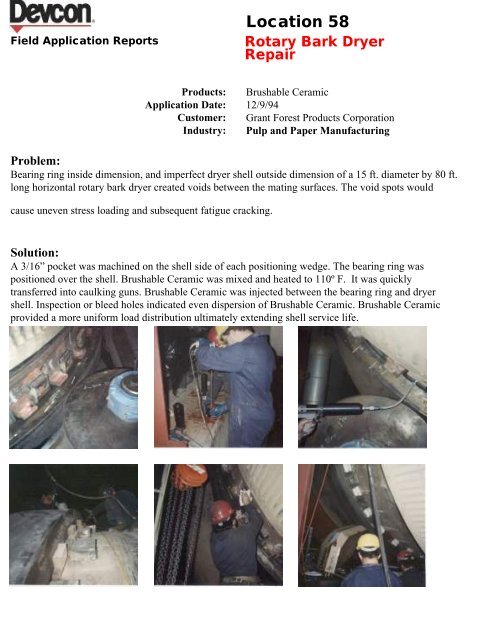

Problem:<br />

Bearing ring inside dimension, <strong>and</strong> imperfect dryer shell outside dimension of a 15 ft. diameter by 80 ft.<br />

long horizontal rotary bark dryer created voids between the mating surfaces. The void spots would<br />

cause uneven stress loading <strong>and</strong> subsequent fatigue cracking.<br />

Solution:<br />

A 3/16” pocket was machined on the shell side of each positioning wedge. The bearing ring was<br />

positioned over the shell. Brushable Ceramic was mixed <strong>and</strong> heated to 110º F. It was quickly<br />

transferred into caulking guns. Brushable Ceramic was injected between the bearing ring <strong>and</strong> dryer<br />

shell. Inspection or bleed holes indicated even dispersion of Brushable Ceramic. Brushable Ceramic<br />

provided a more uniform load distribution ultimately extending shell service life.