Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 114<br />

Coal Pulverizer <strong>Repair</strong><br />

Wear Guard High Temp<br />

8/12/97<br />

Pennsylvania Power <strong>and</strong> Light<br />

Utility Power Generation<br />

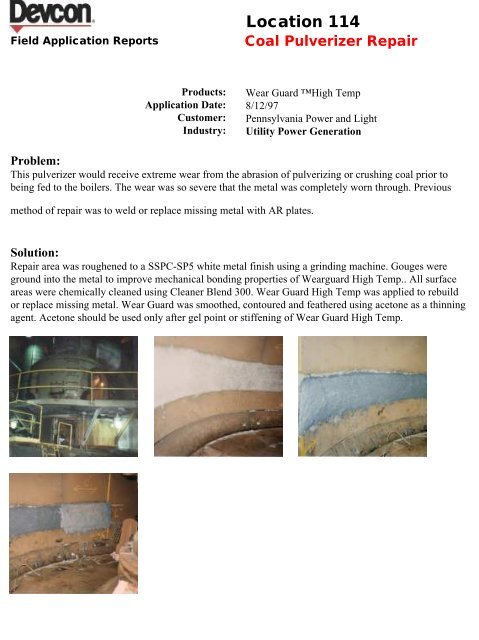

Problem:<br />

This pulverizer would receive extreme wear from the abrasion of pulverizing or crushing coal prior to<br />

being fed to the boilers. The wear was so severe that the metal was completely worn through. Previous<br />

method of repair was to weld or replace missing metal with AR plates.<br />

Solution:<br />

<strong>Repair</strong> area was roughened to a SSPC-SP5 white metal finish using a grinding machine. Gouges were<br />

ground into the metal to improve mechanical bonding properties of Wearguard High Temp.. All surface<br />

areas were chemically cleaned using Cleaner Blend 300. Wear Guard High Temp was applied to rebuild<br />

or replace missing metal. Wear Guard was smoothed, contoured <strong>and</strong> feathered using acetone as a thinning<br />

agent. Acetone should be used only after gel point or stiffening of Wear Guard High Temp.