Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Devcon Maintenance and Repair Solutions - Sintemar

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Field Application Reports<br />

Products:<br />

Application Date:<br />

Customer:<br />

Industry:<br />

Location 20<br />

Flotation Cell <strong>Repair</strong><br />

Brushable Ceramic <strong>and</strong> Ultra Quartz<br />

January 1998<br />

Nor<strong>and</strong>a Mine (Brunswick Mine Division)<br />

Mining<br />

Problem:<br />

Floatation Cells see tremendous corrosion by the fact that the ore is abrading the sides of the tanks<br />

constantly! Any coating you apply must have great abrasion resistance. Galvanic corrosion occurs at the<br />

steel surfaces rather quickly once abrasion starts! The floor of the Floatation Cell sees the sediment of the<br />

ore which is very abrasive, <strong>and</strong> needs repairing regularly.<br />

Solution:<br />

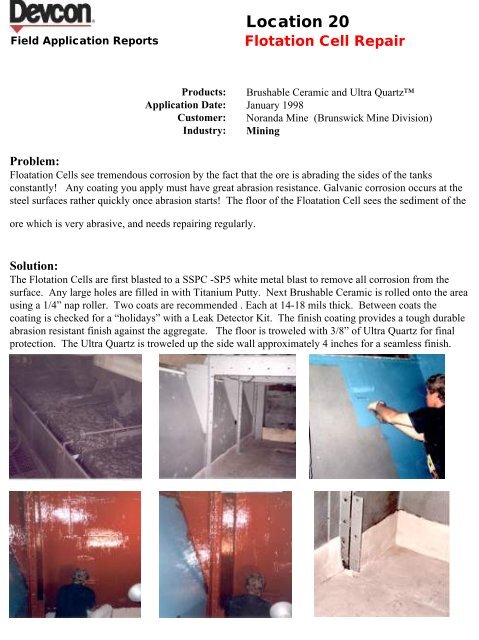

The Flotation Cells are first blasted to a SSPC -SP5 white metal blast to remove all corrosion from the<br />

surface. Any large holes are filled in with Titanium Putty. Next Brushable Ceramic is rolled onto the area<br />

using a 1/4” nap roller. Two coats are recommended . Each at 14-18 mils thick. Between coats the<br />

coating is checked for a “holidays” with a Leak Detector Kit. The finish coating provides a tough durable<br />

abrasion resistant finish against the aggregate. The floor is troweled with 3/8” of Ultra Quartz for final<br />

protection. The Ultra Quartz is troweled up the side wall approximately 4 inches for a seamless finish.