Industrialised, Integrated, Intelligent sustainable Construction - I3con

Industrialised, Integrated, Intelligent sustainable Construction - I3con

Industrialised, Integrated, Intelligent sustainable Construction - I3con

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SUSTAINABLE CONSTRUCTION HANDBOOK 2<br />

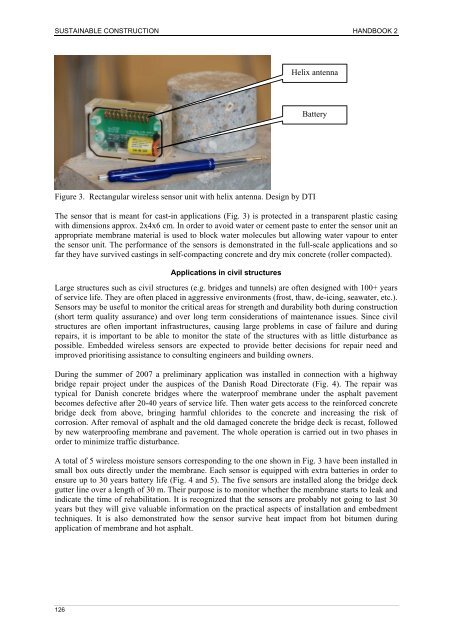

Figure 3. Rectangular wireless sensor unit with helix antenna. Design by DTI<br />

The sensor that is meant for cast-in applications (Fig. 3) is protected in a transparent plastic casing<br />

with dimensions approx. 2x4x6 cm. In order to avoid water or cement paste to enter the sensor unit an<br />

appropriate membrane material is used to block water molecules but allowing water vapour to enter<br />

the sensor unit. The performance of the sensors is demonstrated in the full-scale applications and so<br />

far they have survived castings in self-compacting concrete and dry mix concrete (roller compacted).<br />

126<br />

Applications in civil structures<br />

Helix antenna<br />

Battery<br />

Large structures such as civil structures (e.g. bridges and tunnels) are often designed with 100+ years<br />

of service life. They are often placed in aggressive environments (frost, thaw, de-icing, seawater, etc.).<br />

Sensors may be useful to monitor the critical areas for strength and durability both during construction<br />

(short term quality assurance) and over long term considerations of maintenance issues. Since civil<br />

structures are often important infrastructures, causing large problems in case of failure and during<br />

repairs, it is important to be able to monitor the state of the structures with as little disturbance as<br />

possible. Embedded wireless sensors are expected to provide better decisions for repair need and<br />

improved prioritising assistance to consulting engineers and building owners.<br />

During the summer of 2007 a preliminary application was installed in connection with a highway<br />

bridge repair project under the auspices of the Danish Road Directorate (Fig. 4). The repair was<br />

typical for Danish concrete bridges where the waterproof membrane under the asphalt pavement<br />

becomes defective after 20-40 years of service life. Then water gets access to the reinforced concrete<br />

bridge deck from above, bringing harmful chlorides to the concrete and increasing the risk of<br />

corrosion. After removal of asphalt and the old damaged concrete the bridge deck is recast, followed<br />

by new waterproofing membrane and pavement. The whole operation is carried out in two phases in<br />

order to minimize traffic disturbance.<br />

A total of 5 wireless moisture sensors corresponding to the one shown in Fig. 3 have been installed in<br />

small box outs directly under the membrane. Each sensor is equipped with extra batteries in order to<br />

ensure up to 30 years battery life (Fig. 4 and 5). The five sensors are installed along the bridge deck<br />

gutter line over a length of 30 m. Their purpose is to monitor whether the membrane starts to leak and<br />

indicate the time of rehabilitation. It is recognized that the sensors are probably not going to last 30<br />

years but they will give valuable information on the practical aspects of installation and embedment<br />

techniques. It is also demonstrated how the sensor survive heat impact from hot bitumen during<br />

application of membrane and hot asphalt.