2007 Reference document (PDF) - Valeo

2007 Reference document (PDF) - Valeo

2007 Reference document (PDF) - Valeo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Overall, <strong>Valeo</strong> used higher tonnages of packaging material<br />

than in previous years, despite efforts to cut down.<br />

In the materials mix the trend toward lower plastic consumption<br />

continues, consistent with automakers’, demands and safety<br />

considerations (plastics such as PVC and polypropylene are<br />

dropped because of fire risks).<br />

<strong>Valeo</strong> promotes the use of reusable packaging (through the use of<br />

non-disposable packs, now widespread at <strong>Valeo</strong> sites), recyclable<br />

materials (plastics) and recycled materials (plastics, papercardboard).<br />

S everal <strong>Valeo</strong> sites have taken initiatives to minimize<br />

the environmental impact of their packaging.<br />

At the Skawina site (<strong>Valeo</strong> Wiper Systems), new cardboard<br />

specifications were introduced in <strong>2007</strong>, bringing a 10% weight<br />

reduction.<br />

At the Telma site in Nanhui (<strong>Valeo</strong> Electrical Systems), a 27% weight<br />

reduction was achieved by introducing cardboard boxes to phase<br />

out wooden crates, from August <strong>2007</strong>.<br />

Many sites have their wooden palettes reconditioned by social<br />

integration organizations (typically employing handicapped people).<br />

The repaired palettes are either sold or taken back into service.<br />

Extending palette service life helps to save timber resources.<br />

In 2008, <strong>Valeo</strong> will introduce short- and medium-term<br />

quantitative targets on reducing packaging consumption<br />

for each Product Family, consistent with its specificities and<br />

practices.<br />

To support the efforts of Product Family teams, a cross-functional<br />

working group will also be set up in 2008 to examine more<br />

environmentally sound packaging solutions. Improvements<br />

will be sought through weight reductions, extended lifespans,<br />

volume/capacity optimization, choice of materials, etc.<br />

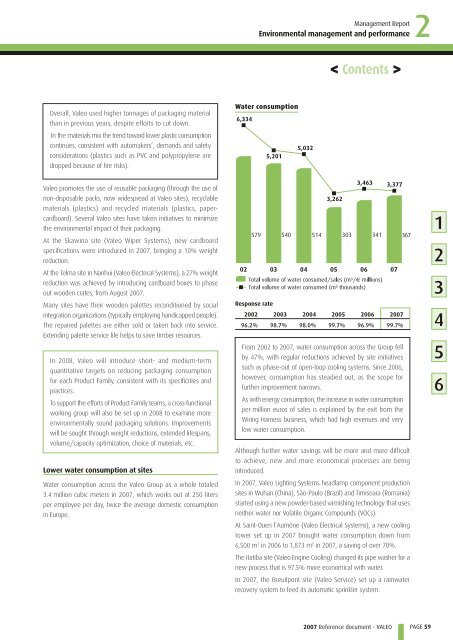

Lower water consumption at sites<br />

Water consumption across the <strong>Valeo</strong> Group as a whole totaled<br />

3.4 million cubic meters in <strong>2007</strong>, which works out at 250 liters<br />

per employee per day, twice the average domestic consumption<br />

in Europe.<br />

Management Report<br />

Environmental management and performance<br />

Water consumption<br />

< Contents ><br />

Response rate<br />

2002 2003 2004 2005 2006 <strong>2007</strong><br />

96.2% 98.7% 98.0% 99.7% 96.9% 99.7%<br />

From 2002 to <strong>2007</strong>, water consumption across the Group fell<br />

by 47%, with regular reductions achieved by site initiatives<br />

such as phase-out of open-loop cooling systems. Since 2006,<br />

however, consumption has steadied out, as the scope for<br />

further improvement narrows.<br />

As with energy consumption, the increase in water consumption<br />

per million euros of sales is explained by the exit from the<br />

Wiring Harness business, which had high revenues and very<br />

low water consumption.<br />

Alt hough further water savings will be more and more difficult<br />

to achieve, new and more economical processes are being<br />

introduced.<br />

In <strong>2007</strong>, <strong>Valeo</strong> Lighting Systems headlamp component production<br />

sites in Wuhan (China), São-Paulo (Brazil) and Timisoara (Romania)<br />

started using a new powder-based varnishing technology that uses<br />

neither water nor Volatile Organic Compounds (VOCs).<br />

At Saint-Ouen l’Aumône (<strong>Valeo</strong> Electrical Systems), a new cooling<br />

tower set up in <strong>2007</strong> brought water consumption down from<br />

6,500 m3 in 2006 to 1,873 m3 in <strong>2007</strong>, a saving of over 70%.<br />

The Itatiba site (<strong>Valeo</strong> Engine Cooling) changed its pipe washer for a<br />

new process that is 97.5% more economical with water.<br />

In <strong>2007</strong>, the Breuilpont site (<strong>Valeo</strong> Service) set up a rainwater<br />

recovery system to feed its automatic sprinkler system.<br />

<strong>2007</strong> <strong>Reference</strong> <strong>document</strong> - VALEO<br />

2<br />

PAGE 59<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6