2007 Reference document (PDF) - Valeo

2007 Reference document (PDF) - Valeo

2007 Reference document (PDF) - Valeo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2 Management<br />

PAGE 60<br />

Report<br />

Environmental management and performance<br />

In line with the objectives of the <strong>Valeo</strong> generic plant concept,<br />

each site is encouraged to implement techniques for achieving<br />

further reductions in water consumption over the years to<br />

come: leak detection, improvements in individual behavior,<br />

replacement of open-loop cooling systems, etc. Rainwater<br />

and wastewater recovery is a major avenue for case-by-case<br />

investigation.<br />

2.4. Waste production and reuse<br />

Any good waste management policy will have four focuses:<br />

at-source waste reduction (the best way to manage waste is<br />

by not producing any), sorting, recycling and disposal (under<br />

environmentally sound conditions). <strong>Valeo</strong> addresses all four issues,<br />

both in managing sites and in designing products, which will<br />

inevitably become waste at the end of their useful lives. The Group<br />

also contributes to meeting the objectives set by E uropean directive<br />

2000/53/EC on end-of-life vehicles (ELV), which specifies a 95%<br />

ELV utilization rate by January 1, 2015, with 85% through reuse<br />

and recycling.<br />

Low-waste product design<br />

<strong>Valeo</strong>’s forthcoming directive on eco-design standards seeks to<br />

minimize the environmental impact of products throughout their<br />

lifecycles. It sets out requirements on three aspects of end-of-life<br />

impact: heavy metal content, recyclability and reusability.<br />

Waste management is planned for from the initial product design<br />

stage, by minimizing the parts count, using fewer different metals,<br />

ensuring products can be dismantled easily, and giving priority to<br />

reusable products.<br />

Reduction in site waste production<br />

The Group’s main waste products are, in descending order of volume,<br />

metal, wood and plastics. Almost all metal waste (98%) is sold for<br />

recycling. Some 75% of wood is recycled and the remainder is used<br />

for heating. Two-thirds of plastic are sold for recycling.<br />

<strong>2007</strong> <strong>Reference</strong> <strong>document</strong> - VALEO<br />

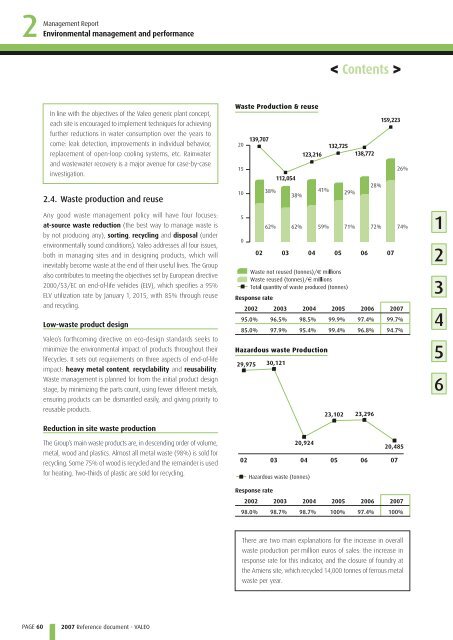

Waste Production & reuse<br />

Response rate<br />

2002 2003 2004 2005 2006 <strong>2007</strong><br />

95.0% 96.5% 98.5% 99.9% 97.4% 99.7%<br />

85.0% 97.9% 95.4% 99.4% 96.8% 94.7%<br />

Hazardous waste Production<br />

< Contents ><br />

Response rate<br />

2002 2003 2004 2005 2006 <strong>2007</strong><br />

98.0% 98.7% 98.7% 100% 97.4% 100%<br />

There are two main explanations for the increase in overall<br />

waste production per million euros of sales: the increase in<br />

response rate for this indicator, and the closure of foundry at<br />

the Amiens site, which recycled 14,000 tonnes of ferrous metal<br />

waste per year.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6