- Page 1 and 2:

MAP Mediterranean Action Plan Energ

- Page 3:

The work schedule was led and coord

- Page 7:

Executive summary Due to the divers

- Page 11 and 12:

SUMMARY REPORT 1. Introduction Summ

- Page 13 and 14:

Summary Report 50 experts took part

- Page 15 and 16:

Summary Report consumption dependin

- Page 17 and 18:

Summary Report The MSSD proposes tw

- Page 19 and 20:

Summary Report 4.2 Clean De velopme

- Page 21 and 22:

Summary Report The resources saved

- Page 23 and 24:

Summary Report Most of the countrie

- Page 25 and 26:

Summary Report buildings, or in cas

- Page 27 and 28:

Summary Report lastly, with the sup

- Page 29 and 30:

8. Attachments Attachment 1 - Activ

- Page 31 and 32:

8.2 At t a c h ment 2 - List o f pa

- Page 33 and 34:

Experts Members of the steering com

- Page 35 and 36:

Experts Members of the steering com

- Page 37 and 38:

Experts Members of the steering com

- Page 39 and 40:

Summary Report 8.3 At t a c h ment

- Page 41 and 42:

Objectives-context-mandate-partnerh

- Page 43 and 44:

DAY 2 - 30 MARCH 2007 Session 3 Rou

- Page 45 and 46:

Access to electricity Summary Repor

- Page 47 and 48:

Summary Report two greenhouse gases

- Page 49 and 50:

Summary Report an important CDM sta

- Page 51 and 52:

Summary Report 8.7 At t a c h ment

- Page 53 and 54:

Mediterranean Strategy for Sustaina

- Page 55 and 56:

Mediterranean Strategy for Sustaina

- Page 57 and 58:

Press release Workshop on "Energy a

- Page 59 and 60:

RAPPORT DE SYNTHESE 1. Introduction

- Page 61 and 62:

Rapport de synthèse d’examiner l

- Page 63 and 64:

Rapport de synthèse la région (qu

- Page 65 and 66:

Rapport de synthèse 3.2 Réponses

- Page 67 and 68:

Rapport de synthèse 4. Cadrage ré

- Page 69 and 70:

Rapport de synthèse 4.3 Les ER et

- Page 71 and 72:

Rapport de synthèse 5. Rapports na

- Page 73 and 74:

Rapport de synthèse nombreuses dan

- Page 75 and 76:

Rapport de synthèse Un autre méca

- Page 77 and 78:

Rapport de synthèse ancien. Ce pro

- Page 79 and 80:

Rapport de synthèse de soumettre

- Page 81 and 82:

8.2 An n e xe 2 - Liste des partici

- Page 83 and 84:

Rapport de synthèse PARTICIPATION

- Page 85 and 86:

Rapport de synthèse PARTICIPATION

- Page 87 and 88:

Rapport de synthèse PARTICIPATION

- Page 89 and 90:

Rapport de synthèse PARTICIPATION

- Page 91 and 92:

Rapport de synthèse PARTICIPATION

- Page 93 and 94:

Rapport de synthèse MEMBRES DU MCS

- Page 95 and 96:

En partenariat avec Commission Méd

- Page 97 and 98:

08h15-8h45 Accueil des participants

- Page 99 and 100:

Rapport de synthèse 8.4 An n e xe

- Page 101 and 102:

Rapport de synthèse côté de l’

- Page 103 and 104:

Rapport de synthèse 33) Pour l’i

- Page 105 and 106:

Rapport de synthèse 8.7 An n e xe

- Page 107 and 108:

Suivi de la Stratégie Méditerran

- Page 109 and 110:

Suivi de la Stratégie Méditerran

- Page 111 and 112:

Communiqué de presse Atelier Éner

- Page 113:

BOSNIA & HERZEGOVINA By Mrs Semra F

- Page 116 and 117:

Energy bill 90 Energy source Oil fo

- Page 118 and 119:

92 ENERGY AND SUSTAINABLE DEVELOPME

- Page 120 and 121:

Facture énergétique 94 ENERGY AND

- Page 122 and 123:

96 ENERGY AND SUSTAINABLE DEVELOPME

- Page 124 and 125:

98 ENERGY AND SUSTAINABLE DEVELOPME

- Page 126 and 127:

100 ENERGY AND SUSTAINABLE DEVELOPM

- Page 128 and 129:

102 ENERGY AND SUSTAINABLE DEVELOPM

- Page 130 and 131:

104 ENERGY AND SUSTAINABLE DEVELOPM

- Page 132 and 133:

106 ENERGY AND SUSTAINABLE DEVELOPM

- Page 134 and 135:

108 ENERGY AND SUSTAINABLE DEVELOPM

- Page 136 and 137:

110 ENERGY AND SUSTAINABLE DEVELOPM

- Page 138 and 139:

112 ENERGY AND SUSTAINABLE DEVELOPM

- Page 140 and 141:

2.2.4 Demand for electricity 114 EN

- Page 142 and 143:

116 ENERGY AND SUSTAINABLE DEVELOPM

- Page 144 and 145:

118 ENERGY AND SUSTAINABLE DEVELOPM

- Page 146 and 147:

120 ENERGY AND SUSTAINABLE DEVELOPM

- Page 148 and 149:

2.3.4 Other impacts on the environm

- Page 150 and 151:

124 ENERGY AND SUSTAINABLE DEVELOPM

- Page 152 and 153:

126 ENERGY AND SUSTAINABLE DEVELOPM

- Page 154 and 155:

128 ENERGY AND SUSTAINABLE DEVELOPM

- Page 156 and 157:

130 ENERGY AND SUSTAINABLE DEVELOPM

- Page 158 and 159:

132 ENERGY AND SUSTAINABLE DEVELOPM

- Page 160 and 161:

134 ENERGY AND SUSTAINABLE DEVELOPM

- Page 162 and 163:

136 ENERGY AND SUSTAINABLE DEVELOPM

- Page 164 and 165:

7. Table of illustrations 138 ENERG

- Page 167:

CYPRUS By M. Costas PAPASTAVROS, Mi

- Page 170 and 171:

144 ENERGY AND SUSTAINABLE DEVELOPM

- Page 173 and 174:

II. RÉSUMÉ 1. Défis et durabilit

- Page 175:

CYPRUS - Résumé d'aide ont été

- Page 178 and 179:

152 ENERGY AND SUSTAINABLE DEVELOPM

- Page 180 and 181:

154 ENERGY AND SUSTAINABLE DEVELOPM

- Page 182 and 183:

156 ENERGY AND SUSTAINABLE DEVELOPM

- Page 184 and 185:

158 ENERGY AND SUSTAINABLE DEVELOPM

- Page 186 and 187:

160 3. Moni power station ENERGY AN

- Page 188 and 189:

162 ENERGY AND SUSTAINABLE DEVELOPM

- Page 190 and 191:

164 ENERGY AND SUSTAINABLE DEVELOPM

- Page 192 and 193:

166 ENERGY AND SUSTAINABLE DEVELOPM

- Page 194 and 195:

168 ENERGY AND SUSTAINABLE DEVELOPM

- Page 196 and 197:

170 ENERGY AND SUSTAINABLE DEVELOPM

- Page 198 and 199:

172 ENERGY AND SUSTAINABLE DEVELOPM

- Page 200 and 201:

174 ENERGY AND SUSTAINABLE DEVELOPM

- Page 202 and 203:

176 ENERGY AND SUSTAINABLE DEVELOPM

- Page 204 and 205:

3.2.3 Facilitating Grid Connection

- Page 206 and 207:

Energy Conservation 180 ENERGY AND

- Page 208 and 209:

182 ENERGY AND SUSTAINABLE DEVELOPM

- Page 210 and 211:

184 ENERGY AND SUSTAINABLE DEVELOPM

- Page 212 and 213:

186 ENERGY AND SUSTAINABLE DEVELOPM

- Page 214 and 215:

3.6.2 Wind Potential (Off shore) 18

- Page 216 and 217:

190 ENERGY AND SUSTAINABLE DEVELOPM

- Page 218 and 219:

Biomass-municipal solid waste 192 E

- Page 220 and 221:

194 ENERGY AND SUSTAINABLE DEVELOPM

- Page 222 and 223:

196 ENERGY AND SUSTAINABLE DEVELOPM

- Page 224 and 225:

198 ENERGY AND SUSTAINABLE DEVELOPM

- Page 226 and 227:

200 ENERGGY AND SUSTAINABLE DEVELOP

- Page 228 and 229:

202 ENERGGY AND SUSTAINABLE DEVELOP

- Page 230 and 231:

204 ENERGY AND SUSTAINABLE DEVELOPM

- Page 232 and 233:

206 ENERGY AND SUSTAINABLE DEVELOPM

- Page 234 and 235:

208 ENERGY AND SUSTAINABLE DEVELOPM

- Page 236 and 237:

4.2 Mari Wind Farm Project 4.2.1 De

- Page 238 and 239:

4.2.3 Technology of the project Typ

- Page 240 and 241:

214 ENERGY AND SUSTAINABLE DEVELOPM

- Page 242 and 243:

216 ENERGY AND SUSTAINABLE DEVELOPM

- Page 244 and 245:

218 ENERGY AND SUSTAINABLE DEVELOPM

- Page 246 and 247:

220 ENERGY AND SUSTAINABLE DEVELOPM

- Page 248 and 249:

222 ENERGY AND SUSTAINABLE DEVELOPM

- Page 250 and 251:

224 ENERGY AND SUSTAINABLE DEVELOPM

- Page 252 and 253:

226 ENERGY AND SUSTAINABLE DEVELOPM

- Page 254 and 255:

B. Projections - Policies and Measu

- Page 257 and 258:

I. SUMMARY EGYPT - Summary 1. Egypt

- Page 259 and 260:

EGYPT - Summary To assess RUE and R

- Page 261 and 262:

II. RESUME EGYPT - Résumé 1. L’

- Page 263 and 264:

EGYPT - Résumé 5,2 MW, couvrant l

- Page 265 and 266:

III. NATIONAL STUDY EGYPT - Nationa

- Page 267 and 268:

EGYPT - National study Second, a gr

- Page 269 and 270:

Number of jobs in the energy sector

- Page 271 and 272:

EGYPT - National study Figure 2 Egy

- Page 273 and 274:

EGYPT - National study Table 3 Summ

- Page 275 and 276:

EGYPT - National study includes ens

- Page 277 and 278:

EGYPT - National study Sector 95/96

- Page 279 and 280:

EGYPT - National study 1.3.3 Evolut

- Page 281 and 282:

EGYPT - National study 17 mtoe, rea

- Page 283 and 284:

EGYPT - National study Petroleum Pe

- Page 285 and 286:

EGYPT - National study 3) A 120 MW

- Page 287 and 288:

EGYPT - National study To satisfy t

- Page 289 and 290:

EGYPT - National study More than 90

- Page 291 and 292:

EGYPT - National study negative imp

- Page 293 and 294:

Previous and current RUE programs P

- Page 295 and 296:

EGYPT - National study Developing s

- Page 297 and 298:

EGYPT - National study Egyptian aut

- Page 299 and 300:

Order and Name of Plant Zafarana (1

- Page 301 and 302:

EGYPT - National study Announcing t

- Page 303 and 304:

EGYPT - National study Table 15 Evo

- Page 305 and 306:

EGYPT - National study from CERs re

- Page 307 and 308:

EGYPT - National study The existing

- Page 309 and 310:

EGYPT - National study For Manual r

- Page 311 and 312:

EGYPT - National study The Governme

- Page 313 and 314:

EGYPT - National study Figure 8 Win

- Page 315 and 316:

EGYPT - National study achievements

- Page 317 and 318:

EGYPT - National study and the deve

- Page 319 and 320:

5. Table of illustrations EGYPT - N

- Page 321 and 322:

EGYPT - National study Figure 9 Sol

- Page 323 and 324:

EGYPT - National study Figure 11 Wi

- Page 325 and 326:

EGYPT - National study Annex II: Ev

- Page 327 and 328:

EGYPT - National study Reviewing Ta

- Page 329 and 330:

Annex IV: List of main references E

- Page 331:

ISRAEL Dr. Amit Mor, Dr. Shimon Ser

- Page 334 and 335:

308 ENERGY AND SUSTAINABLE DEVELOPM

- Page 337 and 338:

II. RÉSUMÉ 1. Défis et durabilit

- Page 339:

ISRAEL - Résumé Quelques recomman

- Page 342 and 343:

316 ENERGY AND SUSTAINABLE DEVELOPM

- Page 344 and 345:

318 ENERGY AND SUSTAINABLE DEVELOPM

- Page 346 and 347:

320 ENERGY AND SUSTAINABLE DEVELOPM

- Page 348 and 349:

322 ENERGY AND SUSTAINABLE DEVELOPM

- Page 350 and 351:

324 ENERGY AND SUSTAINABLE DEVELOPM

- Page 352 and 353:

326 ENERGY AND SUSTAINABLE DEVELOPM

- Page 354 and 355:

328 ENERGY AND SUSTAINABLE DEVELOPM

- Page 356 and 357:

330 ENERGY AND SUSTAINABLE DEVELOPM

- Page 358 and 359:

332 ENERGY AND SUSTAINABLE DEVELOPM

- Page 360 and 361:

334 ENERGY AND SUSTAINABLE DEVELOPM

- Page 362 and 363:

336 ENERGY AND SUSTAINABLE DEVELOPM

- Page 364 and 365:

338 ENERGY AND SUSTAINABLE DEVELOPM

- Page 367:

ITALY Mrs Carmen Glorioso, Mr Mario

- Page 370 and 371:

344 ENERGY AND SUSTAINABLE DEVELOPM

- Page 372 and 373:

346 ENERGY AND SUSTAINABLE DEVELOPM

- Page 374 and 375:

348 ENERGY AND SUSTAINABLE DEVELOPM

- Page 376 and 377:

350 ENERGY AND SUSTAINABLE DEVELOPM

- Page 378 and 379:

352 ENERGY AND SUSTAINABLE DEVELOPM

- Page 380 and 381:

354 ENERGY AND SUSTAINABLE DEVELOPM

- Page 382 and 383:

356 ENERGY AND SUSTAINABLE DEVELOPM

- Page 384 and 385:

358 ENERGY AND SUSTAINABLE DEVELOPM

- Page 386 and 387:

360 ENERGY AND SUSTAINABLE DEVELOPM

- Page 388 and 389:

362 ENERGY AND SUSTAINABLE DEVELOPM

- Page 390 and 391:

364 ENERGY AND SUSTAINABLE DEVELOPM

- Page 392 and 393:

366 ENERGY AND SUSTAINABLE DEVELOPM

- Page 394 and 395:

368 ENERGY AND SUSTAINABLE DEVELOPM

- Page 396 and 397:

5. Table of illustrations 370 ENERG

- Page 399 and 400:

I. SUMMARY 1. Libya Energy Situatio

- Page 401:

LIBYA - Summary in the power genera

- Page 404 and 405:

378 ENERGY AND SUSTAINABLE DEVELOPM

- Page 407 and 408:

III. NATIONAL STUDY 1. The country

- Page 409 and 410:

1.3.2 Electrical energy demand LIBY

- Page 411 and 412:

LIBYA - National study entire Libya

- Page 413 and 414:

3.1.1 Solar radiation LIBYA - Natio

- Page 415 and 416:

LIBYA - National study It was the s

- Page 417 and 418:

PV for Water pumping LIBYA - Nation

- Page 419 and 420:

3.3.2 Thermal Conversion LIBYA - Na

- Page 421 and 422:

Manufacturing Supportive: Training

- Page 423 and 424:

LIBYA - National study a yearly 35%

- Page 425 and 426:

Array output energy LIBYA - Nationa

- Page 427 and 428:

LIBYA - National study fundamental

- Page 429 and 430:

LIBYA - National study Quality cont

- Page 431 and 432:

4.3.2 Project’s Objective LIBYA -

- Page 433 and 434:

LIBYA - National study in 30 km (22

- Page 435 and 436:

LIBYA - National study 1) Low elect

- Page 437:

7. List of illustrations LIBYA - Na

- Page 441 and 442:

I. SUMMARY MALTA - Summary 1. Chall

- Page 443:

MALTA - Summary contributed to a re

- Page 446 and 447:

420 ENERGY AND SUSTAINABLE DEVELOPM

- Page 449 and 450:

III. NATIONAL STUDY 1. The energy s

- Page 451 and 452:

MALTA - National study up of differ

- Page 453 and 454:

MALTA - National study feasible pen

- Page 455 and 456:

Enemalta Corporation, 2006a MALTA -

- Page 457 and 458:

Year Used in station - MWh Consumpt

- Page 459 and 460:

MALTA - National study 1.3 Impa cts

- Page 461 and 462:

MALTA - National study new entrants

- Page 463 and 464:

MALTA - National study Set plans an

- Page 465 and 466:

g) Energy performance in buildings.

- Page 467 and 468:

MALTA - National study Figure 5 Pre

- Page 469 and 470:

Fuels and lubricants; maintenance,

- Page 471 and 472:

MALTA - National study the measures

- Page 473 and 474:

3. Product development 4. Testing a

- Page 475 and 476:

Table 2) 2.3.1 Energy Intensity MAL

- Page 477 and 478:

MALTA - National study Table 7 Fina

- Page 479 and 480:

MALTA - National study Property own

- Page 481 and 482:

MALTA - National study policies to

- Page 483 and 484:

MALTA - National study Table 8 Powe

- Page 485 and 486:

MALTA - National study Table 12 Sum

- Page 487 and 488:

MALTA - National study These tariff

- Page 489 and 490:

MALTA - National study Suri, M. Hul

- Page 491:

MAROC Berdai Mohamed, CDER (Centre

- Page 494 and 495:

468 ENERGIE ET DEVELOPPEMENT DURABL

- Page 496 and 497:

470 ENERGIE ET DEVELOPPEMENT DURABL

- Page 498 and 499:

472 ENERGIE ET DEVELOPPEMENT DURABL

- Page 500 and 501:

474 ENERGIE ET DEVELOPPEMENT DURABL

- Page 502 and 503:

476 quantité de charbon en Tonnes

- Page 504 and 505:

478 ENERGIE ET DEVELOPPEMENT DURABL

- Page 506 and 507:

Gaz Naturel 480 Quantité Butane (T

- Page 508 and 509:

1.4.1 Investissements 2007 - 2012 4

- Page 510 and 511:

484 ENERGIE ET DEVELOPPEMENT DURABL

- Page 512 and 513:

486 ENERGIE ET DEVELOPPEMENT DURABL

- Page 514 and 515:

488 ENERGIE ET DEVELOPPEMENT DURABL

- Page 516 and 517:

490 ENERGIE ET DEVELOPPEMENT DURABL

- Page 518 and 519:

492 ENERGIE ET DEVELOPPEMENT DURABL

- Page 520 and 521:

494 ENERGIE ET DEVELOPPEMENT DURABL

- Page 522 and 523:

3.2.2 Résultats et enseignements 4

- Page 524 and 525:

498 ENERGIE ET DEVELOPPEMENT DURABL

- Page 526 and 527:

500 ENERGIE ET DEVELOPPEMENT DURABL

- Page 528 and 529:

5. Bibliographie 502 ENERGIE ET DEV

- Page 530 and 531:

Annexe 1 504 ENERGIE ET DEVELOPPEME

- Page 532 and 533:

Annexe 3 506 ENERGIE ET DEVELOPPEME

- Page 534 and 535:

Annexe 5 508 ENERGIE ET DEVELOPPEME

- Page 537 and 538:

I. SUMMARY SYRIA - Summary 1. Chall

- Page 539 and 540:

II. RÉSUMÉ 1. Défis et durabilit

- Page 541:

5. Les Success stories SYRIA - Rés

- Page 544 and 545:

518 ENERGY AND SUSTAINABLE DEVELOPM

- Page 546 and 547:

520 ENERGY AND SUSTAINABLE DEVELOPM

- Page 548 and 549:

522 MINISTRY OF IRRIGATION Public E

- Page 550 and 551:

524 ENERGY AND SUSTAINABLE DEVELOPM

- Page 552 and 553:

526 Total installed capacity Steam

- Page 554 and 555:

528 Bio 25.84% ENERGY AND SUSTAINAB

- Page 556 and 557:

1-2- Thermal electricity production

- Page 558 and 559:

532 ENERGY AND SUSTAINABLE DEVELOPM

- Page 560 and 561:

534 ENERGY AND SUSTAINABLE DEVELOPM

- Page 562 and 563:

536 10 11 12 13 14 15 16 17 18 19 M

- Page 564 and 565:

538 ENERGY AND SUSTAINABLE DEVELOPM

- Page 566 and 567:

540 ENERGY AND SUSTAINABLE DEVELOPM

- Page 568 and 569:

In Electrical Distribution Side: 54

- Page 570 and 571:

544 ENERGY AND SUSTAINABLE DEVELOPM

- Page 572 and 573:

546 ENERGY AND SUSTAINABLE DEVELOPM

- Page 574 and 575:

548 ENERGY AND SUSTAINABLE DEVELOPM

- Page 576 and 577:

550 ENERGY AND SUSTAINABLE DEVELOPM

- Page 578 and 579:

552 ENERGY AND SUSTAINABLE DEVELOPM

- Page 580 and 581:

554 ENERGY AND SUSTAINABLE DEVELOPM

- Page 582 and 583:

556 ENERGY AND SUSTAINABLE DEVELOPM

- Page 584 and 585:

The main reasons of the grid loss:

- Page 586 and 587:

560 ENERGY AND SUSTAINABLE DEVELOPM

- Page 588 and 589:

562 ENERGY AND SUSTAINABLE DEVELOPM

- Page 590 and 591:

564 ENERGY AND SUSTAINABLE DEVELOPM

- Page 592 and 593:

566 ENERGY AND SUSTAINABLE DEVELOPM

- Page 594 and 595:

4.2.2 Main tools 568 ENERGY AND SUS

- Page 596 and 597:

5. List of illustrations 570 ENERGY

- Page 599 and 600:

I. SUMMARY TURKEY - Summary 1. Chal

- Page 601 and 602:

TURKEY - Summary Table 5 Present an

- Page 603 and 604:

TURKEY - Summary Figure 2 Energy an

- Page 605 and 606:

II. RESUME 1. Défis et durabilité

- Page 607 and 608:

TURKEY - Résumé Tableau 5 Product

- Page 609 and 610:

TURKEY - Résumé Figure 4 Moyenne

- Page 611 and 612:

III. NATIONAL STUDY 1. The Country

- Page 613 and 614:

TURKEY - National Study projections

- Page 615 and 616:

TURKEY - National Study Table 13 Di

- Page 617 and 618: TURKEY - National Study Table 19 Tu

- Page 619 and 620: TURKEY - National Study 3) A new re

- Page 621 and 622: TURKEY - National Study adjacent to

- Page 623 and 624: TURKEY - National Study Table 26 Pr

- Page 625 and 626: Consumption (ktoe) 70000 60000 5000

- Page 627 and 628: TURKEY - National Study (TPPs), con

- Page 629 and 630: TURKEY - National Study The state-o

- Page 631 and 632: TURKEY - National Study stable over

- Page 633 and 634: TURKEY - National Study Table 38 Ma

- Page 635 and 636: CO2 Emission (million ton) 1000 900

- Page 637 and 638: TURKEY - National Study Table 43 Wi

- Page 639 and 640: TURKEY - National Study Table 47 Th

- Page 641 and 642: TURKEY - National Study Table 50 Un

- Page 643 and 644: TURKEY - National Study Government

- Page 645 and 646: TURKEY - National Study Table 54 No

- Page 647 and 648: TURKEY - National Study could bring

- Page 649 and 650: TURKEY - National Study Figure 13 O

- Page 651 and 652: TURKEY - National Study As living s

- Page 653 and 654: TURKEY - National Study highest in

- Page 655 and 656: TURKEY - National Study Biogas syst

- Page 657 and 658: TURKEY - National Study In Turkey,

- Page 659 and 660: TURKEY - National Study Figure 18 A

- Page 661 and 662: Customer Benefits TURKEY - National

- Page 663 and 664: TURKEY - National Study Table 65 Di

- Page 665 and 666: TURKEY - National Study Figure 20 W

- Page 667: TURKEY - National Study Figure 21 F

- Page 671 and 672: TURKEY - National Study Table 72 Ma

- Page 673 and 674: TURKEY - National Study municipalit

- Page 675 and 676: TURKEY - National Study Table 75 An

- Page 677 and 678: TURKEY - National Study Table 78 Br

- Page 679 and 680: TURKEY - National Study Table 80 Pr

- Page 681 and 682: TURKEY - National Study Table 83 Pe

- Page 683 and 684: TURKEY - National Study Table 85 Tu

- Page 685 and 686: TURKEY - National Study Table 87 Op

- Page 687 and 688: TURKEY - National Study Table 94 Co

- Page 689 and 690: TURKEY - National Study Table 98 Hy

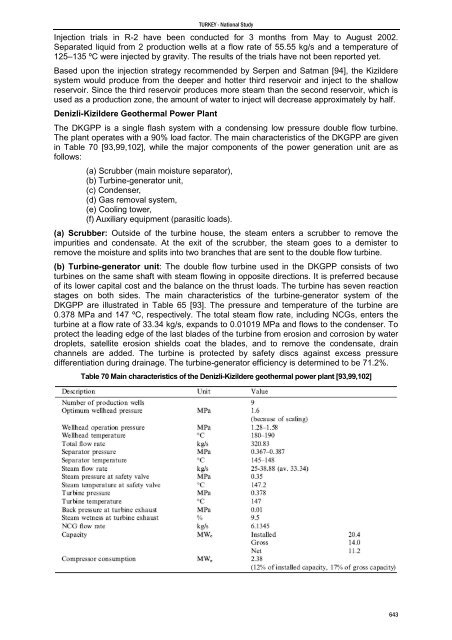

- Page 691 and 692: TURKEY - National Study Table 102 E

- Page 693 and 694: TURKEY - National Study Table 107 E

- Page 695 and 696: TURKEY - National Study Table 111 D

- Page 697 and 698: TURKEY - National Study Table 116 P

- Page 699 and 700: TURKEY - National Study [29] Kilic

- Page 701 and 702: TURKEY - National Study [85] Hepbas

- Page 703 and 704: TURKEY - National Study [140] Utlu

- Page 705 and 706: TURKEY - National Study Table 53 Va

- Page 707 and 708: LIST OF MAP TECHNICAL SERIES REPORT

- Page 709 and 710: MTS 136. UNEP/MAP/MED POL: Guidelin

- Page 711 and 712: MTS 97. UNEP/MAP/FAO: Final reports

- Page 713 and 714: MTS 58. UNEP/MAP/FAO/WHO/IAEA: Asse

- Page 715 and 716: MTS 21. UNEP/MAP/UNESCO/FAO: Eutrop