Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

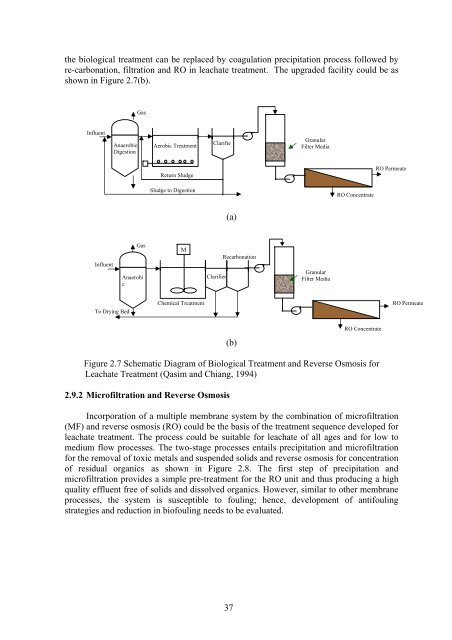

<strong>th</strong>e biological treatment can be repl<strong>ac</strong>ed by coagulation precipitation process followed by<br />

re-carbonation, filtration and RO in le<strong>ac</strong>hate treatment. The upgraded f<strong>ac</strong>ility could be as<br />

shown in Figure 2.7(b).<br />

Influent<br />

Influent<br />

Anaerobic<br />

Digestion<br />

To Drying Bed<br />

Gas<br />

Gas<br />

Anaerobi<br />

c<br />

A<br />

Aerobic Treatment<br />

Return Sludge<br />

Sludge to Digestion<br />

Clarifier<br />

(a)<br />

(b)<br />

Figure 2.7 Schematic Diagram <strong>of</strong> Biological Treatment and Reverse Osmosis for<br />

Le<strong>ac</strong>hate Treatment (Qasim and Chiang, 1994)<br />

2.9.2 Micr<strong>of</strong>iltration and Reverse Osmosis<br />

M<br />

Chemical Treatment<br />

Clarifie<br />

Recarbonation<br />

Incorporation <strong>of</strong> a multiple membrane system by <strong>th</strong>e combination <strong>of</strong> micr<strong>of</strong>iltration<br />

(MF) and reverse osmosis (RO) could be <strong>th</strong>e basis <strong>of</strong> <strong>th</strong>e treatment sequence developed for<br />

le<strong>ac</strong>hate treatment. The process could be suitable for le<strong>ac</strong>hate <strong>of</strong> all ages and for low to<br />

medium flow processes. The two-stage processes entails precipitation and micr<strong>of</strong>iltration<br />

for <strong>th</strong>e removal <strong>of</strong> toxic metals and suspended solids and reverse osmosis for concentration<br />

<strong>of</strong> residual organics as shown in Figure 2.8. The first step <strong>of</strong> precipitation and<br />

micr<strong>of</strong>iltration provides a simple pre-treatment for <strong>th</strong>e RO unit and <strong>th</strong>us producing a high<br />

quality effluent free <strong>of</strong> solids and dissolved organics. However, similar to o<strong>th</strong>er membrane<br />

processes, <strong>th</strong>e system is susceptible to fouling; hence, development <strong>of</strong> antifouling<br />

strategies and reduction in bi<strong>of</strong>ouling needs to be evaluated.<br />

37<br />

Granular<br />

Filter Media<br />

Granular<br />

Filter Media<br />

RO Concentrate<br />

RO Concentrate<br />

RO Permeate<br />

RO Permeate