Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

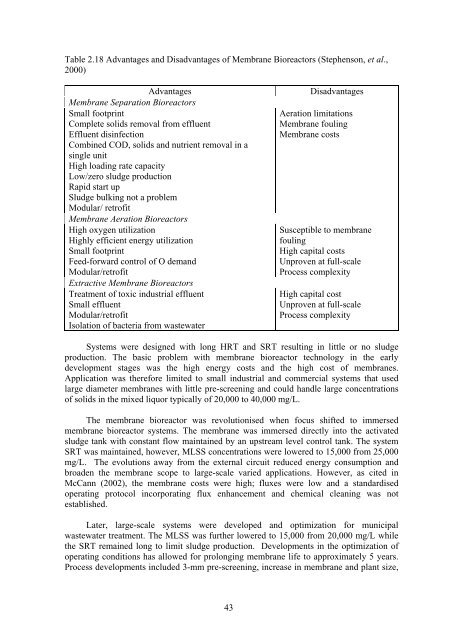

Table 2.18 Advantages and Disadvantages <strong>of</strong> Membrane Biore<strong>ac</strong>tors (Stephenson, et al.,<br />

2000)<br />

Advantages Disadvantages<br />

Membrane Separation Biore<strong>ac</strong>tors<br />

Small footprint<br />

Complete solids removal from effluent<br />

Effluent disinfection<br />

Combined COD, solids and nutrient removal in a<br />

single unit<br />

High loading rate cap<strong>ac</strong>ity<br />

Low/zero sludge production<br />

Rapid start up<br />

Sludge bulking not a problem<br />

Modular/ retr<strong>of</strong>it<br />

Membrane Aeration Biore<strong>ac</strong>tors<br />

High oxygen utilization<br />

Highly efficient energy utilization<br />

Small footprint<br />

Feed-forward control <strong>of</strong> O demand<br />

Modular/retr<strong>of</strong>it<br />

Extr<strong>ac</strong>tive Membrane Biore<strong>ac</strong>tors<br />

Treatment <strong>of</strong> toxic industrial effluent<br />

Small effluent<br />

Modular/retr<strong>of</strong>it<br />

Isolation <strong>of</strong> b<strong>ac</strong>teria from wastewater<br />

43<br />

Aeration limitations<br />

Membrane fouling<br />

Membrane costs<br />

Susceptible to membrane<br />

fouling<br />

High capital costs<br />

Unproven at full-scale<br />

Process complexity<br />

High capital cost<br />

Unproven at full-scale<br />

Process complexity<br />

Systems were designed wi<strong>th</strong> long HRT and SRT resulting in little or no sludge<br />

production. The basic problem wi<strong>th</strong> membrane biore<strong>ac</strong>tor technology in <strong>th</strong>e early<br />

development stages was <strong>th</strong>e high energy costs and <strong>th</strong>e high cost <strong>of</strong> membranes.<br />

Application was <strong>th</strong>erefore limited to small industrial and commercial systems <strong>th</strong>at used<br />

large diameter membranes wi<strong>th</strong> little pre-screening and could handle large concentrations<br />

<strong>of</strong> solids in <strong>th</strong>e mixed liquor typically <strong>of</strong> 20,000 to 40,000 mg/L.<br />

The membrane biore<strong>ac</strong>tor was revolutionised when focus shifted to immersed<br />

membrane biore<strong>ac</strong>tor systems. The membrane was immersed directly into <strong>th</strong>e <strong>ac</strong>tivated<br />

sludge tank wi<strong>th</strong> constant flow maintained by an upstream level control tank. The system<br />

SRT was maintained, however, MLSS concentrations were lowered to 15,000 from 25,000<br />

mg/L. The evolutions away from <strong>th</strong>e external circuit reduced energy consumption and<br />

broaden <strong>th</strong>e membrane scope to large-scale varied applications. However, as cited in<br />

McCann (2002), <strong>th</strong>e membrane costs were high; fluxes were low and a standardised<br />

operating protocol incorporating flux enhancement and chemical cleaning was not<br />

established.<br />

Later, large-scale systems were developed and optimization for municipal<br />

wastewater treatment. The MLSS was fur<strong>th</strong>er lowered to 15,000 from 20,000 mg/L while<br />

<strong>th</strong>e SRT remained long to limit sludge production. Developments in <strong>th</strong>e optimization <strong>of</strong><br />

operating conditions has allowed for prolonging membrane life to approximately 5 years.<br />

Process developments included 3-mm pre-screening, increase in membrane and plant size,