Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

Thesis - faculty.ait.ac.th - Asian Institute of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Where:<br />

Rt = Rm + Rn + Rc Eq. 3.2<br />

Rm = intrinsic resistance (1/m)<br />

Rn = resistance due to irreversible fouling (1/m)<br />

Rc = resistance due to cake layer (1/m)<br />

The membrane after clogging was taken out <strong>of</strong> <strong>th</strong>e re<strong>ac</strong>tor for cleaning. The<br />

membrane was first cleaned wi<strong>th</strong> tap water to remove <strong>th</strong>e cake layer att<strong>ac</strong>hing on <strong>th</strong>e<br />

membrane surf<strong>ac</strong>e follows by chemical cleaning as listed in Table 3.4 until <strong>th</strong>e membrane<br />

resistance was recovered to <strong>th</strong>e initial membrane resistance.<br />

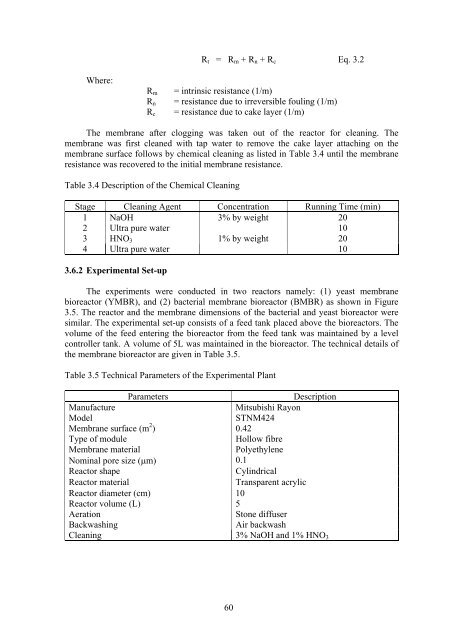

Table 3.4 Description <strong>of</strong> <strong>th</strong>e Chemical Cleaning<br />

Stage Cleaning Agent Concentration Running Time (min)<br />

1 NaOH 3% by weight 20<br />

2 Ultra pure water 10<br />

3 HNO3 1% by weight 20<br />

4 Ultra pure water 10<br />

3.6.2 Experimental Set-up<br />

The experiments were conducted in two re<strong>ac</strong>tors namely: (1) yeast membrane<br />

biore<strong>ac</strong>tor (YMBR), and (2) b<strong>ac</strong>terial membrane biore<strong>ac</strong>tor (BMBR) as shown in Figure<br />

3.5. The re<strong>ac</strong>tor and <strong>th</strong>e membrane dimensions <strong>of</strong> <strong>th</strong>e b<strong>ac</strong>terial and yeast biore<strong>ac</strong>tor were<br />

similar. The experimental set-up consists <strong>of</strong> a feed tank pl<strong>ac</strong>ed above <strong>th</strong>e biore<strong>ac</strong>tors. The<br />

volume <strong>of</strong> <strong>th</strong>e feed entering <strong>th</strong>e biore<strong>ac</strong>tor from <strong>th</strong>e feed tank was maintained by a level<br />

controller tank. A volume <strong>of</strong> 5L was maintained in <strong>th</strong>e biore<strong>ac</strong>tor. The technical details <strong>of</strong><br />

<strong>th</strong>e membrane biore<strong>ac</strong>tor are given in Table 3.5.<br />

Table 3.5 Technical Parameters <strong>of</strong> <strong>th</strong>e Experimental Plant<br />

Parameters Description<br />

Manuf<strong>ac</strong>ture Mitsubishi Rayon<br />

Model STNM424<br />

Membrane surf<strong>ac</strong>e (m 2 ) 0.42<br />

Type <strong>of</strong> module Hollow fibre<br />

Membrane material Polye<strong>th</strong>ylene<br />

Nominal pore size (µm) 0.1<br />

Re<strong>ac</strong>tor shape Cylindrical<br />

Re<strong>ac</strong>tor material Transparent <strong>ac</strong>rylic<br />

Re<strong>ac</strong>tor diameter (cm) 10<br />

Re<strong>ac</strong>tor volume (L) 5<br />

Aeration Stone diffuser<br />

B<strong>ac</strong>kwashing Air b<strong>ac</strong>kwash<br />

Cleaning 3% NaOH and 1% HNO3<br />

60